System Maintenance

www.DaikinApplied.com 93

IOM 1242-8 • PATHFINDER

®

MODEL AWV CHILLERS

Cleaning Microchannel Aluminum Coils

Maintenance consists primarily of the routine removal of dirt

and debris from the outside surface of the fins.

WARNING

Prior to cleaning the unit, turn off and lock out the main power

switch to the unit and open all access panels.

Remove Surface Loaded Fibers

Surface loaded fibers or dirt should be removed prior to water

rinse to prevent further restriction of airflow. If unable to back

wash the side of the coil opposite that of the coils entering air

side, then surface loaded fibers or dirt should be removed with

a vacuum cleaner. If a vacuum cleaner is not available, a soft

non-metallic bristle brush may be used. In either case, the tool

should be applied in the direction of the fins. Coil surfaces can

be easily damaged (fin edges bent over) if the tool is applied

across the fins.

NOTE:

Use of a water stream, such as a hose, against a

surface loaded coil will drive the fibers and dirt into

the coil. This will make cleaning efforts more difficult.

Surface loaded fibers must be completely removed

prior to using low velocity clean water rinse.

Periodic Clean Water Rinse

A monthly clean water rinse is recommended for all coils

according to

. Coils should be rinsed with water at a

lower pressure such as from a hose. Pressure washers are not

recommended as the higher pressure may damage the fins.

Regular water rinsing of epoxy coated coils that are applied in

coastal or industrial environments will help to remove chlorides,

dirt and debris. An elevated water temperature (not to exceed

130ºF) will reduce surface tension, increasing the ability to

remove chlorides and dirt.

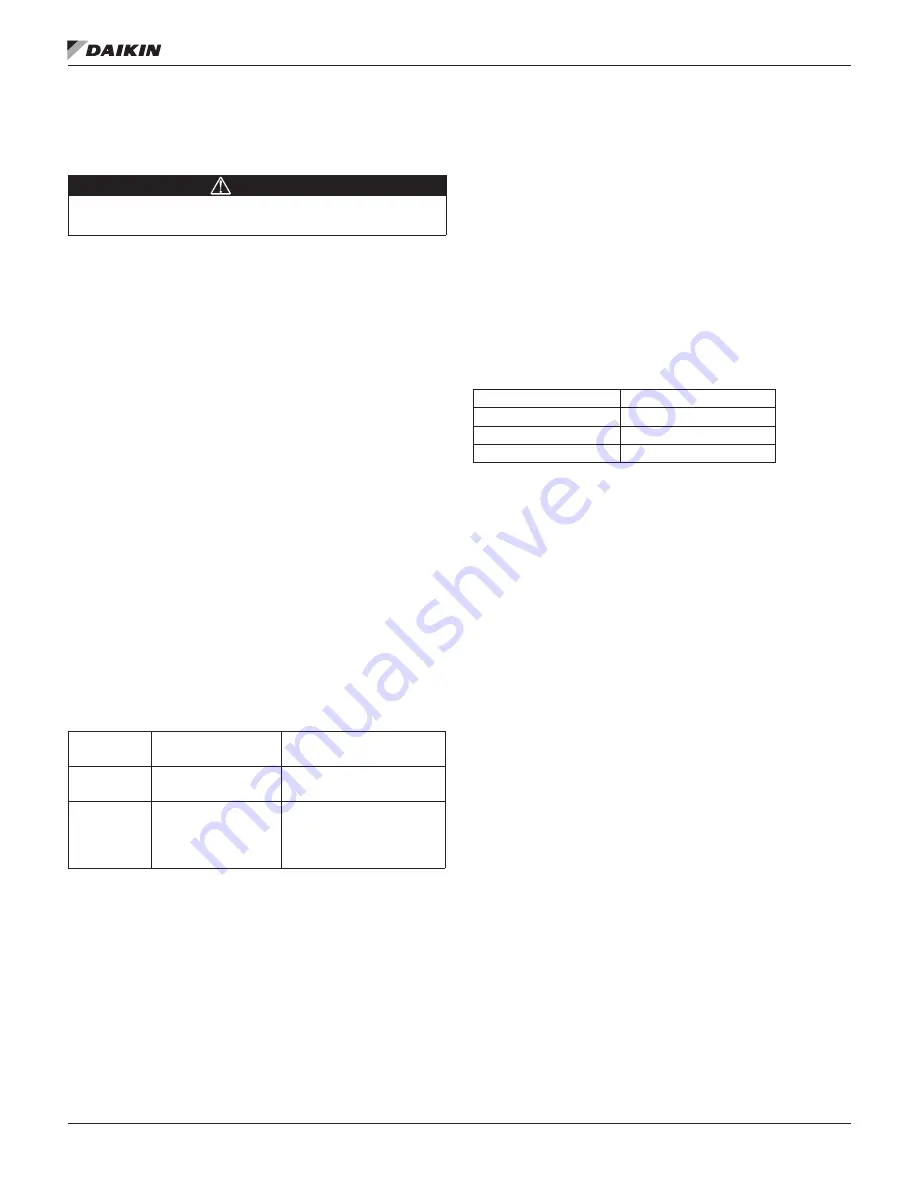

Table 62: Coil Cleaning Guidelines

Coating

Option

Recommended

Rinsing

Required Cleaning

Aluminum

Coil Only

Monthly with low

pressure water only N/A

Epoxy

Coated Coil

Monthly with low

pressure water only

- max 130°F

Quarterly with approved

cleaner, Choride

Remover is required -

max 130°F

Cleaning Epoxy Coated Coils

The following cleaning procedures are recommended as part

of the routine maintenance activities for epoxy coated coils.

Documented routine cleaning of epoxy coated coils is required

to maintain warranty coverage.

Routine Quarterly Cleaning of Epoxy Coil

Quarterly cleaning is essential to extend the life of an epoxy

coated coil and shall be part of the unit’s regularly scheduled

maintenance procedures. Failure to clean epoxy coated coils

will void the warranty and may result in reduced efficiency and

durability in the environment.

For routine quarterly cleaning, first clean the coil with a coil

). After cleaning the coils with a cleaning

agent, use the chloride remover to remove soluble salts and

revitalize the unit.

Recommended Coil Cleaning Agents

The following cleaning agents, used in accordance with the

manufacturer’s directions on the container for proper mixing

and cleaning, have been approved for use on epoxy coated

coils to remove mold, mildew, dust, soot, greasy residue, lint

and other particulate:

Table 63: Epoxy Coated Coil Recommended Cleaning

Agents

Chemical Type

Cleaning Agent

Coil Cleaner

Enviro-Coil Concentrate

Coil Cleaner

GulfCoat™

Chloride Remover

CHLOR*RID

®

Chloride remover should be used to remove soluble salts from

epoxy coated coils, but the directions must be followed closely.

This product is intended to remove chlorides and sulfates and

not intended for use as a degreaser. Any grease or oil film

should first be removed with the approved cleaning agent.

1. Remove Barrier - Soluble salts adhere themselves

to the substrate. For the effective use of this product,

the product must be able to come in contact with the

salts. These salts may be beneath any soils, grease or

dirt; therefore, these barriers must be removed prior to

application of this product. As in all surface preparation,

the best work yields the best results.

2. Apply chloride remover directly onto the substrate.

Sufficient product must be applied uniformly across the

substrate to thoroughly wet out surface with no areas

missed. This may be accomplished by use of a pump-

up sprayer. The method does not matter, as long as the

entire area to be cleaned is wetted. After the substrate

has been thoroughly wetted, the salts will be soluble and

is now only necessary to rinse them off.

3. Rinse - It is highly recommended that a hose be used as

a pressure washer will damage the fins. The water used

for the rinse is recommended to be of potable quality,

though a lesser quality of water may be used if a small

amount of chloride remover is added.

Harsh Chemical and Acid Cleaners

Harsh chemicals, household bleach or acid cleaners should

not be used to clean outdoor or indoor epoxy coated coils.

These cleaners can be very difficult to rinse out of the coil and

can accelerate corrosion and attack the epoxy coating. If there

is dirt below the surface of the coil, use the recommended coil

cleaners as described above.