IOM 1242-8 • PATHFINDER

®

MODEL AWV CHILLERS

62 www.DaikinApplied.com

Circuit Functions

Circuit Functions

Circuit Functions

Components controlled at the circuit level include:

• Compressor VFD

• Compressor VR Solenoid Valves

• Evaporator EXV

• Economizer EXV

• Liquid Line Solenoid Valve

• Liquid Injection Solenoid Valve

• Condenser Fans

Calculations

Calculations are for each circuit.

Approach Values

Evaporator Approach = LWT – Evap Saturated Temp

Condenser Approach = Cond Saturated Temp – OAT

Superheat Values

Suction superheat = Suction Temp – Evap Saturated Temp

Discharge superheat = Discharge Temp – Cond Saturated

Temp

Economizer Superheat = Econ Temp – Econ Saturated Temp

Differential Pressure Values

Oil Pressure Differential = Cond Pressure - Oil Pressure

Pressure Difference = Cond Pressure – Evap Pressure

Pressure Ratio

Pressure Ratio = (Cond Press +101.325) ÷ (Evap Press +

101.325)

Feedback Capacity

Feedback capacity is a representation of the actual capacity as

a percentage of full capacity based on feedback regarding the

actual speed of the compressor.

Compressors vary capacity via changes to the speed. The

actual compressor speed is read from the VFD. Feedback

capacity for a compressor with a VFD is:

Actual Compressor Speed x 100 ÷ Maximum Speed

Saturated Condenser Temperature Limit

The maximum saturated condenser temperature calculation

is based on the compressor operational envelope. This value

is used for triggering high condenser pressure alarms and as

a reference for the trigger values of the high pressure hold

and unload events. Chiller software is designed to calculate

a dynamic maximum saturated condenser temperature.

High saturated condenser hold and unload offset values are

described as follows.

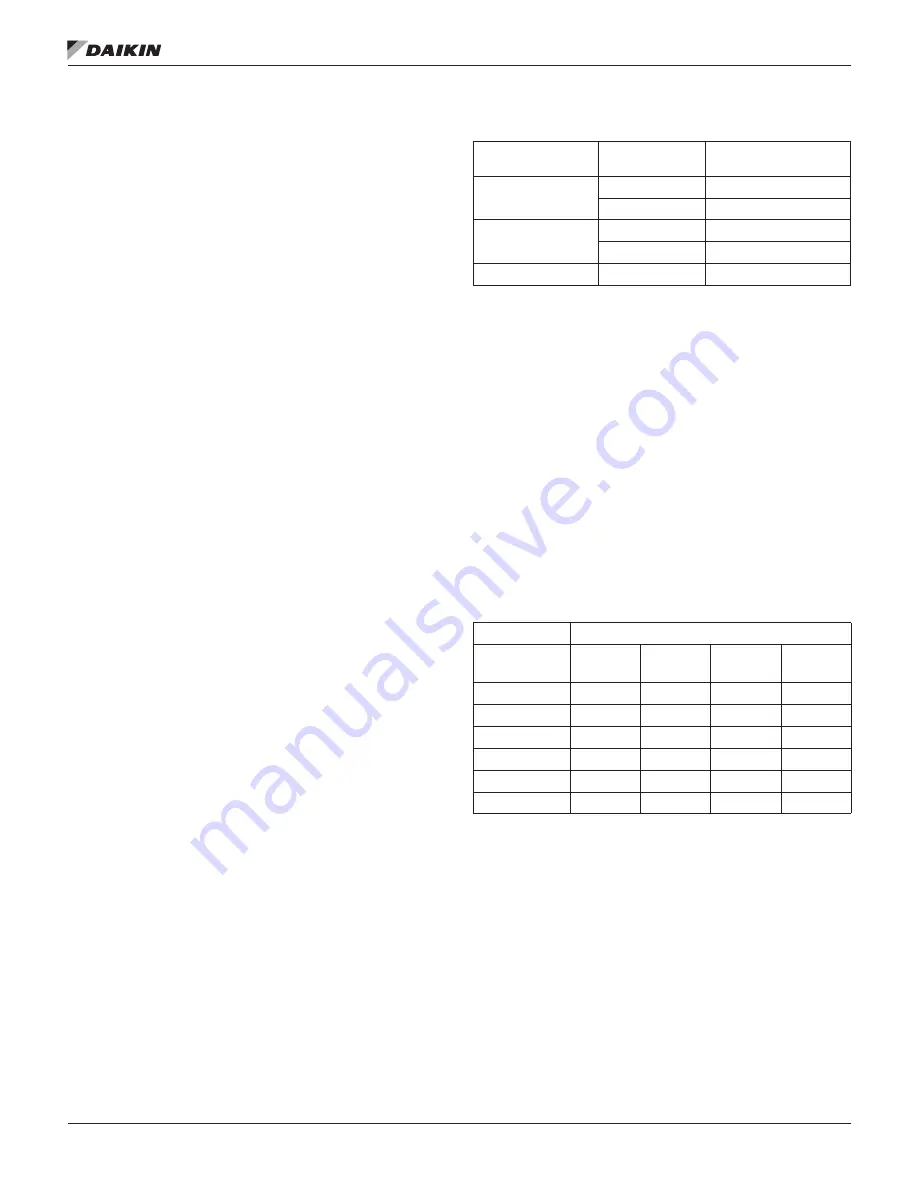

Table 52: Saturated Condenser Temperature Conditions

Condition

Saturated Evap

Temp or LWT

Max Cond Saturated

Temp (°C)

EXV state is Start

Pressure Control

LWT

≤ 0

°C

1.589 X LWT + 68.3

LWT > 0°C

68.3

EXV state is SSH

or MOP Control

Te

≤ 0

°C

1.589 X Te + 68.3

Te > 0°C

68.3

All other conditions

n/a

68.3

High Saturated Condenser – Hold Value

High Cond Hold Value = Max Saturated Cond Value – High

Cond Press Hold Offset set point

High Saturated Condenser – Unload Value

High Cond Unload Value = Max Saturated Cond Value – High

Cond Press Unload Offset set point

Maximum Compressor VFD Output

Current

Max Motor Current = Minimum of (VFD Rated Current, Motor

Rated Current)

where:

- VFD Rated Current is read from the compressor VFD

- Motor Rated Current is determined by the compressor type

and the voltage configuration:

Motor Rated Current (Amps)

Compressor

Type

380V

400V

460V

575V

F3ALVVR60

222.8

222.8

183.3

167.0

F3ALVVR86

375.6

375.6

311

253.5

F3BLVVR86

527.9

527.9

434.1

N/A

F4ALVVR80

692.1

692.1

574.8

N/A

3120

175

175

175

175

3122

230

230

230

230

Pumpdown Target Value

The pressure target for pumpdown when the circuit enters the

pumpdown state is selected as follows:

If Service Pumpdown set point = Disable

Then Pumpdown Target = Evaporator Pressure at

pumpdown start – 20 kPa with value limited to the range

from 35 kPa to the Pumpdown Pressure Max set point

If Service Pumpdown set point = Enable

Then Pumpdown Target = 35 kPa