ESIE04-01

Disassembly and Maintenance: Outdoor Units

Part 5 – Disassembly and Maintenance

5–15

3

5

1

5

1.2.9

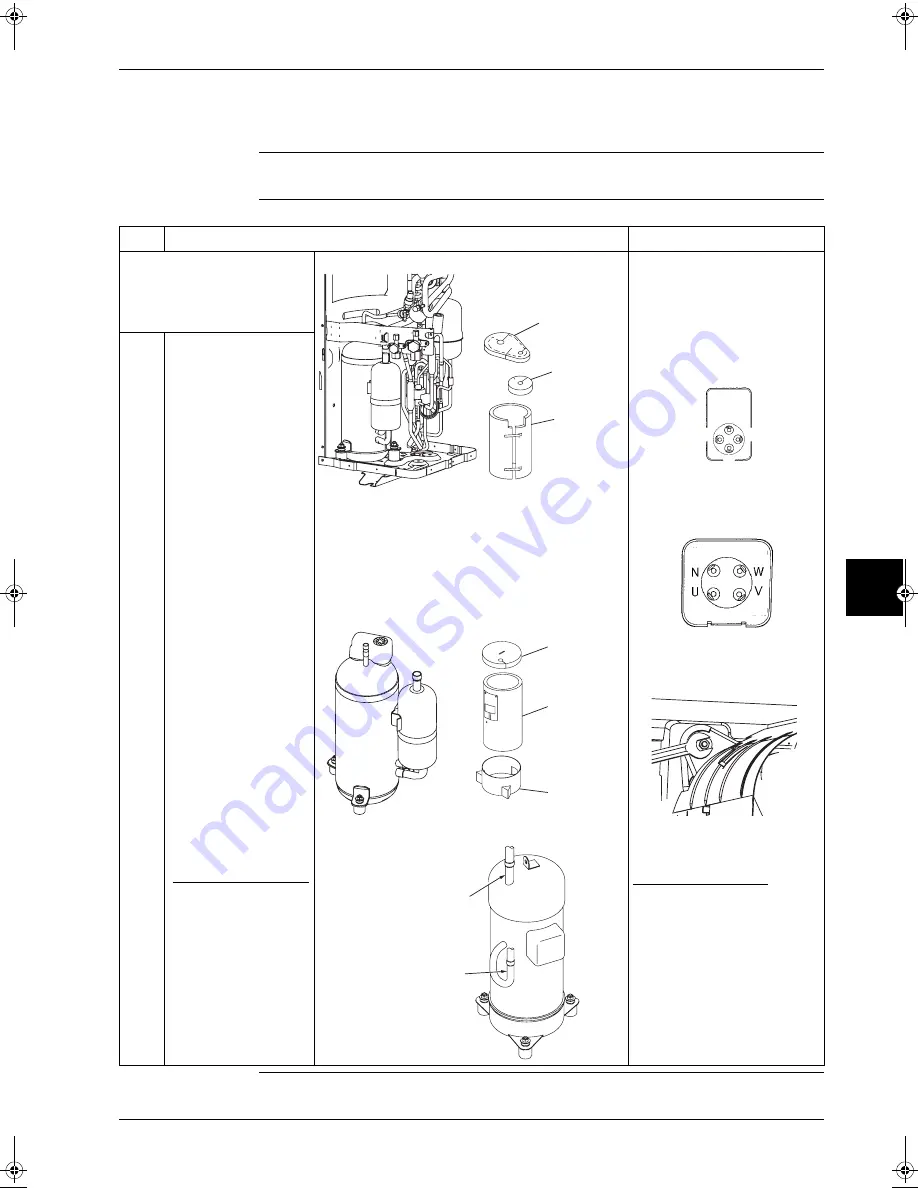

Removal of Compressor

Warning

Be sure to wait 10 minutes or more after turning off all power supplies before disassembling work.

Procedure

Step

Procedure

Points

P

Remove the parts related to

the outside panel and the

switch box in accordance with

the Removal Procedure for

Outside Panel and others.

P

RZQ71B7V3B

P

Compressor for RZQ71B7V3B

P

Compressor for RZQ100~125B7V3B

P

Check to be sure there are no

more refrigerants left in the

unit before starting this

removal.

P

Color of terminal pins

P

RZQ71B7V3B

P

RZQ100-125B7V3B

P

One out of the two nuts that fix

the compressor is located

outside the partition plate.

Caution:

For RZQ100-125B7V3B

If the brazed sections are directly

stripped off from the pipes, oil

may catch fire.

Be sure to cut the pipes in

advance with a pipe cutter.

1

Unscrew the five screws

from the stop valve

mounting plate.

2

Disconnect the gas

piping and liquid piping.

3

Push the protrusion from

both sides to remove the

terminal cover.

4

Remove the lead wires

from the terminal pins.

5

Remove the sound

insulation (1), (2), and

(3), and

vibration-isolating putty.

6

Unlock the nuts (*) that fix

the compressor.

A total of three nuts are

provided.

7

Strip off the brazed

sections (in two places*).

*For RZQ100-125B7V3B

Before stripping off the

brazed sections, be sure

to cut the suction and

discharge pipes with a

pipe cutter.

(See Caution in the

column of Points.)

8

Lift up the compressor to

pull out it.

Sound

insulation (2)

Vibration-

isolating putty

Sound

insulation (1)

Sound

insulation (2)

Sound

insulation (1)

Sound

insulation (3)

Cut here

(on suction pipe)

Cut here

(on discharge pipe)

(Yellow)

V

N

(Brown)

U (Red)

(Blue) W

(Brown)

(Blue)

(Red)

(White)

RZQ - Final.book Page 15 Wednesday, September 8, 2004 8:40 AM

Summary of Contents for RZQ71~125B7V3B

Page 1: ...Service Manual ESIE04 01 RZQ71 125B7V3B Sky Air Inverter R 410A B series ...

Page 2: ......

Page 24: ...ESIE04 01 1 2 Part 1 System Outline 3 1 1 5 ...

Page 32: ...General Outline Outdoor Units ESIE04 01 1 10 Part 1 System Outline 3 1 1 4 5 ...

Page 64: ...General Outline Indoor Units ESIE04 01 1 42 Part 1 System Outline 3 1 1 4 5 ...

Page 76: ...Specifications ESIE04 01 1 54 Part 1 System Outline 3 1 1 4 5 ...

Page 92: ...Functional Diagrams ESIE04 01 1 70 Part 1 System Outline 3 1 1 4 5 ...

Page 94: ...ESIE04 01 1 72 Part 1 System Outline ...

Page 122: ...Wiring Diagrams ESIE04 01 1 100 Part 1 System Outline 3 1 1 4 5 ...

Page 140: ...ESIE04 01 2 2 Part 2 Functional Description 3 1 2 5 ...

Page 162: ...General Functionality ESIE04 01 2 24 Part 2 Functional Description 3 1 2 4 5 ...

Page 200: ...Outdoor Unit Functional Concept ESIE04 01 2 62 Part 2 Functional Description 3 1 2 4 5 ...

Page 202: ...ESIE04 01 3 2 Part 3 Troubleshooting 3 1 3 5 ...

Page 288: ...Error Codes Outdoor Units ESIE04 01 3 88 Part 3 Troubleshooting 3 1 3 4 5 ...

Page 312: ...Additional Checks for Troubleshooting ESIE04 01 3 112 Part 3 Troubleshooting 3 1 3 4 5 ...

Page 314: ...ESIE04 01 4 2 Part 4 Commissioning and Test Run 3 1 4 5 ...

Page 356: ...ESIE04 01 5 2 Part 5 Disassembly and Maintenance 3 1 5 ...

Page 484: ...ESIE04 01 viii Index 3 1 4 5 ...