5 Installation

Installation and operation manual

13

RKXYQ5T7Y1B

VRV IV compressor unit for indoor installation

4P408443-1 – 2015.07

Stage 2: Manual charging

(= charging in the "Manual additional refrigerant charge" mode)

Summary – Manual charging

:

Refrigerant bottle

Connected to the service port for refrigerant

charge.

This charges to both circuits, and to the

compressor unit's internal refrigerant piping.

Stop valves

Open

Compressor

Operates

5

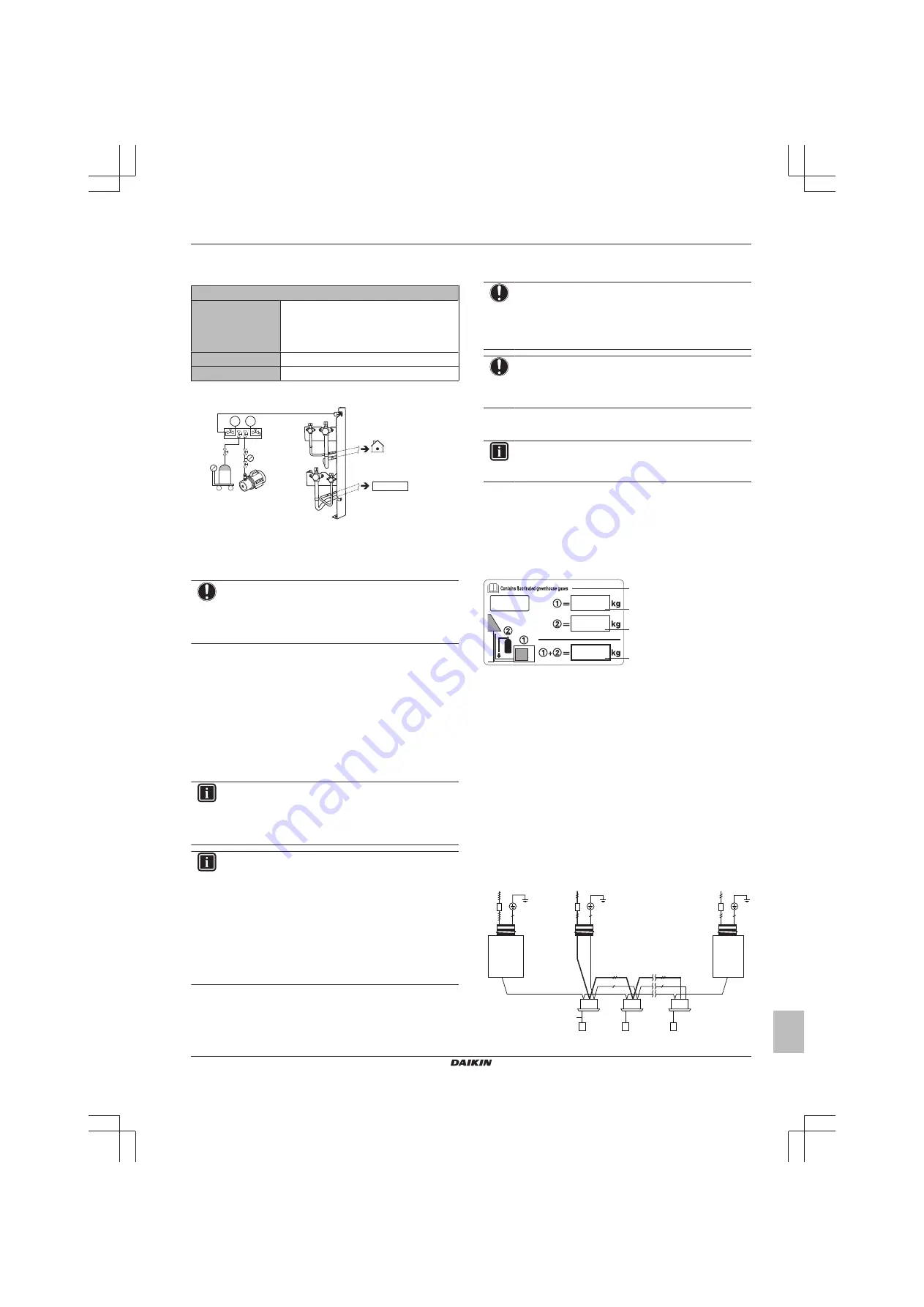

Connect as shown. Make sure valve A is closed.

p< p>

R410A

a

c

b

A

e

d

a

Weighing scales

b

Refrigerant R410A tank (siphon system)

c

Vacuum pump

d

Refrigerant charge port

e

Heat exchanger unit

A

Valve A

NOTICE

The refrigerant charging port is connected to the piping

inside the unit. The unit's internal piping is already factory

charged with refrigerant, so be careful when connecting

the charge hose.

6

Open all compressor unit stop valves. At this point, valve A

must remain closed!

7

Take all the precautions mentioned in

into account.

8

Turn on the power of the indoor units, compressor unit and heat

exchanger unit.

9

Activate setting [2‑20] to start the manual additional refrigerant

charge mode. For details, see

"6.1.8 Mode 2: Field settings" on

.

Result:

The unit will start operation.

INFORMATION

The manual refrigerant charge operation will automatically

stop within 30 minutes. If charging is not completed after

30 minutes, perform the additional refrigerant charging

operation again.

INFORMATION

▪ When a malfunction is detected during the procedure

(e.g., in case of closed stop valve), a malfunction code

will be displayed. In that case, refer to

codes when charging refrigerant" on page 13

solve the malfunction accordingly. Resetting the

malfunction can be done by pushing BS3. You can

restart the "Charging" instructions.

▪ Aborting the manual refrigerant charge is possible by

pushing BS3. The unit will stop and return to idle

condition.

10

Open valve A.

11

Charge refrigerant until the remaining determined additional

refrigerant amount is added, and then close valve A.

12

Press BS3 to stop the manual additional refrigerant charge

mode.

NOTICE

Make sure to open all stop valves after (pre-) charging the

refrigerant.

Operating with the stop valves closed will damage the

compressor.

NOTICE

After adding the refrigerant, do not forget to close the lid of

the refrigerant charging port. The tightening torque for the

lid is 11.5 to 13.9 N•m.

5.6.4

Error codes when charging refrigerant

INFORMATION

If a malfunction occurs, the error code is displayed on the

user interface of the indoor unit.

If a malfunction occurs, close valve A immediately. Confirm the

malfunction code and take corresponding action,

problems based on error codes" on page 22

5.6.5

To fix the fluorinated greenhouse gases

label

1

Fill in the label as follows:

d

c

b

a

a

From the multilingual fluorinated greenhouse gases label

peal off the applicable language and stick it on top of

a

.

b

Factory refrigerant charge: see unit name plate

c

Additional refrigerant amount charged

d

Total refrigerant charge

2

Fix the label on the inside of the compressor unit. There is a

dedicated place for it on the wiring diagram label.

5.7

Connecting the electrical wiring

5.7.1

Field wiring: Overview

Field wiring consists of:

▪ Power supply (always including earth)

▪ Communication (= transmission) wiring between the compressor

unit, the heat exchanger unit, and the indoor units.

Example:

g

f

F1/F2

(16 V)

F1/F2

(16 V)

220-240 V

1~ 50 Hz

e

c

a

d

b

220-240 V

1~ 50 Hz

380-415 V

3N~ 50 Hz

a

Main switch