3 About the units and options

Installation and operation manual

5

RKXYQ5T7Y1B

VRV IV compressor unit for indoor installation

4P408443-1 – 2015.07

·

3

1

(10.1 N·m)

2

a

b

3

About the units and options

3.1

About the compressor unit and

heat exchanger unit

The compressor unit and heat exchanger unit are intended for indoor

installation and aimed for air to air heat pump applications.

Specification

RDXYQ5

Maximum capacity

Heating

16 kW

Cooling

14 kW

Outside ambient

design temperature

Heating

–20~15.5°C WB

Cooling

–5~46°C DB

Ambient design temperature of compressor

unit and heat exchanger unit

5~35°C DB

(26°C WB)

3.2

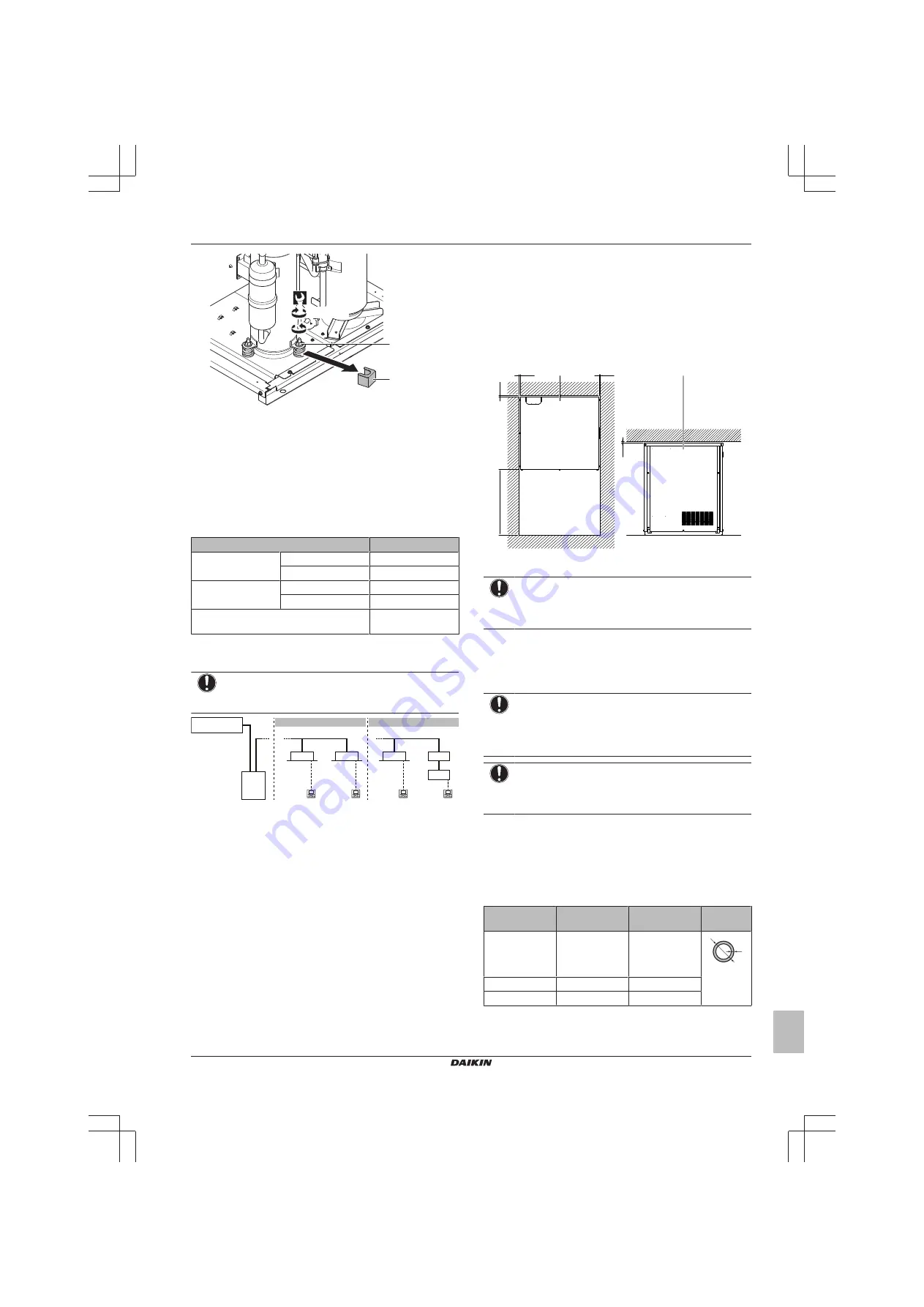

System layout

NOTICE

Design of the system must not be done at temperatures

below –15°C.

d

d

c

c

a

b

VRV DX

VRV DX

VRV DX

EKEXV

AHU

d

d

1

2

1

In case of VRV DX indoor units

2

In case of VRV DX indoor units combined with an air

handling unit

a

Heat exchanger unit

b

Compressor unit

c

Refrigerant piping

d

User interface (dedicated depending on indoor unit type)

VRV DX

VRV direct expansion (DX) indoor unit

EKEXV

Expansion valve kit

AHU

Air handling unit

4

Preparation

4.1

Preparing installation site

4.1.1

Installation site requirements of the

compressor unit

▪

Service space.

Mind the following requirements:

≥

10

a

≥

10

≥10

≥

500

≥

10

(mm)

3D098835-1

b

a

Top view

b

Front view

NOTICE

This is a class A product. In a domestic environment this

product may cause radio interference in which case the

user may be required to take adequate measures.

4.2

Preparing refrigerant piping

4.2.1

Refrigerant piping requirements

NOTICE

Refrigerant R410A requires strict cautions for keeping the

system clean and dry. Foreign materials (including mineral

oils or moisture) should be prevented from getting mixed

into the system.

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant. Use phosphoric acid deoxidised

seamless copper for refrigerant.

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30 mg/10 m.

4.2.2

Refrigerant piping material

▪

Piping material:

Phosphoric acid deoxidised seamless copper.

▪

Piping temper grade and thickness:

Outer diameter

(Ø)

Temper grade

Thickness (t)

(a)

6.4 mm (1/4")

9.5 mm (3/8")

12.7 mm (1/2")

Annealed (O)

≥0.80 mm

t

Ø

15.9 mm (5/8")

Annealed (O)

≥0.99 mm

19.1 mm (3/4")

Half hard (1/2H)

≥0.80 mm

(a)

Depending on the applicable legislation and the unit's

maximum working pressure (see "PS High" on the unit

name plate), larger piping thickness might be required.