Optional Accessories

EDUS04-906_b

76

Room Air Conditioners H-Series

13.2.2 KRP928B2S

Safety Precautions

Read these Safety Precautions carefully to ensure correct installation.

This manual classifies precautions into WARNING and CAUTION.

WARNING :

Failure to follow WARNING is very likely to result in such grave

consequences as death or serious injury.

CAUTION :

Failure to follow CAUTION may result in serious injury or

property damage, and in certain circumstances, may result in

a grave consequence.

Be sure to follow all the precautions below ; they are all important for

ensuring safety.

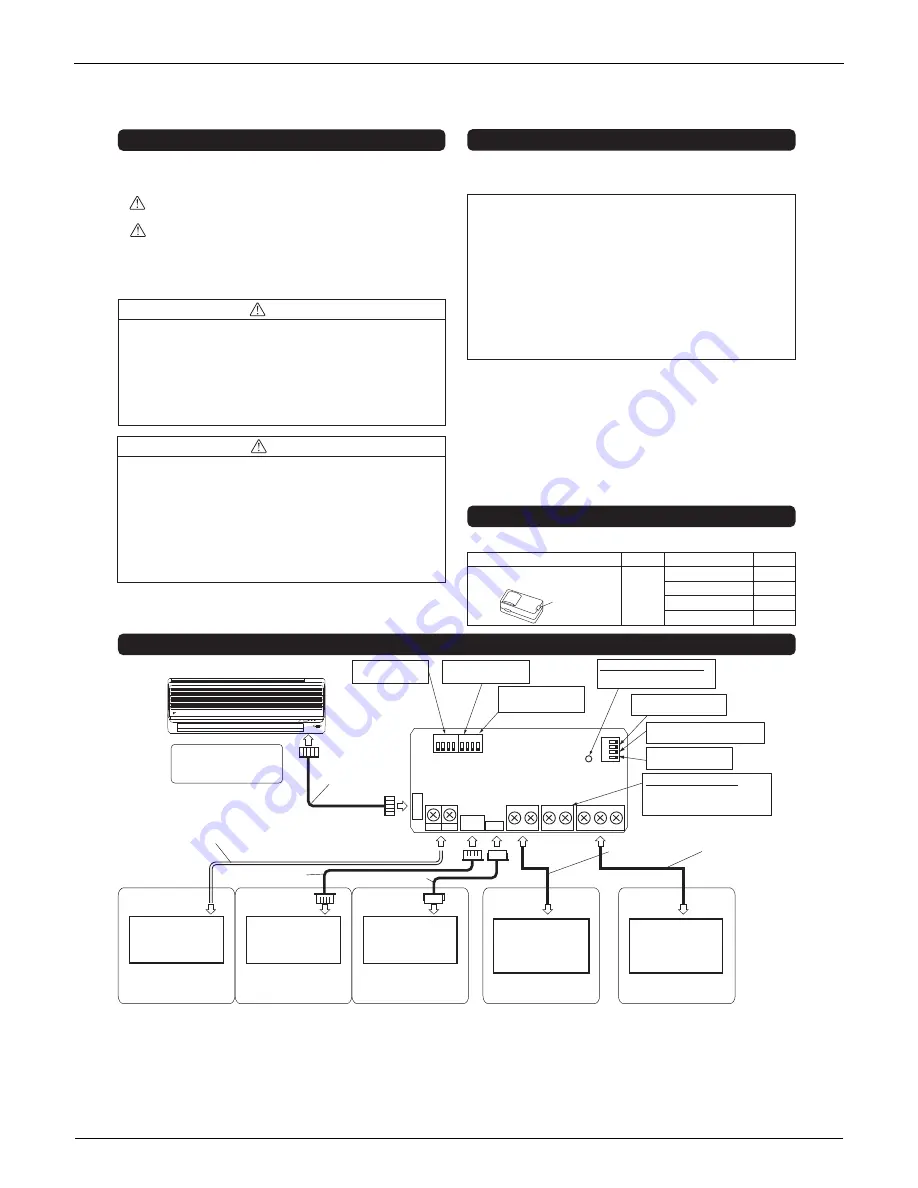

3.Names of Parts and Electric Wiring

WARNING

CAUTION

After installation is complete, test the operation of the PCB set to check

for problems, and explain how to use the set to the end-user.

1.Overview, Features and Compatible Models

This kit is the interface required when connecting the central controller and a Daikin Room Air

Conditioner. Use of the central controller makes it possible to perform the following monitoring

and operations. It is compatible with room air conditioners which have an HA connector S21.

Precaution

1.When reading the Operating / error signals, a separate external power source

(DC 12V) is needed.

2.A separate timer power source (DC 16V) is needed when using the schedule

timer independently, and not in conjunction with other central controllers.

3.The range of temperatures that can be set from the central controller is 18

°

C to

32

°

C in cooling and 14

°

C to 28

°

C in heating.

4.Fan operation cannot be selected from the central controller or wired remote controller.

5.Group control (i.e., control of multiple indoor units with a single remote controller) is

not available.

6.Monitoring is not available of the thermo status, compressor operating status,

indoor fan operating status, electric heater, or humidifier operating status.

7.Forced thermo off, filter sign display and reset, fan direction and speed settings,

air conditioning fee management, energy savings instructions, low-noise

instructions, and demand instructions cannot be made.

1.Run / stop for the central controller and wired remote controller, operating mode

selection, and temperature can be set.

2.The operating status, any errors, and the content of those errors can be monitored

from the central controller and wired remote controller.

3.Run / stop for the central controller and wireless remote controller, operating mode

selection, and the temperature setting can be limited by the central controller.

4.Zone control can be performed from the central controller.

5.The unit can remember the operating status of the air conditioner before a power

outage and then start operating in the same status when the power comes back

on.

6.Card keys, operating control panels, and other constant / instantaneous

connection-compatible equipment can be connected.

7.The Operating / error signals can be read.

8.HA JEM-A-compatible equipment can be connected.

9.The indoor temperature can be monitored from the Ve-up controller.

2.Component Parts and Separately-Sold Parts which are Required

This kit includes the following components. Check to ensure that none of

these are missing.

1 2 3 4

1 2 3 4

1234

1

0

ON

OFF

ON

OFF

SW1

S16

S19

S6

F1

SW2

SW3

LED1

Tes1

S1

S8

S5

F2

Once the switches are set and

the wiring complete, secure the

case using the included

screws.

A cable field supply

A cable field supply

In case that the device coping

with HA JEM-A is connected

Connecting a Wired

Remote Controller

In case that a central remote

controller is connected

Connecting a Momentary / constant

Contact Input Equipment

Reading the Operating / error Display

Tele-con (Field supply)

Remote controller

BRC944

Series

Card key

(Field supply)

Operating control panel

(Field supply)

KRC65, KRC72,

KDC100A10, and KDC101B

Series cannot be connected.

The adapter included with the

remote controller is not used.

DAIKIN

<Wiring procedure>

Supplied connection harness

Installation should be left to the dealer or another qualified professional.

Improper installation by yourself may cause malfunction, electrical shock, or fire.

Install the set according to the instructions given in this manual.

Incomplete or improper installation may cause malfunction, electrical shock, or fire.

Be sure to use the standard attachments or the genuine parts.

Use of other parts may cause malfunction, electrical shock, or fire.

Disconnect power to the connected equipment before starting installation.

Failure to do so may cause malfunction, electrical shock, or fire.

An earth leakage circuit breaker should be installed.

If the breaker is not installed, electrical shock may occur.

Do not install the set in a location where there is danger of exposure to

inflammable gas.

Gas accumulated around the unit at the worst may cause fire.

To prevent damage due to electrostatic discharge, touch your hand to a

nearby metal object (doorknob, aluminum sash, etc.) to discharge static

electricity from your body before touching this kit.

Static electricity can damage this kit.

Lay this cable separately from other power cables to avoid external

electrical noises.

Screw cover

Non polarity

Included in the Drain

Up Kit.

Separately sold remote control code (quadplex)

KRCW101A Series

Operating monitoring

equipment

(Field supply)

Parts

Kit assy

PCB is in the housing.

Q’ty

Q’ty

1

Parts

Connection harness (about 1.6m)

Mounting screws

Binding band

Installation manual

1

set

3

pcs.

1

pc.

1

set

Room air conditioner indoor unit

To HA connector (S21)

Cable available field supply

(See the installation manual of

the central remote controller)

Lower group number

switch (SW1)

Upper group number

switch (SW2-1to 3)

Operation when recovering

from a power outage

mode

switch (SW2-4)

Service monitor (LED1: green)

When the CPU is working

properly, the LED flashes.

Power supply terminal (S8)

Connect an external DC 12V power

supply only when reading the

Operating / error display.

Japanese unit / Overseas unit

Setting switch (SW3-3)

Momentary contact / constant contact

Selection switch (SW3-2)

Forced stop

Settings switch (SW3-1)

Central controller equipment

DCS302

Series

DCS301

Series

DCS601

Series

DST301

Series

Summary of Contents for Quaternity H-Series

Page 1: ...EDUS04 906_b H Series Heat Pump...

Page 45: ...Operation Manual EDUS04 906_b 44 Room Air Conditioners H Series Ground terminal...

Page 46: ...EDUS04 906_b Operation Manual Room Air Conditioners H Series 45 DRY button...

Page 47: ...Operation Manual EDUS04 906_b 46 Room Air Conditioners H Series...

Page 48: ...EDUS04 906_b Operation Manual Room Air Conditioners H Series 47...

Page 49: ...Operation Manual EDUS04 906_b 48 Room Air Conditioners H Series...

Page 51: ...Operation Manual EDUS04 906_b 50 Room Air Conditioners H Series...

Page 52: ...EDUS04 906_b Operation Manual Room Air Conditioners H Series 51...

Page 53: ...Operation Manual EDUS04 906_b 52 Room Air Conditioners H Series...

Page 56: ...EDUS04 906_b Operation Manual Room Air Conditioners H Series 55...

Page 57: ...Operation Manual EDUS04 906_b 56 Room Air Conditioners H Series 1 8 F 1 C 3 6 F 2 C...

Page 58: ...EDUS04 906_b Operation Manual Room Air Conditioners H Series 57...

Page 59: ...Operation Manual EDUS04 906_b 58 Room Air Conditioners H Series COOLING or DRY COOLING mode or...

Page 60: ...EDUS04 906_b Operation Manual Room Air Conditioners H Series 59...

Page 61: ...Operation Manual EDUS04 906_b 60 Room Air Conditioners H Series...

Page 62: ...EDUS04 906_b Operation Manual Room Air Conditioners H Series 61...

Page 63: ...Operation Manual EDUS04 906_b 62 Room Air Conditioners H Series...

Page 64: ...EDUS04 906_b Operation Manual Room Air Conditioners H Series 63...

Page 65: ...Operation Manual EDUS04 906_b 64 Room Air Conditioners H Series...

Page 66: ...EDUS04 906_b Operation Manual Room Air Conditioners H Series 65...

Page 67: ...Operation Manual EDUS04 906_b 66 Room Air Conditioners H Series...

Page 68: ...EDUS04 906_b Operation Manual Room Air Conditioners H Series 67...

Page 69: ...Operation Manual EDUS04 906_b 68 Room Air Conditioners H Series...

Page 70: ...EDUS04 906_b Operation Manual Room Air Conditioners H Series 69...

Page 71: ...Operation Manual EDUS04 906_b 70 Room Air Conditioners H Series 3P226009 1...