Installation and Application Considerations

www.DaikinApplied.com

7

IOM 1242-8 • PATHFINDER

®

MODEL AWV CHILLERS

Installation and Application Considerations

Nameplates

Identification nameplates on the chiller:

• The unit nameplate is located on the exterior of the Unit

Power Panel. Both the Model No. and Serial No. are

located on the unit nameplate; the Serial No. is unique to

the unit. These numbers should be used to identify the

unit for service, parts, or warranty questions. This plate

also has the unit refrigerant charge and electrical ratings.

• Vessel nameplate is located on the evaporator. They

have a National Board Number (NB) and a serial number,

either of which identify the vessel (but not the entire unit).

• Compressor nameplate is located on each compressor

and gives pertinent electrical information.

Receiving and Handling

The unit should be inspected immediately after receipt for

possible damage. All Daikin Applied screw air-cooled chillers

are shipped FOB factory and all claims for handling and

shipping damage are the responsibility of the consignee.

Startup by a Daikin Applied service representative is included

on all Pathfinder

®

units sold for installation within the U.S.

and Canada and must be performed by them to initiate the

standard Limited Product Warranty. Startup by any party other

than a Daikin Applied service representative will void the

Limited Product Warranty. Two-week prior notification of startup

is required. The contractor should obtain a copy of the Startup

Scheduled Request Form from the sales representative or from

the nearest Daikin Applied service office. Completed Request

Form and check list on page 3 are required before startup can

be scheduled.

Installation and maintenance are to be performed only by

qualified personnel who are familiar with local codes and

regulations, and experienced with this type of equipment.

CAUTION

Extreme care must be used when rigging the unit to prevent

damage to the control panels and unit frame. Refer to the as-

built submittal drawings provided by a Daikin Applied sales

representative for configuration-specific details including

dimensions, weights, and center of gravity of the unit.

WARNING

When around sharp edges, wear appropriate Personal

Protective Equipment (PPE), such as gloves, protective

clothing, foot wear, eye protection etc. to prevent personal

injury.

WARNING

Escaping refrigerant can displace air and cause suffocation.

Immediately evacuate and ventilate the equipment area.

If the unit is damaged, follow Environmental Protection

Agency (EPA) requirements. Do not expose sparks, arcing

equipment, open flame or other ignition source to the

refrigerant.

DANGER

Improper rigging, lifting, or moving of a unit can result in

property damage, severe personal injury or death. Follow

rigging and moving instructions carefully.

Avoid rough handling shock due to impact or dropping the unit.

Do not push or pull the unit. Never allow any part of the unit

to fall during unloading or moving as this can result in serious

damage.

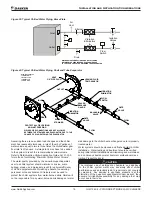

To lift a standard AWV unit, lifting tabs with 3” (76 mm)

diameter holes are provided on the base of the unit. All lifting

holes must be used when lifting the unit. Spreader bars and

cables should be arranged to prevent damage to the unit. (see

).

Figure 1: Rigging for Standard AWV Unit

NOTE:

1. Crosswise and lengthwise spreader bars must be

used to avoid damage to unit. The spreader bars in

are a representation only and may not reflect

the appearance of the actual spreader bars needed.

2. Unit with 8 lifting points illustrated above; the actual

unit configuration may vary from this diagram. See

“Dimensional Drawings” on page 38

for general

lifting locations. Drawings, dimensional values,

weights, and other information may change depending

on options or configurations selected. Refer to the as-

built submittal drawings provided by a Daikin Applied

sales representative for configuration-specific details.

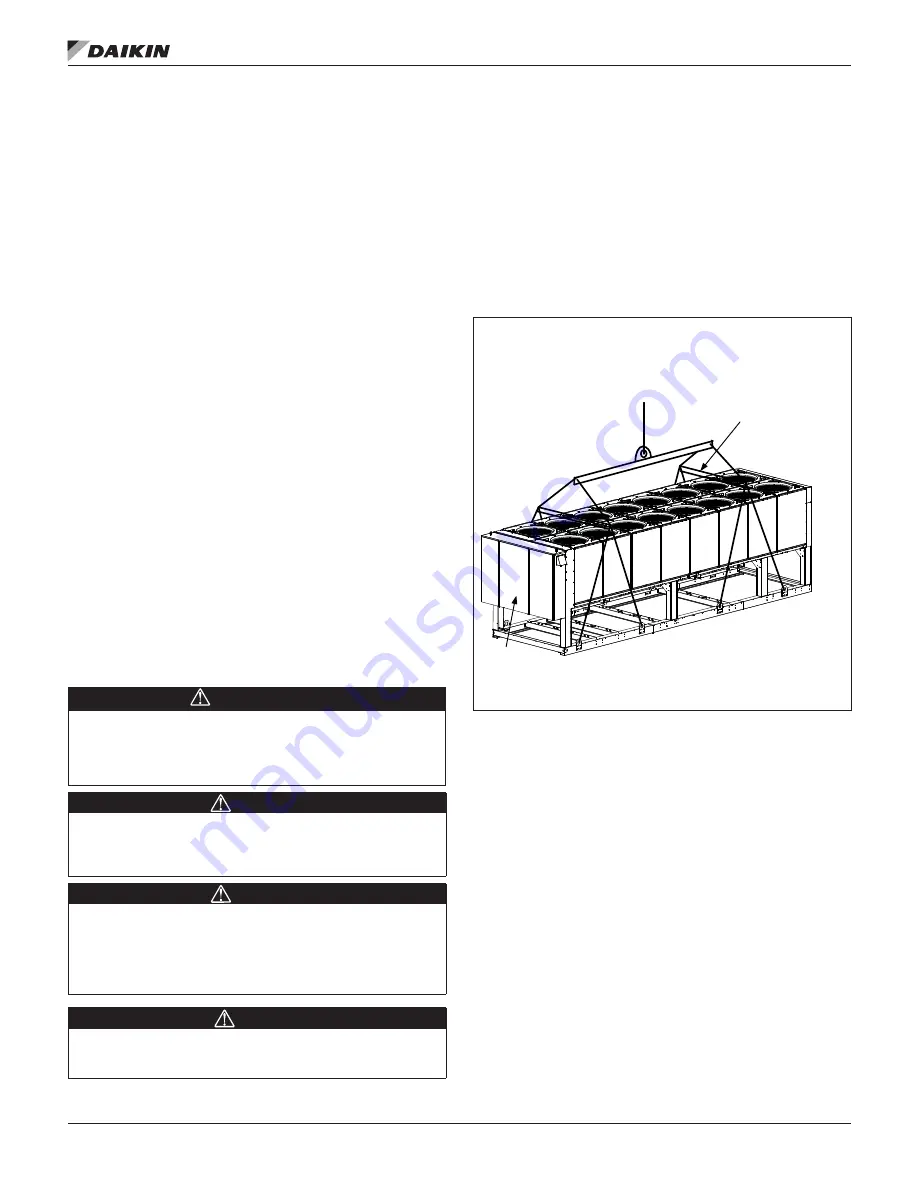

To lift an AWV unit with the Integrated Waterside Economizer

(IWSE) option, tabs with(1) or (2) 3” (76 mm) diameter holes

are provided on the lifting bars extending from the base of the

unit. For double hole lifting lugs, the left lifting holes must be

used when lifting the unit. Spreader bars and cables should

be arranged according to the rigging label provided on the

control panel to prevent damage to the unit. (see

for an example). Lifting bar extensions from the base may be

removed once the unit is in place.

NUMBER OF FANS MAY

VARY FROM THIS DIAGRAM

BUT LIFTING METHOD

REMAINS THE SAME.

ALL PROVIDED RIGGING HOLES

MUST BE USED. LIFT ONLY FROM

CONTROL

PANEL

SPREADER BARS MUST BE

USED TO PREVENT CABINET

DAMAGE. LOCATE BARS

ABOVE UNIT TO CLEAR FAN

GRILLES. MINIMUM DISTANCE

ACROSS UNIT BETWEEN

CABLE OR CHAINS IS

90 INCHES.

BASE POINTS AS SHOWN.

L1

L2

OPPOSITE

SIDE

L3

L4

OPPOSITE

SIDE

L5

L6

OPPOSITE

SIDE

L7

L8

OPPOSITE

SIDE - (NOT ON

NOT SHOWN FOR DRAWING SIMPLICITY.

COMPRESSORS, EVAPORATOR, AND PIPING

REPRESENTATIVE LIFTING SCHEMATIC -

ALL MODELS)