Troubleshooting

ESIE04-01

3–4

Part 3 – Troubleshooting

3

1

3

4

5

1.2

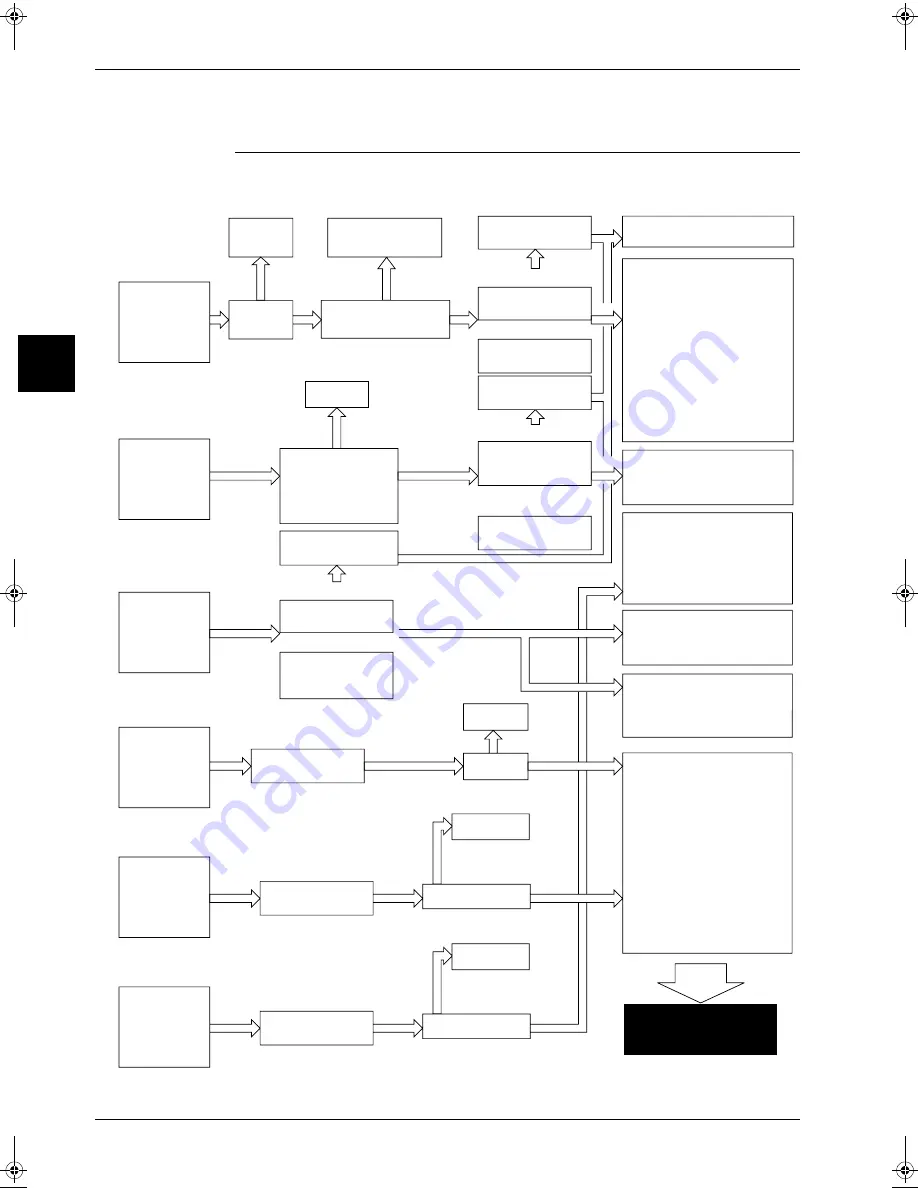

General Troubleshooting Flowchart

Find out the situation according to the following procedure when there is a request for service from the

customer.

YES

NO

NO

NO

NO

NO

Cooling

Heating

NO

NO

YES

YES

YES

Runs

Runs

Nomal

Nomal

Doesn't run

YES

YES

YES

NO

YES

(Service work required)

OK.We'll be right over.

(S1989)

Troubleshooting by remote

controller malfunction

code.

Turn the power supply

switch ON or replace

the fuse.

Wait until

power failure

is over.

Is there a

power

failure?

Doesn't run at all

The power supply switch is

OFF or the switch's fuse is

burnt.

Set the remote

controller's temperature

setting to:

(1)When

cooling:Minimum

(2)When

heating:Maximum

The fan comes on

but the

compressor

doesn't run.

Cooling starts but

stops right away.

Is the remote

controller's operation

lamp blinking?

Is the remote controller's

operation lamp blinking?

Machines equipped with

wireless remote controllers only.

Is the operation lamp of the

indoor unit's signal receiving

section blinking?

Is the operation lamp of the

indoor unit's signal receiving

section blinking?

Units equipped with wireless

remote controller only.

Troubleshooting by remote

controller malfunction

code.

Ask for the character

code of the malfunction

code.

Refer to "Remote controller display

malfunction code and contents".

Units equipped with liquid

crystal remote controllers only

Units equipped with wireless

remote controllers only

Is the remote

controller's operation

lamp blinking?

Try turning the

Operation switch OFF

and On.

The unit won't run

again for a while

after stopping.

The unit runs but

doesn't cool the

room.

Is the operation lamp of

the indoor unit's signal

receiving section

blinking?

Measure the suction

/disharge temperature.

Units equipped with liquid

crystal remote controllers only

Units equipped with wireless

remote controllers only

Did you allow 3 minutes to

elapse after turning ON?

Is there something causing the

indoor load to be large, such as

an open window or door?

(Temperature differential

=suction temperature - discharge temperature)

Units equipped with liquid

crystal remote controllers only

Operation is

normal.

Temperature

differential is 8~18˚C

The units runs but

doesn't heat the

room.

Measure the suction

/discharge temperature.

Is there something causing the

indoor heat load to be large, such

as an open window or door?

(Temperature differential

=discharge temperature - suction temperature)

Operation is

normal.

Temperature

differential is 14~30˚C

(1) The operation circuit fuse is

disconnected or is making poor contact.

(2) The operation swich is broken or its

contact is defective.

(3) The high pressure switch is broken.

(4) The fan motor's magnetic switch is

broken.

(5) The fan motor's overcurrent relay is

being actuated or is broken.

(6) The compressor's overcurrent relay is

broken.

(7) The compressor's protective thermostat

is broken.

(8) The electrical system insulation is

defective.

(9) The compressor's magnetic switch's

contact is defective.

(10) The compressor is broken.

(11) Thermostat is broken.

(12) The cool/heat selector is broken.

(13) The operation switch is broken.

(14) The compressor's magnetic swich is

broken.

(15) Over-charged with refrigerant.

(16) Air is mixed inside the refrigerant

circuit.

(17) The pressure switch is broken.

(18) The outdoor unit fan motor's magnetic

switch is broken.

(19) The outdoor unit fan motor's auxiliary

relay is broken.

(20) The outdoor unit's heat exchanger is

dirty.

(21) There is something blocking the

outdoor unit's air flow.

(22) Malfunction of the outdoor unit's fan.

(23) The indoor unit's air filter is dirty.

(24) The indoor unit's heat exhanger is

dirty.

(25) There is something blocking the indoor

unit's air flow.

(26) Malfunction of the indoor unit's fan.

(27) Overcurrent relay (for compressor)

(28) Compressor's protective themostat

(29) The causes for the overcurrent relay

(for compressor) being actuated are:

(29)-1 Power supply voltage is lower than

prescribed.

(29)-2 High pressure is too high.

(29)-3 The power supply cord is too small.

(29)-4 The compressor is broken.

(30) The causes for the compressor's

protective thermostat

(30)-1 Internal leak of the-4way valve

(No substantial difference between

suction and discharge temperature.

(30)-2 Unsatisfactory compression from

the compressor

(30)-3 Different kind of refrigerant is charged.

(30)-4 Malfunction of the expansion valve

(30)-5 Unsatisfactory refrigerant circulation

RZQ - Final.book Page 4 Wednesday, September 8, 2004 8:40 AM

Summary of Contents for RZQ71~125B7V3B

Page 1: ...Service Manual ESIE04 01 RZQ71 125B7V3B Sky Air Inverter R 410A B series ...

Page 2: ......

Page 24: ...ESIE04 01 1 2 Part 1 System Outline 3 1 1 5 ...

Page 32: ...General Outline Outdoor Units ESIE04 01 1 10 Part 1 System Outline 3 1 1 4 5 ...

Page 64: ...General Outline Indoor Units ESIE04 01 1 42 Part 1 System Outline 3 1 1 4 5 ...

Page 76: ...Specifications ESIE04 01 1 54 Part 1 System Outline 3 1 1 4 5 ...

Page 92: ...Functional Diagrams ESIE04 01 1 70 Part 1 System Outline 3 1 1 4 5 ...

Page 94: ...ESIE04 01 1 72 Part 1 System Outline ...

Page 122: ...Wiring Diagrams ESIE04 01 1 100 Part 1 System Outline 3 1 1 4 5 ...

Page 140: ...ESIE04 01 2 2 Part 2 Functional Description 3 1 2 5 ...

Page 162: ...General Functionality ESIE04 01 2 24 Part 2 Functional Description 3 1 2 4 5 ...

Page 200: ...Outdoor Unit Functional Concept ESIE04 01 2 62 Part 2 Functional Description 3 1 2 4 5 ...

Page 202: ...ESIE04 01 3 2 Part 3 Troubleshooting 3 1 3 5 ...

Page 288: ...Error Codes Outdoor Units ESIE04 01 3 88 Part 3 Troubleshooting 3 1 3 4 5 ...

Page 312: ...Additional Checks for Troubleshooting ESIE04 01 3 112 Part 3 Troubleshooting 3 1 3 4 5 ...

Page 314: ...ESIE04 01 4 2 Part 4 Commissioning and Test Run 3 1 4 5 ...

Page 356: ...ESIE04 01 5 2 Part 5 Disassembly and Maintenance 3 1 5 ...

Page 484: ...ESIE04 01 viii Index 3 1 4 5 ...