System Maintenance

www.DaikinApplied.com 95

IOM 1242-8 • PATHFINDER

®

MODEL AWV CHILLERS

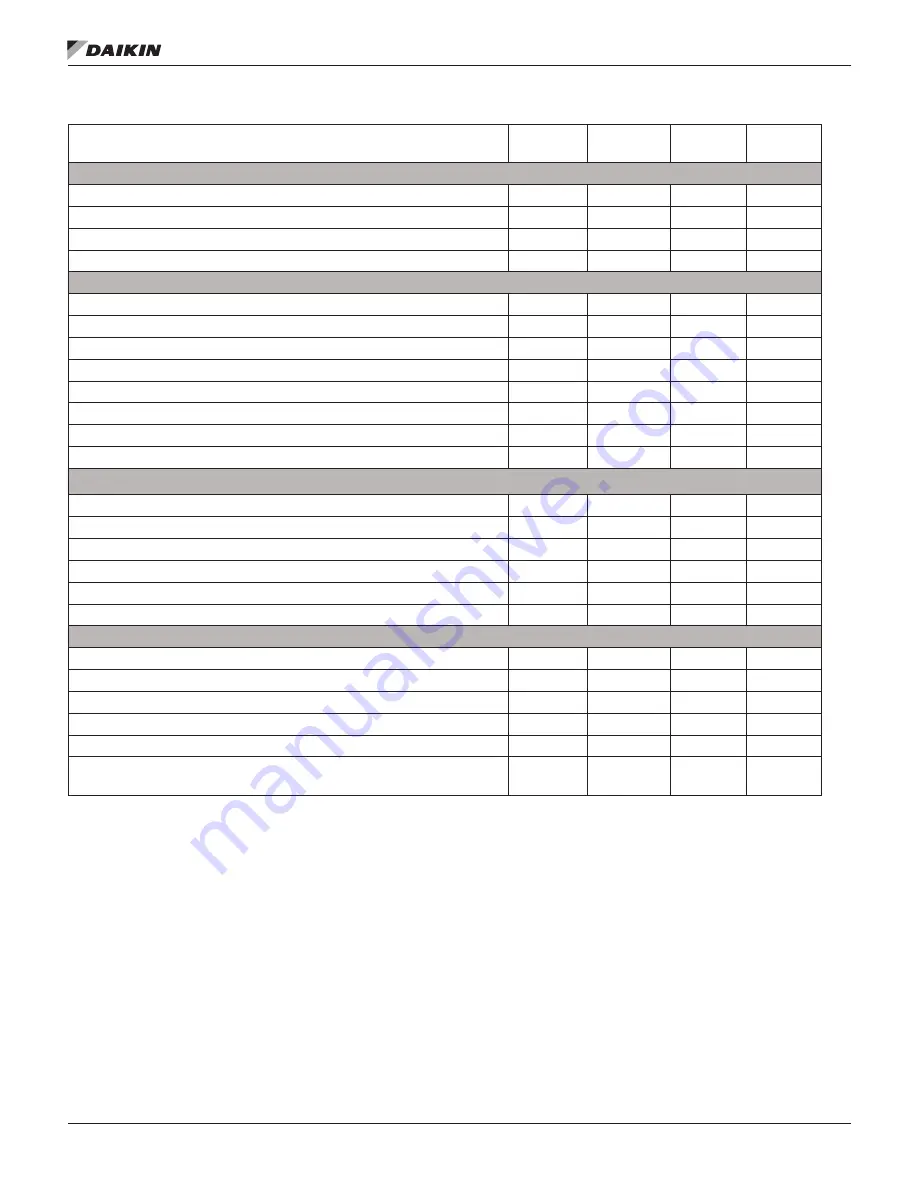

Table 65: Preventative Maintenance Schedule

Operation

Weekly

Monthly

(Note 1)

Quarterly

Annual

(Note 2)

General

Complete unit log and review (Note 3)

X

Inspect unit for loose or damaged components and visible leaks

X

Inspect thermal insulation for integrity

X

Clean and paint as required

X

Electrical ( * including the VFDs)

Sequence test controls *

X

Check contactors for pitting, replace as required *

X

Check terminals for tightness, tighten as necessary *

X

Verify solenoid plug(s) tightness and gasket integrity

X

Clean control panel interior *

X

Clean control box fan filter * (Note 7 )

X

Visually inspect components for signs of overheating *

X

Verify compressor and oil heater operation

X

Refrigeration/Lubricant

Leak test

X

Check liquid line sight glasses for clear flow

X

Check compressor oil sight glass for correct level (lubricant charge)

X

Check filter-drier pressure drop (Note 6)

X

Perform compressor vibration test (optional)

X

Perform oil analysis test on compressor oil

X

Condenser (air-cooled)

Rinse condenser coils (Note 4)

X

Clean epoxy coated condenser coils (Note 4)

X

Check fan blades for tightness on shaft (Note 5)

X

Check fans for loose rivets and cracks, check motor brackets

X

Check coil fins for damage and straighten as necessary

X

For IWSE coils, torque all hose clamp connections to a minimum of 7

ft-lbs (84 in-lbs)

X

NOTE:

1 Monthly operations include all weekly operations.

2 Annual (or spring startup) operations include all weekly, monthly, and quarterly operations.

3 Log readings can be taken daily for a higher level of unit observation.

4 Coil rinsing and cleaning can be required more frequently in areas with a high level of airborne particles.

5 Be sure fan motors are electrically locked out.

6 Replace the filter if pressure drop exceeds 20 psi.

7 The weekly fan filter cleaning schedule can be modified to meet job conditions. It is important that the filter allows full

air flow.