12 Operation

Installation and operation manual

27

RKXYQ5T7Y1B

VRV IV compressor unit for indoor installation

4P408443-1 – 2015.07

To adjust

For programming temperature, fan speed and air flow direction refer

to the operation manual of the user interface.

12.3

Using the dry program

12.3.1

About the dry program

▪ The function of this program is to decrease the humidity in your

room with minimal temperature decrease (minimal room cooling).

▪ The micro computer automatically determines temperature and

fan speed (cannot be set by the user interface).

▪ The system does not go into operation if the room temperature is

low (<20°C).

12.3.2

To use the dry program (WITHOUT cool/

heat changeover remote control switch)

To start

1

Press the operation mode selector button on the user interface

several times and select

(program dry operation).

2

Press the ON/OFF button of the user interface.

Result:

The operation lamp lights up and the system starts

operating.

3

Press the air flow direction adjust button (only for double-flow,

multi-flow, corner, ceiling-suspended and wall-mounted). Refer

to

"12.4 Adjusting the air flow direction" on page 27

for details.

To stop

4

Press the ON/OFF button on the user interface once again.

Result:

The operation lamp goes out and the system stops

operating.

NOTICE

Do not turn off power immediately after the unit stops, but

wait for at least 5 minutes.

12.3.3

To use the dry program (WITH cool/heat

changeover remote control switch)

To start

1

Select cooling operation mode with the cool/heat changeover

remote control switch.

1

1

2

Press the operation mode selector button on the user interface

several times and select

(program dry operation).

3

Press the ON/OFF button of the user interface.

Result:

The operation lamp lights up and the system starts

operating.

4

Press the air flow direction adjust button (only for double-flow,

multi-flow, corner, ceiling-suspended and wall-mounted). Refer

to

"12.4 Adjusting the air flow direction" on page 27

for details.

To stop

5

Press the ON/OFF button on the user interface once again.

Result:

The operation lamp goes out and the system stops

operating.

NOTICE

Do not turn off power immediately after the unit stops, but

wait for at least 5 minutes.

12.4

Adjusting the air flow direction

Refer to the operation manual of the user interface.

12.4.1

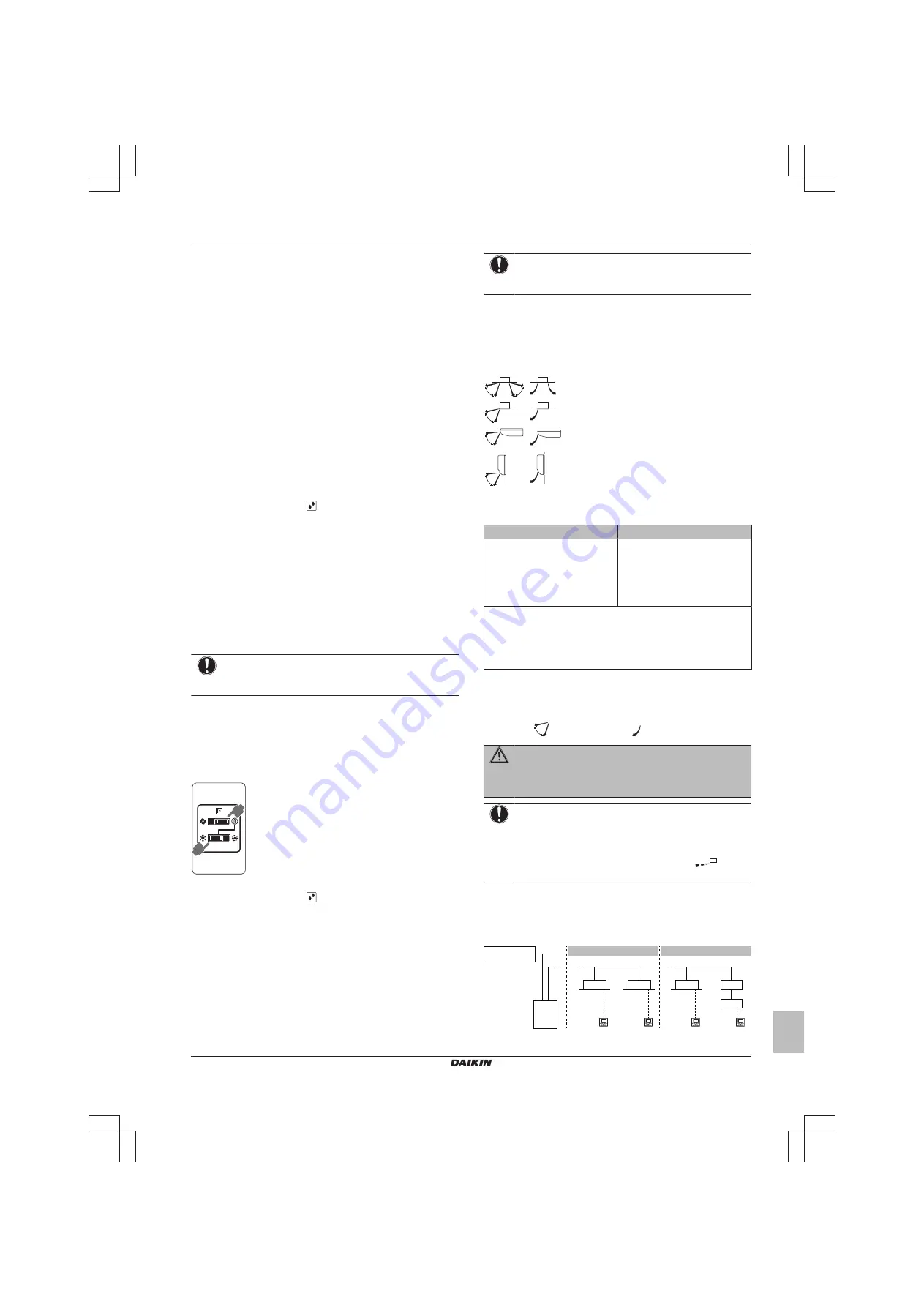

About the air flow flap

Double flow+multi-flow units

Corner units

Ceiling suspended units

Wall-mounted units

For the following conditions, a micro computer controls the air flow

direction which may be different from the display.

Cooling

Heating

▪ When the room temperature is

lower

than

the

set

temperature.

▪ When starting operation.

▪ When the room temperature is

higher

than

the

set

temperature.

▪ At defrost operation.

▪ When operating continuously at horizontal air flow direction.

▪ When continuous operation with downward air flow is performed

at the time of cooling with a ceiling-suspended or a wall-mounted

unit, the micro computer may control the flow direction, and then

the user interface indication will also change.

The air flow direction can be adjusted in one of the following ways:

▪ The air flow flap itself adjusts its position.

▪ The air flow direction can be fixed by the user.

▪ Automatic

and desired position .

WARNING

Never touch the air outlet or the horizontal blades while the

swing flap is in operation. Fingers may become caught or

the unit may break down.

NOTICE

▪ The movable limit of the flap is changeable. Contact

your dealer for details. (only for double-flow, multi-flow,

corner, ceiling-suspended and wall-mounted).

▪ Avoid operating in the horizontal direction

. It may

cause dew or dust to settle on the ceiling or flap.

12.5

Setting the master user interface

12.5.1

About setting the master user interface

d

d

c

c

a

b

VRV DX

VRV DX

VRV DX

EKEXV

AHU

d

d

1

2

1

In case of VRV DX indoor units