14 Troubleshooting

Installation and operation manual

30

RKXYQ5T7Y1B

VRV IV compressor unit for indoor installation

4P408443-1 – 2015.07

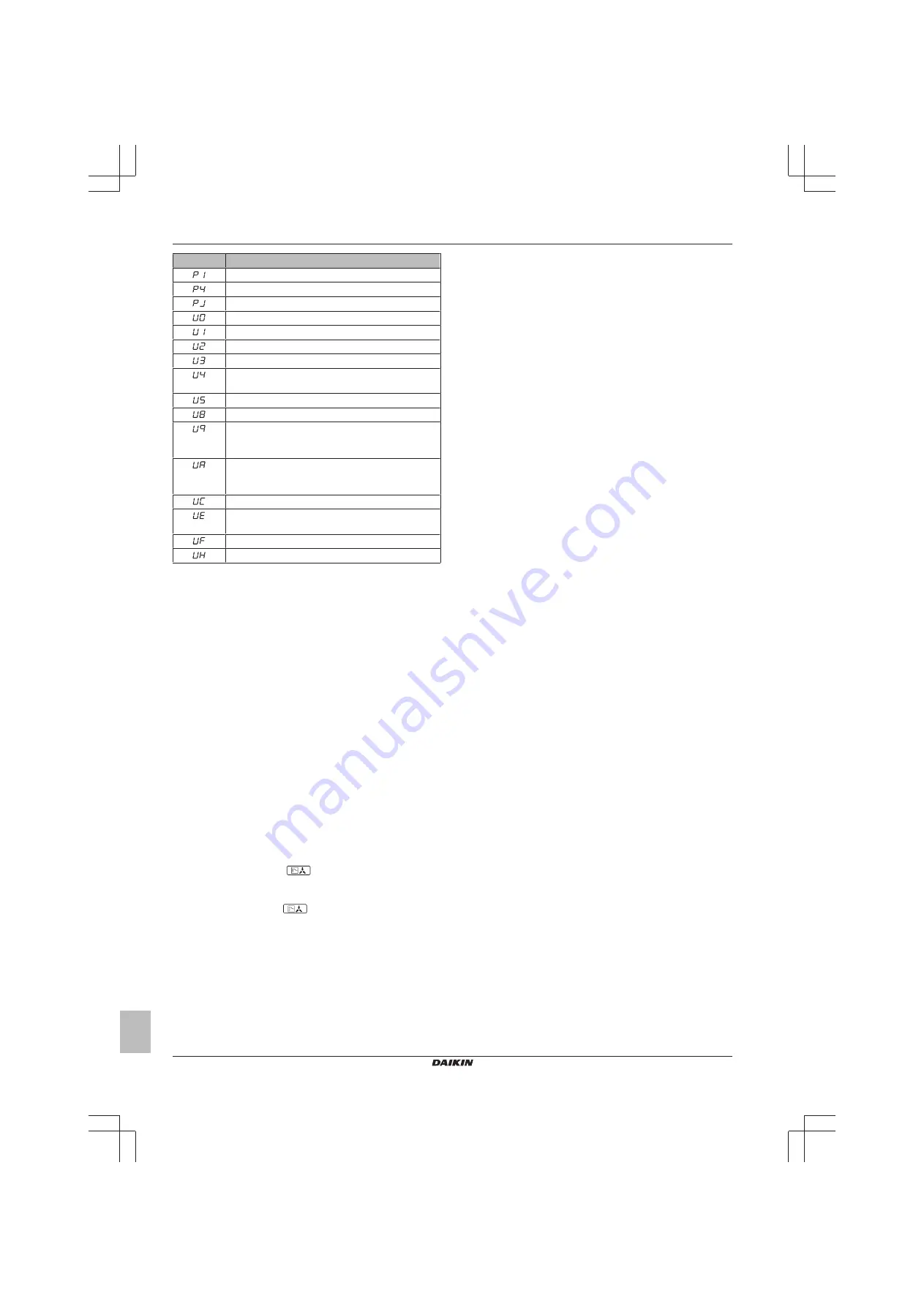

Main code

Contents

INV unbalanced power supply voltage

Fin thermistor malfunction

Heat exchanger unit capacity setting malfunction.

Abnormal low pressure drop, faulty expansion valve

Reversed power supply phase malfunction

INV voltage power shortage

System test run not yet executed

Faulty wiring indoor/heat exchanger unit/compressor

unit

Abnormal user interface - indoor communication

Abnormal main-sub user interface communication

System mismatch. Wrong type of indoor units

combined. Indoor unit malfunction. Heat exchanger

unit malfunction.

Connection malfunction over indoor units or type

mismatch (wrong type of indoor units or heat

exchanger unit)

Centralised address duplication

Malfunction in communication centralised control

device - indoor unit

Auto address malfunction (inconsistency)

Auto address malfunction (inconsistency)

14.2

Symptoms that are not air

conditioner troubles

Following symptoms are not air conditioner troubles:

14.2.1

Symptom: The system does not operate

▪ The air conditioner does not start immediately after the ON/OFF

button on the user interface is pressed. If the operation lamp

lights, the system is in normal condition. To prevent overloading of

the compressor motor, the air conditioner starts 5 minutes after it

is turned ON again in case it was turned OFF just before. The

same starting delay occurs after the operation mode selector

button was used.

▪ If "Under Centralized Control" is displayed on the user interface,

pressing the operation button causes the display to blink for a few

seconds. The blinking display indicates that the user interface

cannot be used.

▪ The system does not start immediately after the power supply is

turned on. Wait one minute until the micro computer is prepared

for operation.

14.2.2

Symptom: Cool/Heat cannot be changed

over

▪ When the display shows

(change-over under centralized

control), it shows that this is a slave user interface.

▪ When the cool/heat changeover remote control switch is installed

and the display shows

(change-over under centralized

control), this is because cool/heat changeover is controlled by the

cool/ heat changeover remote control switch. Ask your dealer

where the remote control switch is installed.

14.2.3

Symptom: Fan operation is possible, but

cooling and heating do not work

Immediately after the power is turned on. The micro computer is

getting ready to operate and is performing a communication check

with all indoor units. Please wait 12 minutes (max.) till this process is

finished.

14.2.4

Symptom: The fan strength does not

correspond to the setting

The fan speed does not change even if the fan speed adjustment

button in pressed. During heating operation, when the room

temperature reaches the set temperature, the compressor unit goes

off and the indoor unit changes to whisper fan speed. This is to

prevent cold air blowing directly on occupants of the room. The fan

speed will not change even when another indoor unit is in heating

operation, if the button is pressed.

14.2.5

Symptom: The fan direction does not

correspond to the setting

The fan direction does not correspond with the user interface

display. The fan direction does not swing. This is because the unit is

being controlled by the micro computer.

14.2.6

Symptom: White mist comes out of a unit

(Indoor unit)

▪ When humidity is high during cooling operation. If the interior of an

indoor unit is extremely contaminated, the temperature distribution

inside a room becomes uneven. It is necessary to clean the

interior of the indoor unit. Ask your dealer for details on cleaning

the unit. This operation requires a qualified service person.

▪ Immediately after the cooling operation stops and if the room

temperature and humidity are low. This is because warm

refrigerant gas flows back into the indoor unit and generates

steam.

14.2.7

Symptom: White mist comes out of a unit

(Indoor unit, heat exchanger unit)

When the system is changed over to heating operation after defrost

operation. Moisture generated by defrost becomes steam and is

exhausted.

14.2.8

Symptom: The user interface display

reads "U4" or "U5" and stops, but then

restarts after a few minutes

This is because the user interface is intercepting noise from electric

appliances other than the air conditioner. The noise prevents

communication between the units, causing them to stop. Operation

automatically restarts when the noise ceases.

14.2.9

Symptom: Noise of air conditioners

(Indoor unit, heat exchanger unit)

▪ A "zeen" sound is heard immediately after the power supply is

turned on. The electronic expansion valve inside an indoor unit

starts working and makes the noise. Its volume will reduce in

about one minute.

▪ A continuous low "shah" sound is heard when the system is in

cooling operation or at a stop. When the drain pump (optional

accessories) is in operation, this noise is heard.

▪ A "pishi-pishi" squeaking sound is heard when the system stops

after heating operation. Expansion and contraction of plastic parts

caused by temperature change make this noise.

▪ A low "sah", "choro-choro" sound is heard while the indoor unit is

stopped. When another indoor unit is in operation, this noise is

heard. In order to prevent oil and refrigerant from remaining in the

system, a small amount of refrigerant is kept flowing.