Installation Manual

EDUS04-906

30

Room Air Conditioners H-Series

11

Refri

g

erant Pipin

g

Work

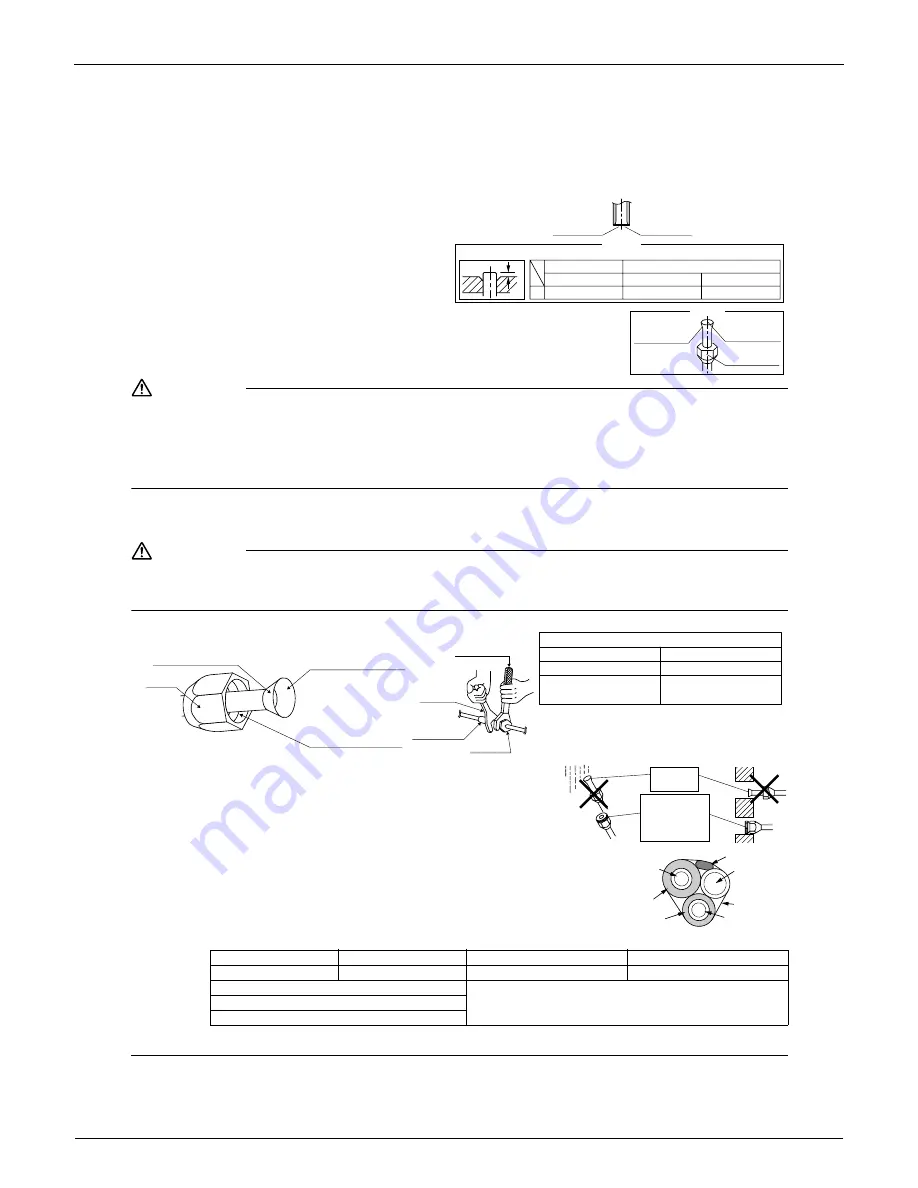

1.

Flarin

g

the pipe end.

1) C

u

t the pipe end

w

ith a pipe c

u

tter.

2) Remo

v

e

bu

rrs

w

ith the c

u

t s

u

rface facing do

w

n

w

ard

so that the chips do not enter the pipe.

3) P

u

t the flare n

u

t on the pipe.

4) Flare the pipe.

5) Check that the flaring is properly made.

WARNING

1) Do not

u

se mineral oil on flared part.

2) Pre

v

ent mineral oil from getting into the system as this

w

o

u

ld red

u

ce the lifetime of the

u

nits.

3)

N

e

v

er

u

se piping

w

hich has

b

een

u

sed for pre

v

io

u

s installations. Only

u

se par ts

w

hich are deli

v

ered

w

ith the

u

nit.

4) Do ne

v

er install a drier to this R410A

u

nit in order to g

u

arantee its lifetime.

5) The drying material may dissol

v

e and damage the system.

6) Incomplete flaring may ca

u

se refrigerant gas leakage.

2.

Refri

g

erant pipin

g

.

CAUTION

1) Use the flare n

u

t fixed to the main

u

nit t o pre

v

ent aging and deterioration.

2) To pre

v

ent gas leakage, apply refrigeration oil only to the inner s

u

rface of the flare. (Use refrigeration oil for R410A.)

3) Use tor

qu

e

w

renches

w

hen tightening the flare n

u

ts to pre

v

ent damage to the flare n

u

ts and gas leakage.

Align the centers of

b

oth flares and tighten the flare n

u

ts 3 or 4 t

u

rns

b

y hand. Then tighten them f

u

lly

w

ith the tor

qu

e

w

renches.

2-1. Caution on pipin

g

handlin

g

.

1) Protect the open end of the pipe against d

u

st and moist

u

re.

2) All pipe

b

ends sho

u

ld

b

e as gentle as possi

b

le. Use a pipe

b

ender for

b

ending.

2-2. Selection of copper and heat insulation materials.

•

W

hen

u

sing commercial copper pipes and fittings, o

b

ser

v

e the follo

w

ing:

1) Ins

u

lation material: Polyethylene foam

Heat transfer rate: 0.041 to 0.052

W

/mK (0.024 to 0.030 Bt

u

/fth°F (0.035 to 0.045 kcal/mh°C))

Choose heat ins

u

lation materials that are designed for H

V

AC

u

se.

2) Be s

u

re to ins

u

late

b

oth the gas and li

qu

id piping and to pro

v

ide ins

u

lation dimensions as

b

elo

w

.

3) Use separate thermal ins

u

lation pipes for gas and li

qu

id refrigerant pipes.

Gas side

Li

qu

id side

Gas pipe thermal ins

u

lation

Li

qu

id pipe thermal ins

u

lation

O.D. 3/

8

inch (9.5mm)

O.D. 1/4 inch (6.4mm)

I.D. 0.472-0.590 inch (12-15mm)

I.D. 0.315-0.393 inch (

8

-10mm)

Minim

u

m

b

end radi

u

s

Thickness 0.393 inch (10mm) Min.

1-3/16 inch (30mm) or more

Thickness 0.031 inch (0.

8

mm) (C1220T-O)

Set exactly at the position sho

w

n

b

elo

w

.

A

Flaring

Die

A

0-0.020 inch (0-0.5mm)

Cl

u

tch-type

Flare tool for R410A

0.039-0.059 inch (1.0-1.5mm)

Cl

u

tch-type (Rigid-type)

0.059-0.079 inch (1.5-2.0mm)

W

ing-n

u

t type (Imperial-type)

Con

v

entional flare tool

(C

u

t exactly at

right angles.)

Remo

v

e

bu

rrs

Check

Flare’s inner

s

u

rface m

u

st

b

e fla

w

-free.

The pipe end m

u

st

b

e e

v

enly flared in

a perfect circle.

Make s

u

re that the

flare n

u

t is fitted.

24.1-29.4 ft·l

b

f

(32.7-39.9

N

·m)

10.4-12.7 ft·l

b

f

(14.2-17.2

N

·m)

Flare n

u

t tightening tor

qu

e

Gas side

Li

qu

id side

3/

8

inch (9.5mm)

1/4 inch (6.4mm)

Do not apply refrigeration

oil to the o

u

ter s

u

rface.

Flare n

u

t

Apply refrigeration oil to the

inner s

u

rface of the flare.

Do not apply refrigeration

oil to the flare n

u

t a

v

oid

tightening

w

ith o

v

er tor

qu

e.

[Apply oil]

Tor

qu

e

w

rench

Piping

u

nion

Flare n

u

t

Spanner

[Tighten]

W

all

If no flare cap is

a

v

aila

b

le, co

v

er

the flare mo

u

th

w

ith tape to keep

dirt or

w

ater o

u

t.

Be s

u

re to

place a cap.

Rain

Ins

u

lation tape

Li

qu

id pipe ins

u

lation

Inter-

u

nit

w

iring

Gas pipe ins

u

lation

Gas pipe

Drain hose

Li

qu

id pipe

Summary of Contents for Quaternity FTXG09HVJU

Page 1: ...EDUS04 906_a H Series Heat Pump...

Page 44: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 43 Ground terminal...

Page 45: ...Operation Manual EDUS04 906 44 Room Air Conditioners H Series DRY button...

Page 46: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 45...

Page 47: ...Operation Manual EDUS04 906 46 Room Air Conditioners H Series...

Page 48: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 47...

Page 50: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 49...

Page 51: ...Operation Manual EDUS04 906 50 Room Air Conditioners H Series...

Page 52: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 51...

Page 55: ...Operation Manual EDUS04 906 54 Room Air Conditioners H Series...

Page 56: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 55 1 8 F 1 C 3 6 F 2 C...

Page 57: ...Operation Manual EDUS04 906 56 Room Air Conditioners H Series...

Page 58: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 57 COOLING or DRY COOLING mode or...

Page 59: ...Operation Manual EDUS04 906 58 Room Air Conditioners H Series...

Page 60: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 59...

Page 61: ...Operation Manual EDUS04 906 60 Room Air Conditioners H Series...

Page 62: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 61...

Page 63: ...Operation Manual EDUS04 906 62 Room Air Conditioners H Series...

Page 64: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 63...

Page 65: ...Operation Manual EDUS04 906 64 Room Air Conditioners H Series...

Page 66: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 65...

Page 67: ...Operation Manual EDUS04 906 66 Room Air Conditioners H Series...

Page 68: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 67...

Page 69: ...Operation Manual EDUS04 906 68 Room Air Conditioners H Series...

Page 70: ...EDUS04 906 Operation Manual Room Air Conditioners H Series 69 3P226009 1...

Page 79: ...Optional Accessories EDUS04 906 78 Room Air Conditioners H Series...