Correct configuration

1

7RLQGRRUXQLW

,IWKHSLSLQJOHQJWKEHWZHHQWKHRXWGRRUXQLWVH[FHHGVP

FUHDWHDULVHRIPPRUPRUHLQWKHJDVOLQHZLWKLQDOHQJWKRI

PIURPWKHNLW

If

≤

2 m

1

7RLQGRRUXQLW

2

3LSLQJEHWZHHQRXWGRRUXQLWV

If >2 m

1

7RLQGRRUXQLW

2

3LSLQJEHWZHHQRXWGRRUXQLWV

1

1

1

1

2

1

10. Precautions on refrigerant piping

'RQRWDOORZDQ\WKLQJRWKHUWKDQWKHGHVLJQDWHGUHIULJHUDQWWR

JHWPL[HGLQWRWKHUHIULJHUDQWF\FOHVXFKDVDLUQLWURJHQHWF,I

DQ\UHIULJHUDQWJDVOHDNVZKLOHZRUNLQJRQWKHXQLWYHQWLODWHWKH

URRPWKRURXJKO\ULJKWDZD\

8VH5$RQO\ZKHQDGGLQJUHIULJHUDQW

,QVWDOODWLRQWRROV

0DNHVXUHWRXVHLQVWDOODWLRQWRROVJDXJHPDQLIROGFKDUJH

KRVHHWFWKDWDUHH[FOXVLYHO\XVHGIRU5$LQVWDOODWLRQVWR

ZLWKVWDQGWKHSUHVVXUHDQGWRSUHYHQWIRUHLJQPDWHULDOVHJ

PLQHUDORLOVDQGPRLVWXUHIURPPL[LQJLQWRWKHV\VWHP

9DFXXPSXPS

8VHDVWDJHYDFXXPSXPSZLWKDQRQUHWXUQYDOYH

0DNHVXUHWKHSXPSRLOGRHVQRWIORZRSSRVLWHO\LQWRWKH

V\VWHPZKLOHWKHSXPSLVQRWZRUNLQJ

8VHDYDFXXPSXPSZKLFKFDQHYDFXDWHWR±N3D

7RUU±PP+J

Protection against contamination when installing pipes

7DNHPHDVXUHVWRSUHYHQWIRUHLJQPDWHULDOVOLNHPRLVWXUHDQG

FRQWDPLQDWLRQIURPPL[LQJLQWRWKHV\VWHP

%ORFNDOOJDSVLQWKHKROHVIRUSDVVLQJRXWSLSLQJDQGZLULQJXVLQJ

VHDOLQJPDWHULDOILHOGVXSSO\WKHFDSDFLW\RIWKHXQLWZLOOGURSDQG

VPDOODQLPDOVPD\HQWHUWKHPDFKLQH

([DPSOHSDVVLQJSLSLQJRXWWKURXJKWKHIURQW

8VHFOHDQSLSHVRQO\

+ROGWKHSLSHHQGGRZQZDUGVZKHQUHPRYLQJEXUUV

&RYHUWKHSLSHHQGZKHQLQVHUWLQJLWWKURXJKDZDOOVRWKDWQR

GXVWRUGLUWHQWHUVWKHSLSH

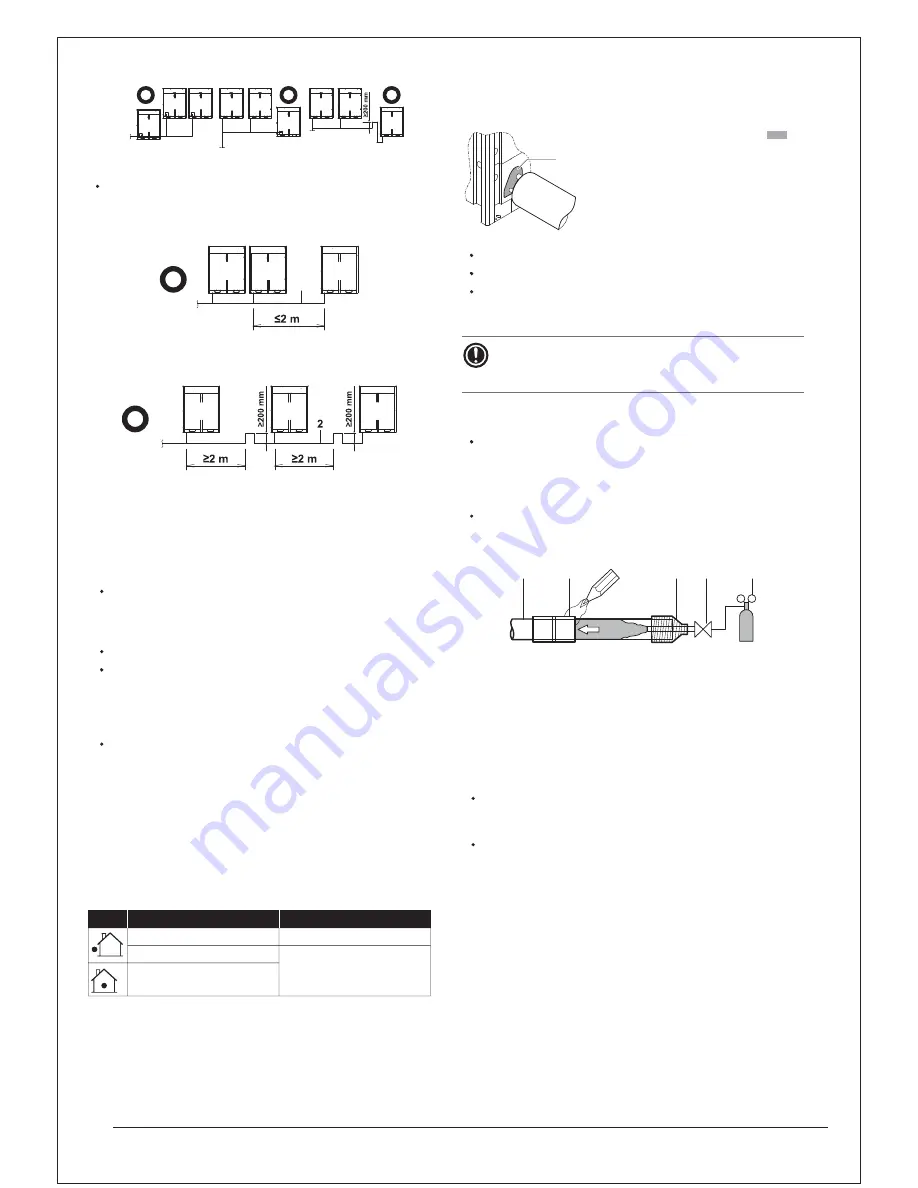

10.1 Caution for brazing

0DNHVXUHWREORZWKURXJKZLWKQLWURJHQZKHQEUD]LQJ%ORZLQJ

WKURXJKZLWKQLWURJHQSUHYHQWVWKHFUHDWLRQRIODUJHTXDQWLWLHVRI

R[LGL]HGILOPRQWKHLQVLGHRIWKHSLSLQJ$QR[LGL]HGILOP

DGYHUVHO\DIIHFWVYDOYHVDQGFRPSUHVVRUVLQWKHUHIULJHUDWLQJ

V\VWHPDQGSUHYHQWVSURSHURSHUDWLRQ

7KHQLWURJHQSUHVVXUHVKRXOGEHVHWWR03DLHMXVW

HQRXJKVRLWFDQEHIHOWRQWKHVNLQZLWKDSUHVVXUHUHGXFLQJ

YDOYH

1

5HIULJHUDQWSLSLQJ

2

3DUWWREHEUD]HG

3

7DSLQJ

4

+DQG\YDOYH

5

3UHVVXUHUHGXFLQJYDOYH

6

1LWURJHQ

In

Place

stallation period

Protection method

0RUHWKDQDPRQWK

3LQFKWKHSLSH

/HVVWKDQDPRQWK

3LQFKRUWDSHWKHSLSH

5HJDUGOHVVRIWKHSHULRG

NOTICE

$IWHUDOOWKHSLSLQJKDVEHHQFRQQHFWHGPDNHVXUHWKHUHLV

QRJDVOHDN8VHQLWURJHQWRSHUIRUPDJDVOHDNGHWHFWLRQ

1

1

&ORVHWKHDUHDVPDUNHGZLWK

:KHQWKHSLSLQJLVURXWHGIURPWKH

IURQWSDQHO

1

2

3

4

5

6

6

'RQRWXVHDQWLR[LGDQWVZKHQEUD]LQJWKHSLSHMRLQWV5HVLGXHFDQ

FORJSLSHVDQGEUHDNHTXLSPHQW

'RQRWXVHIOX[ZKHQEUD]LQJFRSSHUWRFRSSHUUHIULJHUDQW

SLSLQJ8VHSKRVSKRUFRSSHUEUD]LQJILOOHUDOOR\%&X3ZKLFK

GRHVQRWUHTXLUHIOX[

)OX[KDVDQH[WUHPHO\KDUPIXOLQIOXHQFHRQUHIULJHUDQWSLSLQJ

V\VWHPV)RULQVWDQFHLIFKORULQHEDVHGIOX[LVXVHGLWZLOOFDXVH

SLSHFRUURVLRQRULQSDUWLFXODULI WKHIOX[FRQWDLQVIOXRULQHLWZLOO

GHWHULRUDWHWKHUHIULJHUDQWRLO

Summary of Contents for RXQ10AYM

Page 12: ......

Page 28: ...1 T 2 3 4 5 6 NOTICE N 1 2 3 4 5 RXQ6 12 N N N N 8 2 1 6 7 6 6 4 5 4 3 3 6 ...

Page 38: ...Value 2 11 Meaning Level N N N 5 15 2 Mode 2 95 95 5 Value 2 8 Te target 95 95 1 1 N N ...

Page 39: ...959 5 N N 959 1 5 959 9 5 3 3 9 5 9 1 95 9 N 3 3 9 9 9 3 9 3 ...

Page 50: ...5 1 7 RLQW UDQFK LW 53 7 53 7 C D3K05234B Unit mm Unit mm ...

Page 51: ... 53 7 53 7 C D3K05236B Unit mm Unit mm ...

Page 52: ... 53 7 53 7 53 7 53 7 ...

Page 53: ......

Page 56: ... 53 0 53 0 53 0 53 0 ...

Page 57: ......

Page 58: ...5HGXFHU 53 0 73 53 0 3 ...

Page 59: ...2XWGRRU 8QLW 0XOWL RQQHFWLRQ 3LSLQJ LW 3 3 3D052312 Unit mm Gas side Unit mm Liquid side ...

Page 60: ... 3 3 3D052314 Unit mm Gas side Unit mm Liquid side ...

Page 61: ... 3 3 3 3 ...

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ...5 4 0 5 4 0 5 4 0 5 4 0 ...

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ...5 4 0 5 4 0 5 4 0 5 4 0 ...

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......