SiUS371901E

Field Settings for Indoor Unit

Field Settings and Test Operation

174

CXTQ-TA

∗

1. The second code No. 07 is used for disabling the starting of gas furnace interlocking with room temperature.

z

: Available

— : Not available

Setting the Airflow Rate when Heating

The fan revolution is changed to maintain the sufficient distance for warm air to reach during the heating

operation. The setting should be changed depending on the installation condition of the unit.

Note that this setting is effective only during the heating operation.

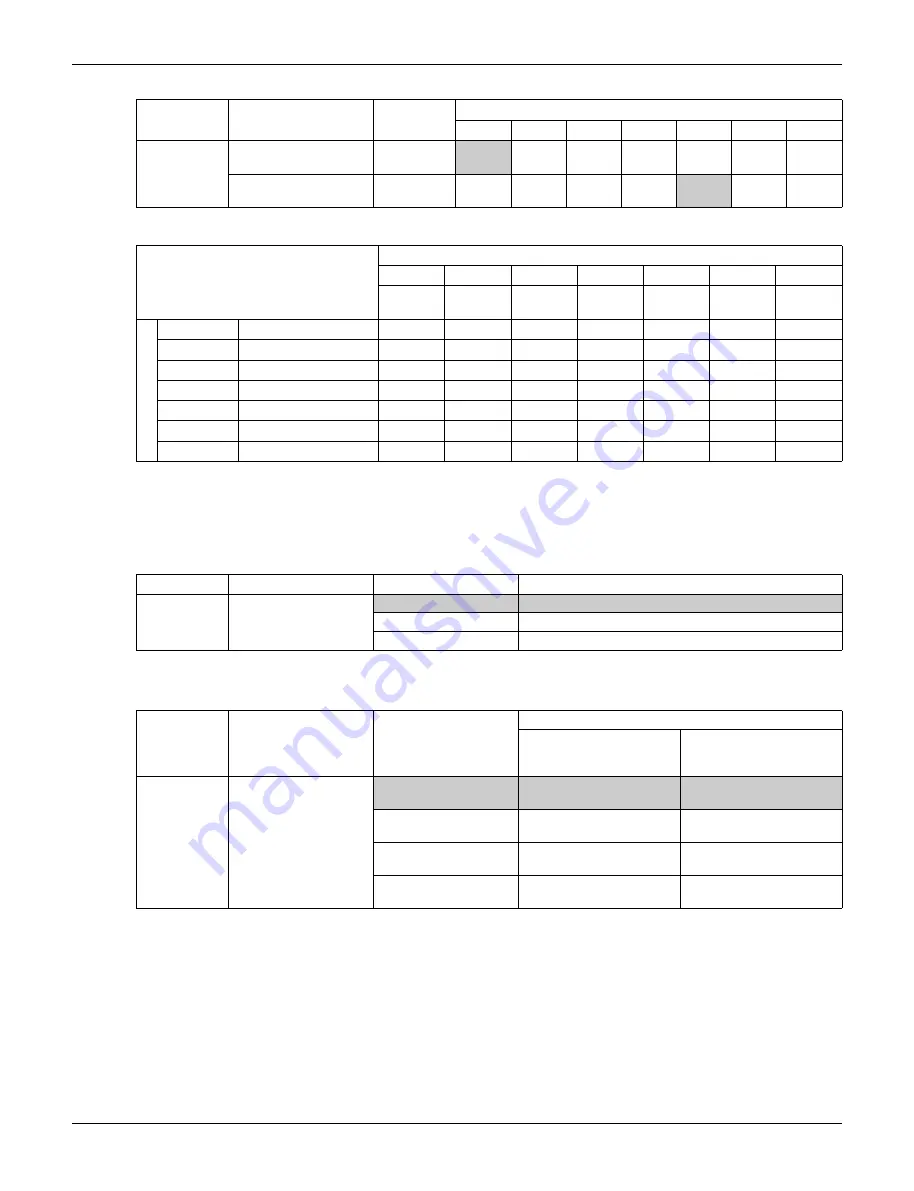

Electric Heater Setting (for FXTQ-TA models)

Mode No.

First Code No.

Symbol

Second Code No.

01

02

03

04

05

06

07 (

∗

1)

11 (21)

1

Ton

–4°C

(–7.2°F)

–3.5°C

(–6.3°F)

–3°C

(–5.4°F)

–2.5°C

(–4.5°F)

–2°C

(–3.6°F)

–1.5°C

(–2.7°F)

–100°C

(–148°F)

2

Toff

–2°C

(–3.6°F)

–1.5°C

(–2.7°F)

–1°C

(–1.8°F)

–0.5°C

(–0.9°F)

0°C

(0°F)

0.5°C

(0.9°F)

–98°C

(–144.4°F)

Second Code No.

Ton

01

02

03

04

05

06

07

–4°C

(–7.2°F)

–3.5°C

(–6.3°F)

–3°C

(–5.4°F)

–2.5°C

(–4.5°F)

–2°C

(–3.6°F)

–1.5°C

(–2.7°F)

–100°C

(–148°F)

Toff

07

–98°C (–144.4°F)

—

—

—

—

—

—

z

06

0.5°C (0.9°F)

z

z

z

z

z

z

z

05

0°C (0°F)

z

z

z

z

z

—

z

04

–0.5°C (–0.9°F)

z

z

z

z

—

—

z

03

–1°C (–1.8°F)

z

z

z

—

—

—

z

02

–1.5°C (–2.7°F)

z

z

—

—

—

—

z

01

–2°C (–3.6°F)

z

—

—

—

—

—

z

Mode No.

First Code No.

Second Code No.

Contents

11 (21)

3

01

Standard

02

Slightly increased

03

Increased

Mode No.

First Code No.

Second Code No.

Contents

Heater operation

Electric heater run for

defrost/oil return

operation

11 (21)

3

01

Electric heater with heat

pump not allowed

Not allowed

02

Electric heater with heat

pump allowed

Not allowed

07

Electric heater with heat

pump not allowed

Allowed

08

Electric heater with heat

pump allowed

Allowed

Summary of Contents for REYQ-XA

Page 1: ...Service Manual SiUS371901E REYQ72 456XATJU REYQ72 456XAYDU REYQ72 432XAYCU Heat Recovery 60 Hz...

Page 415: ...SiUS371901E Wiring Diagrams Appendix 402 REYQ144 168XATJU 2D119206A...

Page 416: ...Wiring Diagrams SiUS371901E 403 Appendix REYQ72 96 120XAYDU 2D119207B...

Page 417: ...SiUS371901E Wiring Diagrams Appendix 404 REYQ144 168XAYDU 2D119208B...

Page 418: ...Wiring Diagrams SiUS371901E 405 Appendix REYQ72 96 120 144 168XAYCU 2D119209A...

Page 421: ...SiUS371901E Wiring Diagrams Appendix 408 FXZQ05 07 09 12 15 18TAVJU 3D110443A...

Page 423: ...SiUS371901E Wiring Diagrams Appendix 410 FXEQ07 09 12 15 18 24PVJU 3D098557A...

Page 425: ...SiUS371901E Wiring Diagrams Appendix 412 FXSQ05 07 09 12 15 18 24 30 36 48 54TAVJU C 3D110467C...

Page 426: ...Wiring Diagrams SiUS371901E 413 Appendix FXMQ07 09 12 15 18 24 30 36 48 54PBVJU 3D093209B...

Page 428: ...Wiring Diagrams SiUS371901E 415 Appendix FXHQ12 24 36MVJU 3D048116C...

Page 429: ...SiUS371901E Wiring Diagrams Appendix 416 FXAQ07 09 12 18 24PVJU C 3D075354D...

Page 435: ...SiUS371901E Wiring Diagrams Appendix 422 VAM1200GVJU 3D073270D...

Page 437: ...SiUS371901E Wiring Diagrams Appendix 424 1 4 2 Multi Branch Selector Unit BS4Q54TVJ 3D089123B...

Page 438: ...Wiring Diagrams SiUS371901E 425 Appendix BS6 8Q54TVJ 2D089122B...

Page 439: ...SiUS371901E Wiring Diagrams Appendix 426 BS10 12Q54TVJ 2D089121B...

Page 440: ...Revision History Month Year Version Revised contents 04 2019 SiUS371901E First edition...