SiBE041012

Outdoor Unit

Removal Procedure

173

2.7

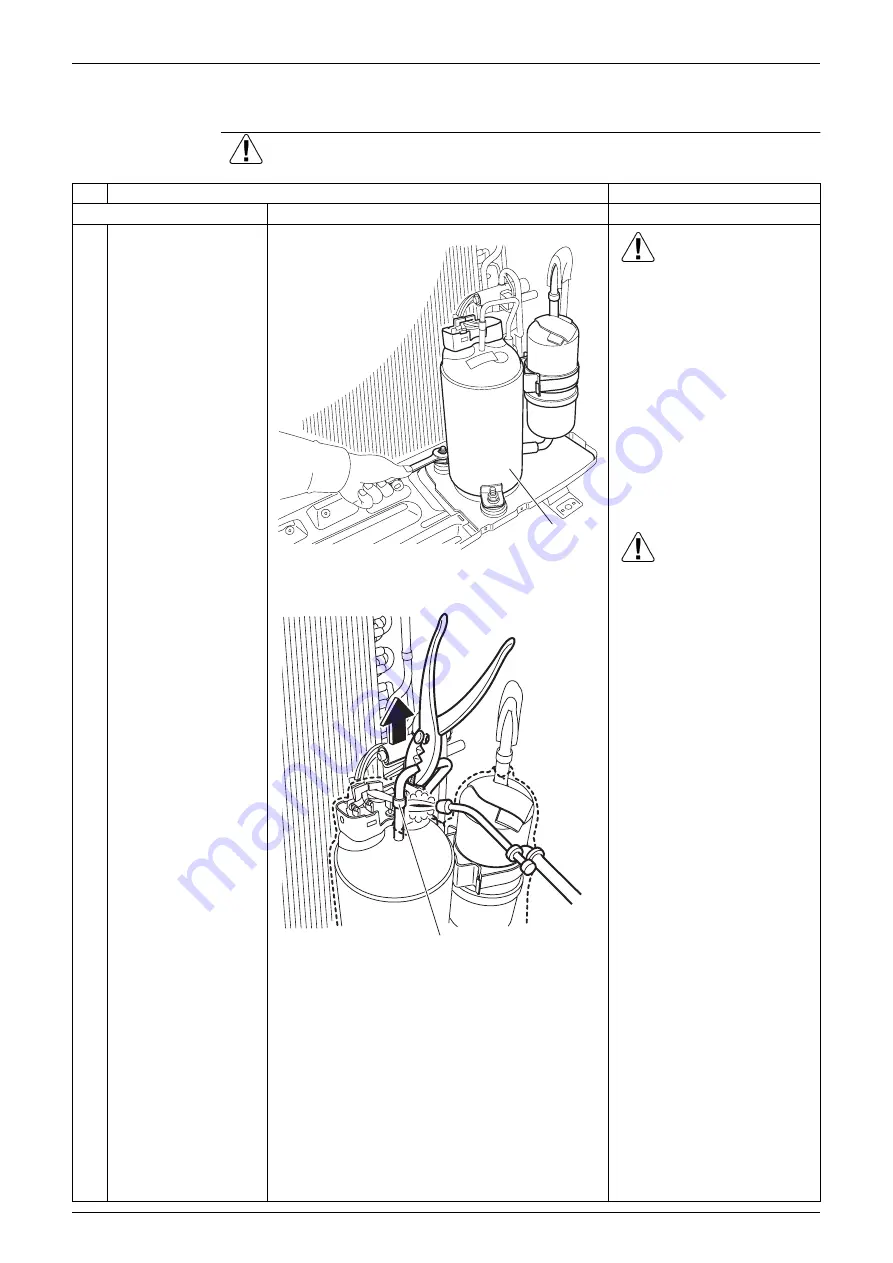

Removal of Compressor

Procedure

Warning

Be sure to wait 10 minutes or more after turning off all power supplies

before disassembling work.

Step

Procedure

Points

1. Remove the compressor.

1

Unscrew the 2 nuts of

the compressor.

Before working,

make sure that the

refrigerant is empty

in the circuit.

Be sure to apply

nitrogen

replacement when

heating up the

brazed part.

Warning

If refrigerant gas leaks during

the work, ventilate the room.

(If the refrigerant gas is

exposed to flames, toxic gas

may be generated.)

Provide a protective sheet or

a steel plate so that the

brazing flame cannot

influence peripheries.

Be careful so as not to burn

the compressor terminals or

the name plate.

Be careful so as not to burn

the heat exchanger fin.

Warning

Since it may happen that

refrigerant oil in the

compressor catches fire,

prepare wet cloth so as to

extinguish fire immediately.

In case of difficulty with gas

brazing machine

1. Disconnect the brazed part

where is easy to disconnect

and restore.

2. Cut pipes on the main unit

with a tube cutter in order to

make it easy to disconnect.

Cautions for restoration

1. Restore the piping by non-

oxidation brazing.

2. It is required to prevent the

carbonization of the oil inside

the four way valve and the

deterioration of the gaskets

affected by heat. For the

sake of this, wrap the four

way valve with wet cloth and

provide water so that the

cloth does not dry and avoid

excessive heating. (Keep

below 120°C)

Note:

Do not use a metal saw for

cutting pipes by all means

because the sawdust comes

into the circuit.

2

Heat up the brazed part

of the discharge side

and disconnect.

Compressor

(R11889)

(R12031)

Discharge side