SiUS371901E

Field Settings for Indoor Unit

Field Settings and Test Operation

180

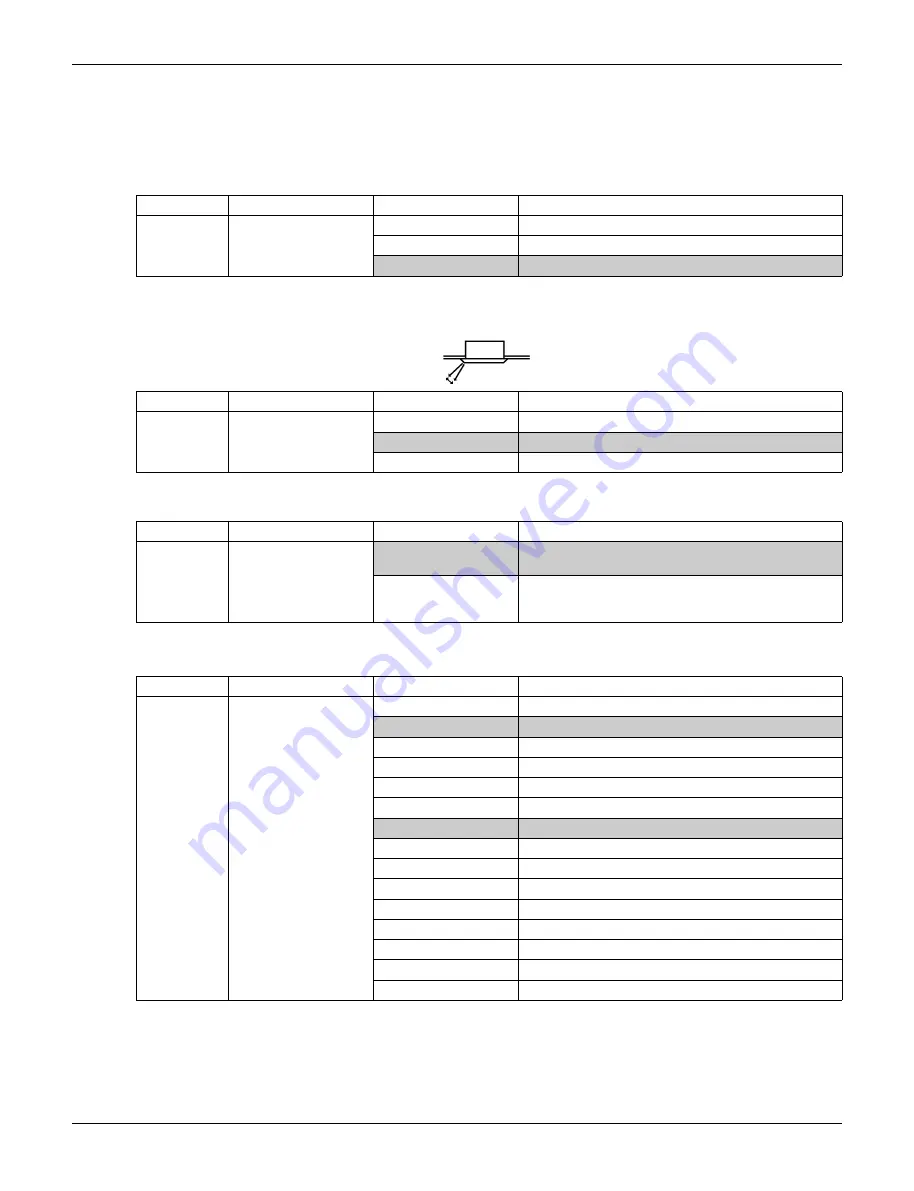

Swing Pattern Settings

(For units with the infrared presence/floor sensor only)

Set the flap operation in swing mode.

With the factory swing, flaps facing each other are synchronized to operate, and flaps placed side by side are set

to swing in an opposite direction to agitate airflow to reduce temperature irregularity.

Conventional swing operation (all direction synchronized swing) can be set onsite.

Setting of Airflow Direction Adjustment Range

Make the following airflow direction setting according to the respective purpose.

∗

Some indoor unit models are not equipped with draft prevention (upward) function.

Setting of Static Pressure Selection (for FXDQ-M models)

External Static Pressure Settings

FXMQ-PB models

The Second Code No. is set to

02

for FXMQ07/09/12PB, and

07

for FXMQ15/18/24/30/36/48/54PB at factory

setting.

∗

1. FXMQ15/18/24/30/36/48PB cannot be set to 30 Pa (0.12 inWG).

∗

2. FXMQ07/09/12PB cannot be set to 110-200 Pa (0.44-0.80 inWG).

∗

3. FXMQ54PB cannot be set to 30 Pa (0.12 inWG) or 150-200 Pa (0.60-0.80 inWG).

Mode No.

First Code No.

Second Code No.

Contents

13 (23)

2

01

All direction synchronized swing

02

—

03

Facing swing

Mode No.

First Code No.

Second Code No.

Contents

13 (23)

4

01

Upward (Draft prevention)

02

Standard

03

Downward (Ceiling soiling prevention)

Model No.

First Code No.

Second Code No.

Contents

13 (23)

5

01

Standard (FXDQ07-12M: 10 Pa (0.04 inWG),

FXDQ18/24M: 30 Pa (0.12 inWG))

02

High static pressure

(FXDQ07-12M: 15 Pa (0.06 inWG),

FXDQ18/24M: 45 Pa (0.18 inWG))

Mode No.

First Code No.

Second Code No.

Contents

13 (23)

6

01

30 Pa (0.12 inWG) (

∗

1) (

∗

3)

02

50 Pa (0.20 inWG)

03

60 Pa (0.24 inWG)

04

70 Pa (0.28 inWG)

05

80 Pa (0.32 inWG)

06

90 Pa (0.36 inWG)

07

100 Pa (0.40 inWG)

08

110 Pa (0.44 inWG) (

∗

2)

09

120 Pa (0.48 inWG) (

∗

2)

10

130 Pa (0.52 inWG) (

∗

2)

11

140 Pa (0.56 inWG) (

∗

2)

12

150 Pa (0.60 inWG) (

∗

2) (

∗

3)

13

160 Pa (0.64 inWG) (

∗

2) (

∗

3)

14

180 Pa (0.72 inWG) (

∗

2) (

∗

3)

15

200 Pa (0.80 inWG) (

∗

2) (

∗

3)

Summary of Contents for REYQ72-456XATJU

Page 415: ...SiUS371901E Wiring Diagrams Appendix 402 REYQ144 168XATJU 2D119206A ...

Page 416: ...Wiring Diagrams SiUS371901E 403 Appendix REYQ72 96 120XAYDU 2D119207B ...

Page 417: ...SiUS371901E Wiring Diagrams Appendix 404 REYQ144 168XAYDU 2D119208B ...

Page 418: ...Wiring Diagrams SiUS371901E 405 Appendix REYQ72 96 120 144 168XAYCU 2D119209A ...

Page 421: ...SiUS371901E Wiring Diagrams Appendix 408 FXZQ05 07 09 12 15 18TAVJU 3D110443A ...

Page 423: ...SiUS371901E Wiring Diagrams Appendix 410 FXEQ07 09 12 15 18 24PVJU 3D098557A ...

Page 426: ...Wiring Diagrams SiUS371901E 413 Appendix FXMQ07 09 12 15 18 24 30 36 48 54PBVJU 3D093209B ...

Page 428: ...Wiring Diagrams SiUS371901E 415 Appendix FXHQ12 24 36MVJU 3D048116C ...

Page 429: ...SiUS371901E Wiring Diagrams Appendix 416 FXAQ07 09 12 18 24PVJU C 3D075354D ...

Page 435: ...SiUS371901E Wiring Diagrams Appendix 422 VAM1200GVJU 3D073270D ...

Page 437: ...SiUS371901E Wiring Diagrams Appendix 424 1 4 2 Multi Branch Selector Unit BS4Q54TVJ 3D089123B ...

Page 438: ...Wiring Diagrams SiUS371901E 425 Appendix BS6 8Q54TVJ 2D089122B ...

Page 439: ...SiUS371901E Wiring Diagrams Appendix 426 BS10 12Q54TVJ 2D089121B ...

Page 440: ...Revision History Month Year Version Revised contents 04 2019 SiUS371901E First edition ...