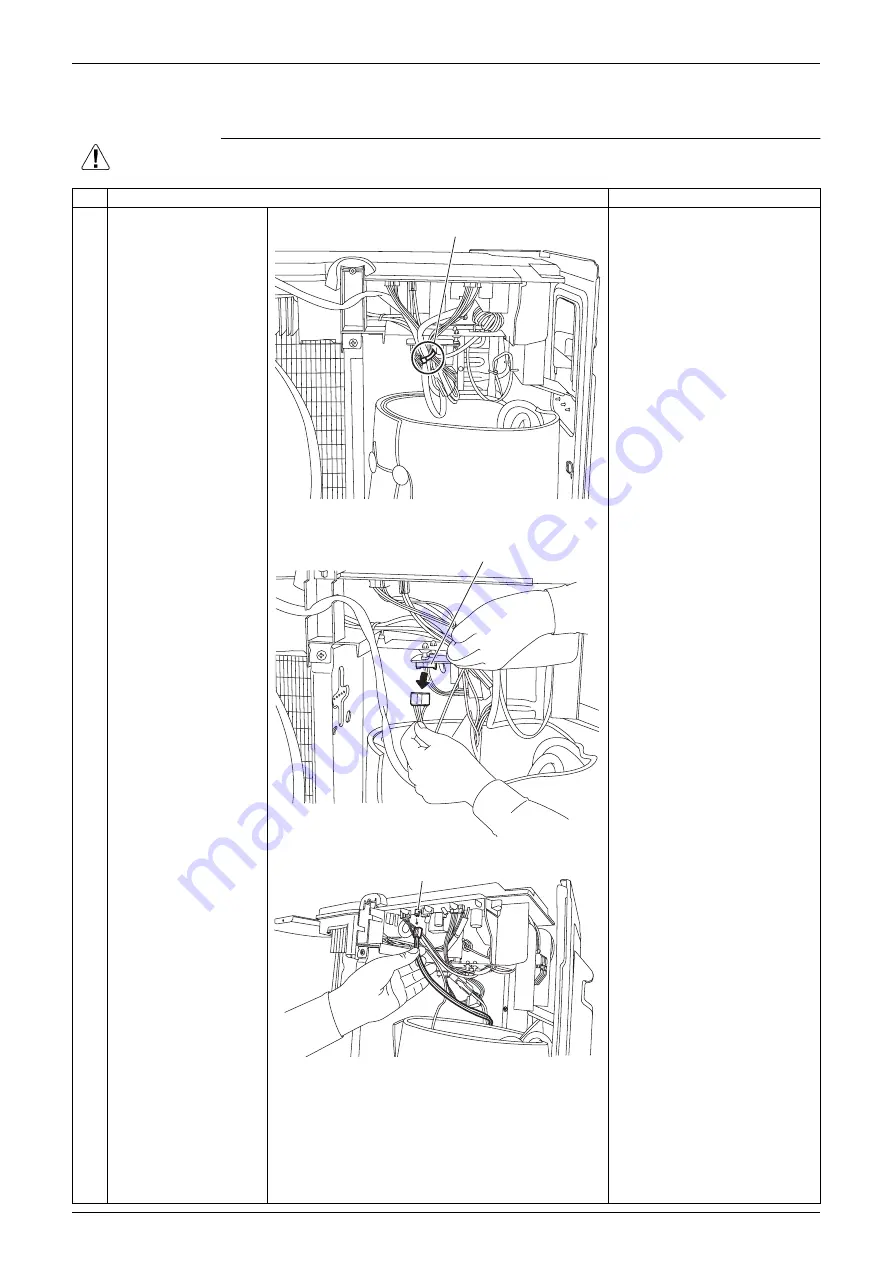

Si001406EB

Electrical Box

Removal Procedure

7

3. Electrical Box

Warning

Be sure to wait for 10 minutes or more after turning off all power supplies before

disassembling work.

Step

Procedure

Points

1

Cut the clamp.

2

Disconnect the

connector [S79].

[S79]: fan motor

3

Disconnect the

connector [S40].

[S40]: overload protector

Clamp

(R23685)

[S79]

(R20656)

[S40]

(R20228)