Summary of Contents for RZQG71~140L7V1B

Page 2: ......

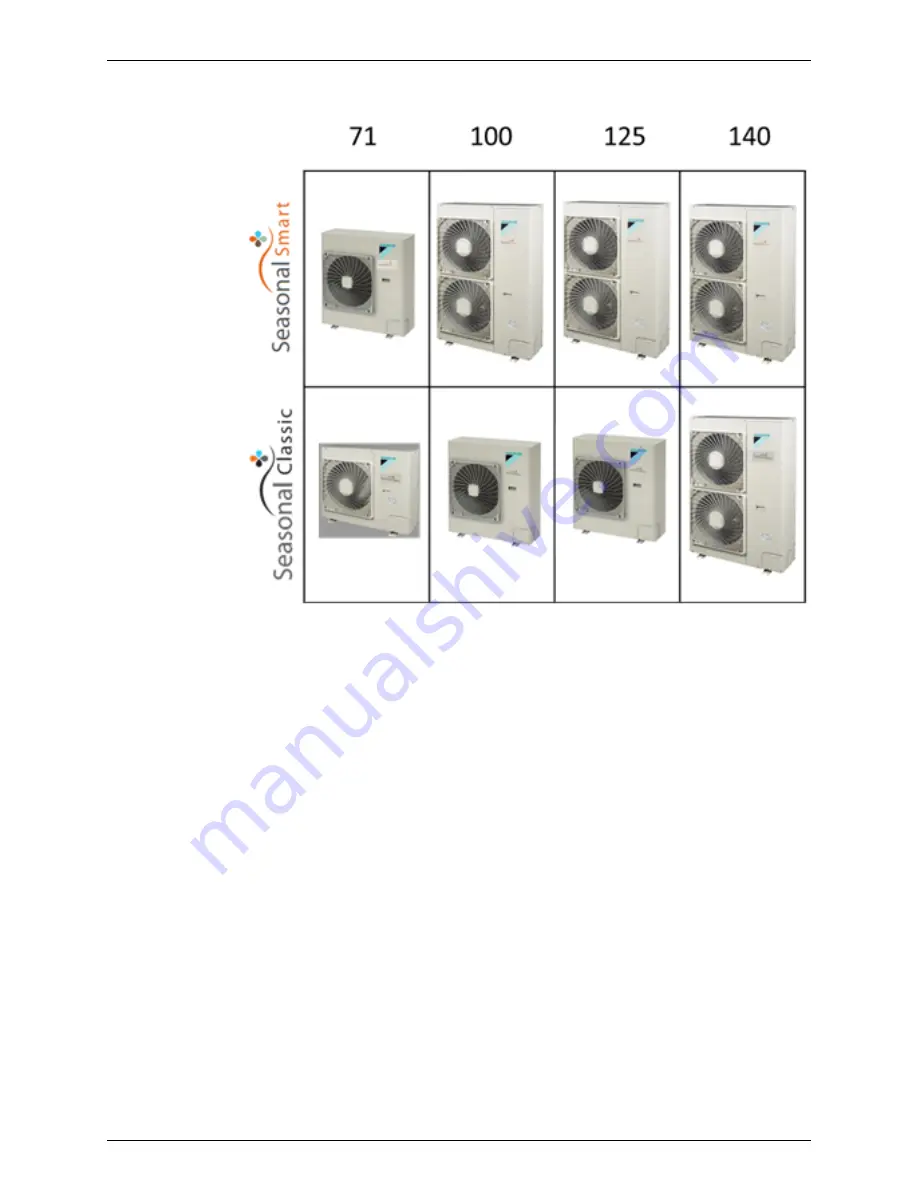

Page 14: ...ESIE12 06 Outlook Outdoor Units General Information 3 2 Outlook Outdoor Units...

Page 15: ...Outlook Outdoor Units ESIE12 06 4 General Information...

Page 16: ...ESIE12 06 Functions 5 Part 2 Functions 1 Functions 5 1 1 Indoor Unit 5 1 2 Outdoor Unit 5...

Page 18: ...ESIE12 06 Specifications 7 Part 3 Specifications 1 Specifications 8 2 Operation range 75...

Page 19: ...Specifications ESIE12 06 8 Specifications 1 Specifications RZQG71V FVQ71CVEB RZQG71L7V1B...

Page 20: ...ESIE12 06 Specifications Specifications 9 FUQ71BWV1B RZQG71L7V1B FUQ71BVV1B RZQG71L7V1B...

Page 21: ...Specifications ESIE12 06 10 Specifications FHQG71CVEB RZQG71L7V1B FCQHG71FVEB RZQG71L7V1B...

Page 22: ...ESIE12 06 Specifications Specifications 11 FCQG71FVEB RZQG71L7V1B FBQ71C8VEB RZQG71L7V1B...

Page 23: ...Specifications ESIE12 06 12 Specifications FAQ71CVEB RZQG71L7V1B...

Page 24: ...ESIE12 06 Specifications Specifications 13 RZQG71L7V1B...

Page 25: ...Specifications ESIE12 06 14 Specifications RZQG71Y FVQ71CVEB RZQG71L7Y1B...

Page 26: ...ESIE12 06 Specifications Specifications 15 FUQ71BWV1B RZQG71L7Y1B FHQG71CVEB RZQG71L7Y1B...

Page 27: ...Specifications ESIE12 06 16 Specifications FCQHG71FVEB RZQG71L7Y1B FCQG71FVEB RZQG71L7Y1B...

Page 28: ...ESIE12 06 Specifications Specifications 17 FBQ71C8VEB RZQG71L7Y1B FAQ71CVEB RZQG71L7Y1B...

Page 29: ...Specifications ESIE12 06 18 Specifications RZQG71L7Y1B...

Page 31: ...Specifications ESIE12 06 20 Specifications FUQ100BVV1B RZQG100L7V1B FHQG100CVEB RZQG100L7V1B...

Page 32: ...ESIE12 06 Specifications Specifications 21 FCQHG100FVEB RZQG100L7V1B FCQG100FVEB RZQG100L7V1B...

Page 33: ...Specifications ESIE12 06 22 Specifications FBQ100C8VEB RZQG100L7V1B FAQ100CVEB RZQG100L7V1B...

Page 34: ...ESIE12 06 Specifications Specifications 23 RZQG100L7V1B...

Page 36: ...ESIE12 06 Specifications Specifications 25 FHQG100CVEB RZQG100L7Y1B FCQHG100FVEB RZQG100L7Y1B...

Page 37: ...Specifications ESIE12 06 26 Specifications FCQG100FVEB RZQG100L7Y1B FBQ100C8VEB RZQG100L7Y1B...

Page 38: ...ESIE12 06 Specifications Specifications 27 FAQ100CVEB RZQG100L7Y1B...

Page 39: ...Specifications ESIE12 06 28 Specifications RZQG100L7Y1B...

Page 41: ...Specifications ESIE12 06 30 Specifications FUQ125BVV1B RZQG125L7V1B FHQG125CVEB RZQG125L7V1B...

Page 42: ...ESIE12 06 Specifications Specifications 31 FDQ125C7VEB RZQG125L7V1B FCQHG125FVEB RZQG125L7V1B...

Page 43: ...Specifications ESIE12 06 32 Specifications FCQG125FVEB RZQG125L7V1B FBQ125C8VEB RZQG125L7V1B...

Page 44: ...ESIE12 06 Specifications Specifications 33 RZQG125L7V1B...

Page 46: ...ESIE12 06 Specifications Specifications 35 FHQG125CVEB RZQG125L7Y1B FDQ125C7VEB RZQG125L7Y1B...

Page 47: ...Specifications ESIE12 06 36 Specifications FCQHG125FVEB RZQG125L7Y1B FCQG125FVEB RZQG125L7Y1B...

Page 48: ...ESIE12 06 Specifications Specifications 37 FBQ125C8VEB RZQG125L7Y1B...

Page 49: ...Specifications ESIE12 06 38 Specifications RZQG125L7Y1B...

Page 51: ...Specifications ESIE12 06 40 Specifications FCQHG140FVEB RZQG140L7V1B FCQG140FVEB RZQG140L7V1B...

Page 52: ...ESIE12 06 Specifications Specifications 41 FBQ140C8VEB RZQG140L7V1B...

Page 53: ...Specifications ESIE12 06 42 Specifications RZQG140L7V1B...

Page 55: ...Specifications ESIE12 06 44 Specifications FCQHG140FVEB RZQG140L7Y1B FCQG140FVEB RZQG140L7Y1B...

Page 56: ...ESIE12 06 Specifications Specifications 45 FBQ140C8VEB RZQG140L7Y1B...

Page 57: ...Specifications ESIE12 06 46 Specifications RZQG140L7Y1B...

Page 59: ...Specifications ESIE12 06 48 Specifications FCQHG71FVEB RZQSG71L2V1B FCQG71FVEB RZQSG71L2V1B...

Page 60: ...ESIE12 06 Specifications Specifications 49 FBQ71C8VEB RZQSG71L2V1B FAQ71CVEB RZQSG71L2V1B...

Page 61: ...Specifications ESIE12 06 50 Specifications RZQSG71L2V1B...

Page 64: ...ESIE12 06 Specifications Specifications 53 FBQ100C8VEB RZQSG100L7V1B FAQ100CVEB RZQSG100L7V1B...

Page 65: ...Specifications ESIE12 06 54 Specifications RZQSG100L7V1B...

Page 68: ...ESIE12 06 Specifications Specifications 57 FBQ100C8VEB RZQSG100L7Y1B FAQ100CVEB RZQSG100L7Y1B...

Page 69: ...Specifications ESIE12 06 58 Specifications RZQSG100L7Y1B...

Page 72: ...ESIE12 06 Specifications Specifications 61 FCQG125FVEB RZQSG125L7V1B FBQ125C8VEB RZQSG125L7V1B...

Page 73: ...Specifications ESIE12 06 62 Specifications RZQSG125L7V1B...

Page 76: ...ESIE12 06 Specifications Specifications 65 FCQG125FVEB RZQSG125L7Y1B FBQ125C8VEB RZQSG125L7Y1B...

Page 77: ...Specifications ESIE12 06 66 Specifications RZQSG125L7Y1B...

Page 80: ...ESIE12 06 Specifications Specifications 69 FBQ140C8VEB RZQSG140L7V1B...

Page 81: ...Specifications ESIE12 06 70 Specifications RZQSG140L7V1B...

Page 84: ...ESIE12 06 Specifications Specifications 73 FBQ140C8VEB RZQSG140L7Y1B...

Page 85: ...Specifications ESIE12 06 74 Specifications RZQSG140L7Y1B...

Page 86: ...ESIE12 06 Operation range Specifications 75 2 Operation range Smart...

Page 87: ...Operation range ESIE12 06 76 Specifications EDP...

Page 88: ...ESIE12 06 Operation range Specifications 77 Classic...

Page 89: ...Operation range ESIE12 06 78 Specifications...

Page 131: ...Function Details ESIE12 06 120 Function and Control limit and or Tc Upper limit...

Page 161: ...Field Setting from Outdoor Unit PCB ESIE12 06 150 Field Setting Outdoor unit...

Page 162: ...ESIE12 06 Field Setting from Outdoor Unit PCB Field Setting 151 3 2 7 Troubleshooting...

Page 165: ...Emergency Operation ESIE12 06 154 Field Setting...

Page 265: ...ESIE12 06 254 Service Diagnosis...

Page 279: ...Precautions for New Refrigerant R 410A ESIE12 06 268 Appendix...