Installation and Application Considerations

www.DaikinApplied.com 21

IOM 1242-8 • PATHFINDER

®

MODEL AWV CHILLERS

200 gpm equals 20 gpm change per minute, or a minimum of

three minutes to go from maximum to desired flow.

Ice Mode

Optional double evaporator insulation is recommended for ice

mode operation. The standard controller software will require

“ice” set point changes and a digital signal into the controller

is required to change to the ice mode and back to standard

cooling. See the Field Wiring Diagrams on

page 24 and

for the connection location. In ice mode, the unit

will operate at full load until the shutoff temperature set point is

reached.

Glycol Solutions

The installed glycol level must align with the rated glycol

percentage indicated on the submitted chiller technical data

sheet. Failure to adhere to the rated glycol percentage may

result in unit damage and loss of unit warranty

Test fluid with a clean, accurate glycol solution hydrometer

(similar to that found in service stations) or refractometer

to determine the freezing point. On glycol applications, the

supplier normally recommends that a minimum of 25% solution

by weight be used for protection against corrosion or that

additional inhibitors should be employed.

CAUTION

Do not use automotive grade antifreeze. Industrial grade

glycols must be used. Automotive antifreeze contains

inhibitors that will cause plating on the copper tubes within the

chiller evaporator. The type and handling of glycol used must

be consistent with local codes.

Performance Adjustment Factors

AWV chillers are designed to operate with leaving antifreeze

solution temperatures per software range limits. Consult the

local Daikin Applied sales office for performance outside

these temperatures. Leaving chilled fluid temperatures below

40°F (4.4°C) result in evaporating temperatures at or below

the freezing point of water and a glycol solution is required.

MicroTech

®

III control inhibits compressor unloading at leaving

fluid temperatures below 25°F (-3.9°C).

Low fluid temperatures or high equipment room humidity for

remote evaporators may require optional double evaporator

insulation. The system designer should determine its necessity.

The use of glycol will reduce unit performance depending on its

concentration and should be considered during initial system

design.

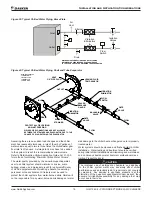

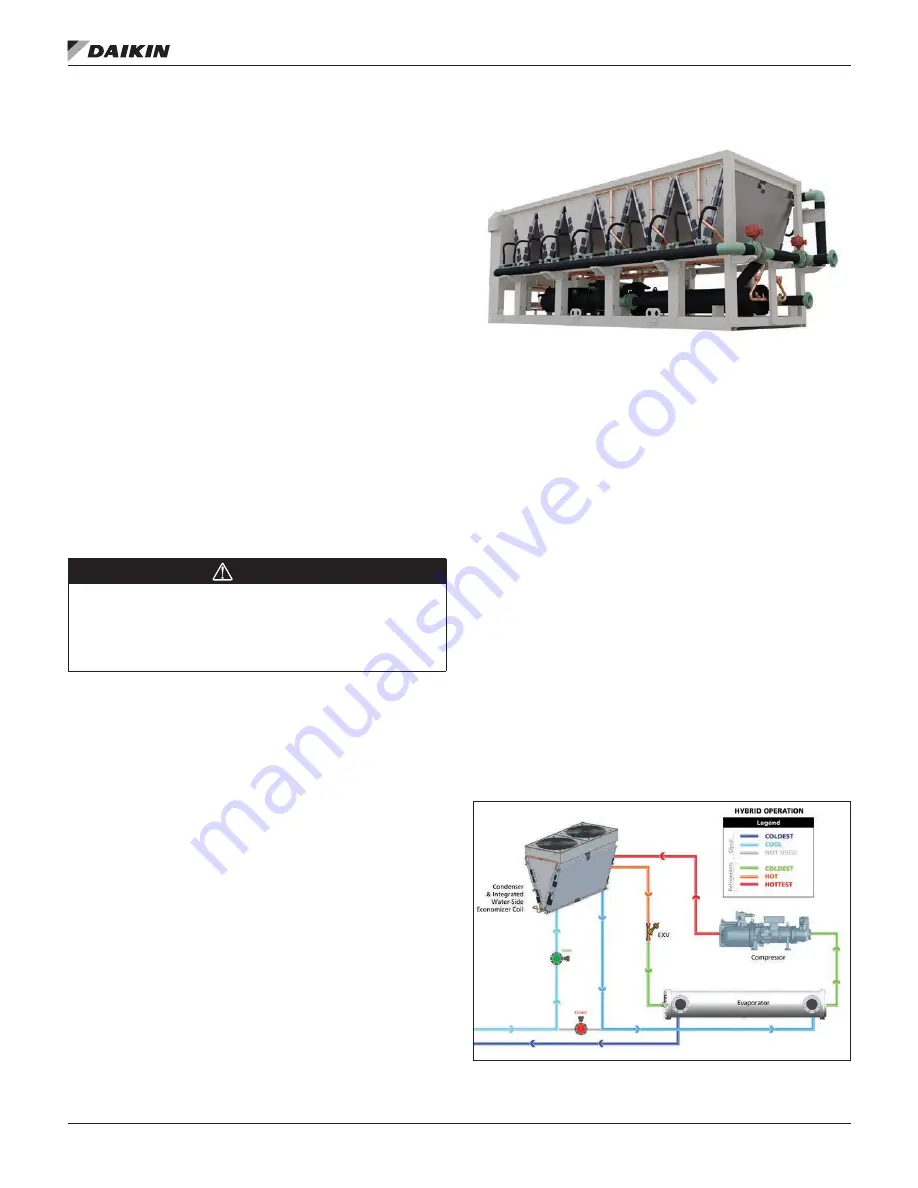

Figure 41: Integrated Waterside Economizer Option -

Representative Model

Integrated Waterside Economizer

Pathfinder Model AWV chillers with an integrated system of

waterside economizer coils may be able to satisfy 100% of

cooling load without starting a compressor or may run in full

mechanical operating mode.

cooling only mode which would be necessary for high

ambient temperatures. Cooling from the integrated waterside

economizer (IWSE) coils,

outdoor air temperature is colder than the fluid temperature

requirements. The minimum operating ambient is -20°F

(-28.9°C).

The unit controller automatically adjusts two 2-way control

valves to bring the IWSE coils in or out of the loop. Bypassing

the IWSE coils during mechanical operation only mode avoids

the additional pressure drop from the economizer coils.

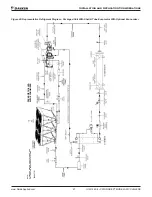

Hybrid cooling mode operation further maximizes the efficiency

of the system by rejecting some heat to the IWSE coils before

sending the fluid to the evaporator. The mechanical cooling

loop will further cool the fluid to the required setpoint but will

use much less energy.

shows how the two loops

work together in hybrid cooling mode.

Figure 42: Hybrid Cooling Mode Operation