Cautions During Service Operations (Changes Required by New Refrigerants)

SiE33-003

180

New Refrigerant R-407C

6. Cautions During Service Operations (Changes Required

by New Refrigerants)

6.1

The Three Basic Rules for Refrigerant Piping Must Be More Strictly Observed

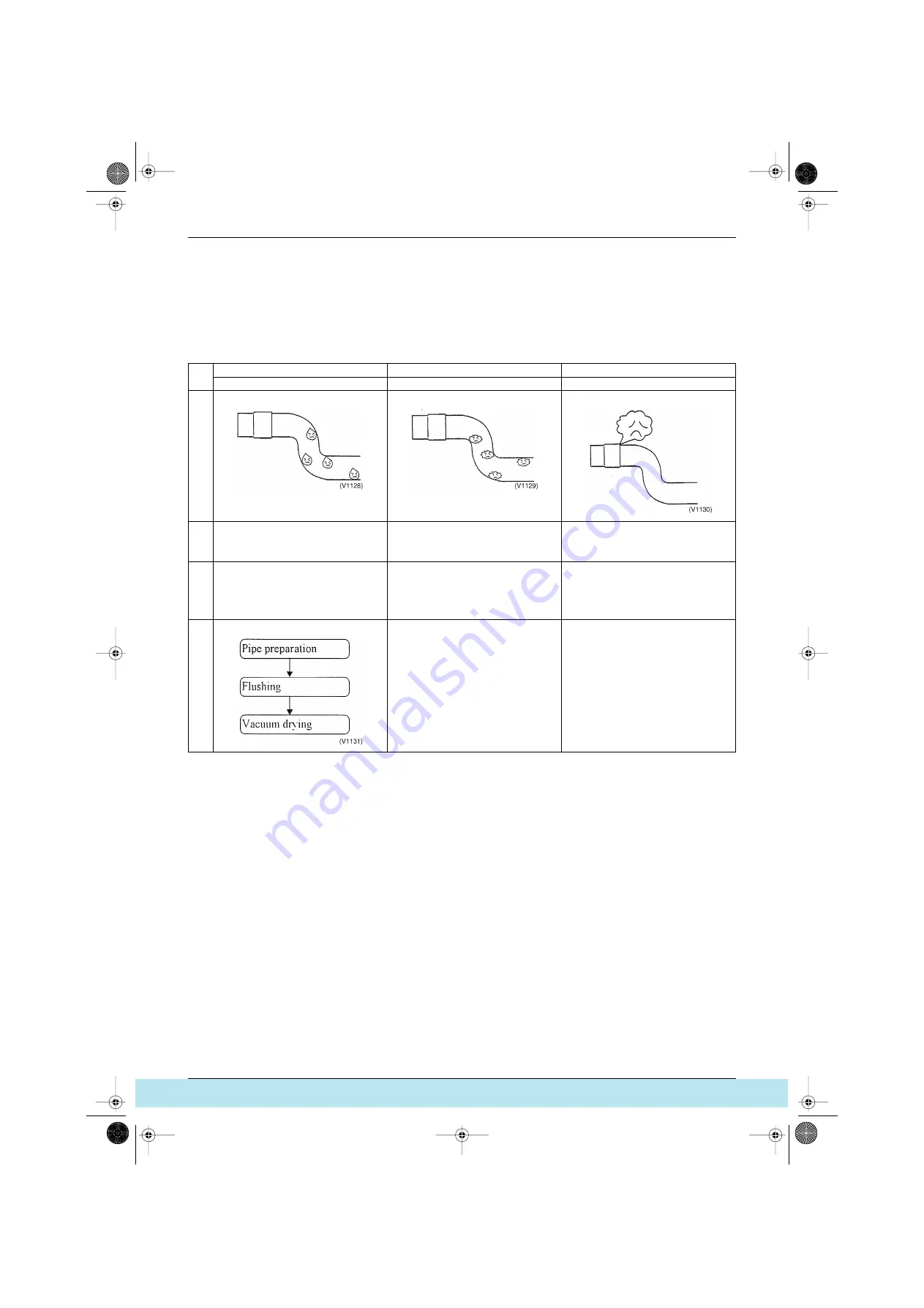

With new refrigerants, the three basic rules for refrigerant piping must be more strictly observed during

piping as well as servicing.

1. Drying (no moisture)

2. Cleaning (free of contamination)

3. Tightening (air-tightness)

There shall be no moisture in the pipe.

There shall be no dust in the pipe.

There shall be no refrigerant leak.

Item

Cause

Water entering from outside, such as

rain.

Moisture due to dew condensation

occurring inside the pipe.

Oxidized film generated during brazing.

Entering of dust, particles, oil, etc. from

outside.

Insufficient brazing.

Inadequate flaring or insufficient

tightening torque.

Inadequate flange connection.

Probrem

Clogging of expansion valve, capillary

tube, etc.

Insufficient cooling or heating.

Degradation of refringerating machine

oil.

Malfunction of compressor.

Clogging of expansion valve, capillary

tube, etc.

Insufficient cooling or heating.

Degradation of refrigerating machine oil.

Malfunction of compressor.

Gas shortage.

Insuffieient cooling or heating.

Temperature rising of discharge gas.

Degradation of refrigerating machine oil.

Malfunction of compressor.

Provenlive measure

Same as the items on the left.

Do not use tools or devices previously

used with a different type of refrigerant.

Follow the basic brazing procedure.

Follow the basic flaring procedure.

Follow the basic flange connection

procedure.

Conduct an air-tightness test

(gas leak check).

Si33-003.book Page 180 Monday, June 25, 2001 9:06 AM

Все каталоги и инструкции здесь:

http

:

//splitoff.ru/tehn-doc.html