5 Installation

Installation and operation manual

7

RKXYQ5T7Y1B

VRV IV compressor unit for indoor installation

4P408443-1 – 2015.07

Maximum wiring length

(= distance between compressor

unit and furthest indoor unit)

300 m

Total wiring length

(= distance between compressor

unit and all indoor units, and

between compressor unit and

heat exchanger unit)

600 m

If the total transmission wiring exceeds these limits, it may

result in communication error.

5

Installation

5.1

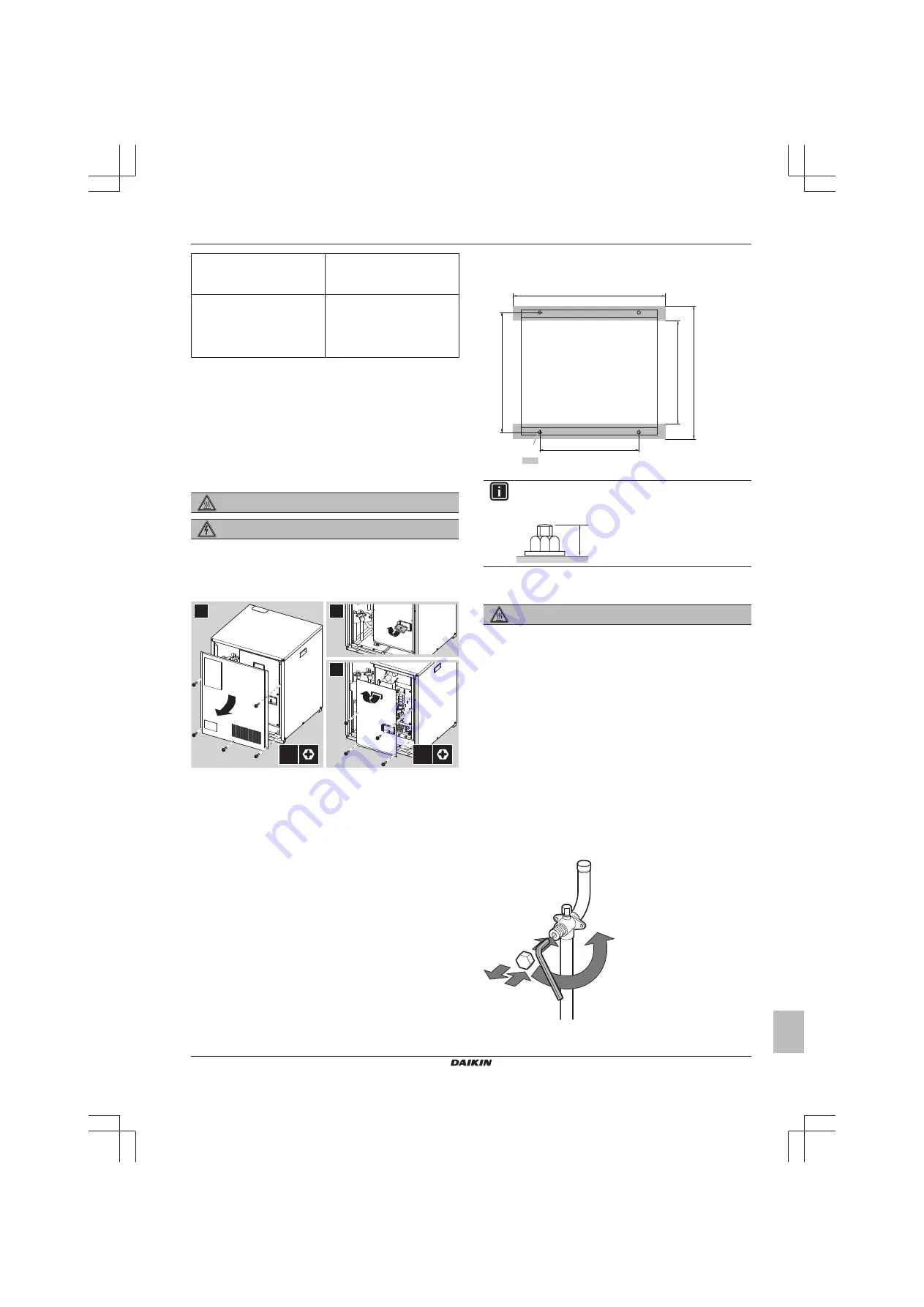

Opening the units

5.1.1

To open the compressor unit

DANGER: RISK OF BURNING

DANGER: RISK OF ELECTROCUTION

1

Remove the service cover of the compressor unit.

2

If you want to make field settings, remove the inspection cover.

3

If you want to connect electrical wiring, remove the switch box

cover.

2

3

1

5×

4×

5.2

Mounting the compressor unit

5.2.1

Guidelines when installing the

compressor unit

Check the strength and level of the installation ground so that the

unit will not cause any operating vibration or noise. If the vibration

might be transmitted to the building, use a vibration-proof rubber

(field supply).

You can install the compressor unit directly on the floor or on a

structure.

▪

On the floor.

You do NOT have to fix the unit with anchor bolts.

▪

On a structure.

Fix the unit securely with anchor bolts, nuts and

washers (field supply) to the structure. The foundation (steel beam

frame or concrete) must be larger than the grey marked area.

a

≤

480

516

≥666

426

≥640

(mm)

Minimum foundation

a

Anchor point (4×)

INFORMATION

The recommended height of the upper protruding part of

the bolts is 20 mm.

20 mm

5.3

Connecting the refrigerant piping

DANGER: RISK OF BURNING

5.3.1

Using the stop valve and service port

To handle the stop valve

▪ Make sure to keep all stop valves open during operation.

▪ The stop valve is factory closed.

To open the stop valve

1

Remove the stop valve cover.

2

Insert a hexagon wrench into the stop valve and turn the stop

valve counterclockwise.

3

When the stop valve cannot be turned any further, stop turning.

Result:

The valve is now open.

To fully open the Ø19.1 stop valve, turn the hexagonal wrench until a

torque between 27 and 33 N•m is achieved.

Inadequate torque may cause leakage of refrigerant and breakage of

the stop valve cap.

1

2

3

4