6 Installation

Installer reference guide

14

RZQG71~Y1 + RZQSG100~Y1

Split system air conditioners

4P385522-1A – 2016.10

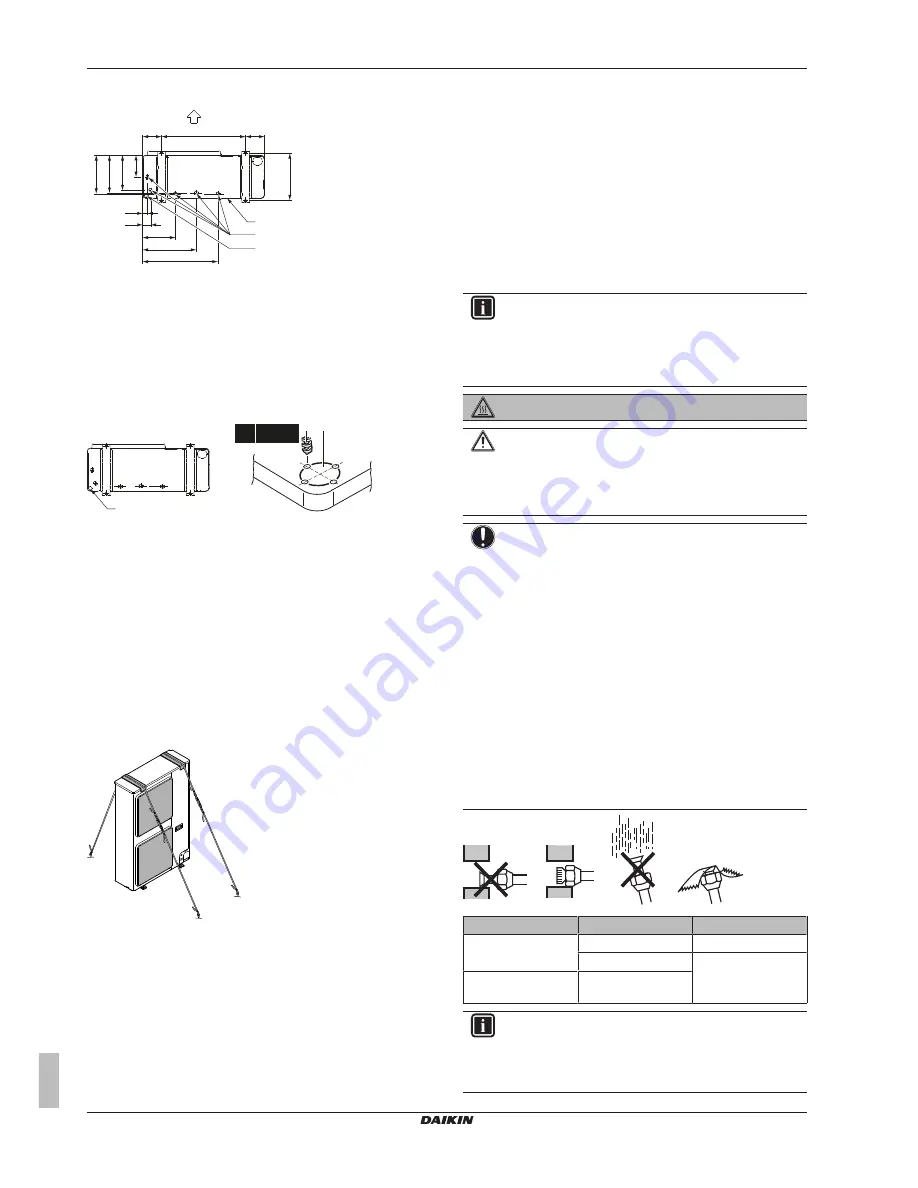

Drain holes (dimensions in mm)

A

B

B

C

D

E

160

160

620

36

61

262

416

595

285

279

260

161

(345~355)

A

Discharge side

B

Distance between anchor points

C

Bottom frame

D

Drain holes

E

Knockout hole for snow

Snow

In regions with snowfall, snow might build up and freeze between the

heat exchanger and the external plate. This might decrease the

operating efficiency. To prevent this:

1

Drill (a, 4×) and remove the knockout hole (b).

b

a b

4× Ø6 mm

2

Remove the burrs, and paint the edges and areas around the

edges using repair paint to prevent rusting.

6.3.6

To prevent the outdoor unit from falling

over

In case the unit is installed in places where strong wind can tilt the

unit, take following measure:

1

Prepare 2 cables as indicated in the following illustration (field

supply).

2

Place the 2 cables over the outdoor unit.

3

Insert a rubber sheet between the cables and the outdoor unit

to prevent the cable from scratching the paint (field supply).

4

Attach the cable’s ends. Tighten those ends.

6.4

Connecting the refrigerant piping

6.4.1

About connecting the refrigerant piping

Before connecting the refrigerant piping

Make sure the outdoor and indoor unit are mounted.

Typical workflow

Connecting the refrigerant piping involves:

▪ Connecting the refrigerant piping to the outdoor unit

▪ Connecting the refrigerant piping to the indoor unit

▪ Installing oil traps

▪ Insulating the refrigerant piping

▪ Keeping in mind the guidelines for:

▪ Pipe bending

▪ Flaring pipe ends

▪ Brazing

▪ Using the stop valves

6.4.2

Precautions when connecting the

refrigerant piping

INFORMATION

Also read the precautions and requirements in the

following chapters:

▪ General safety precautions

▪ Preparation

DANGER: RISK OF BURNING

CAUTION

▪ Do NOT use mineral oil on flared part.

▪ NEVER install a drier to this R410A unit to guarantee

its lifetime. The drying material may dissolve and

damage the system.

NOTICE

Take the following precautions on refrigerant piping into

account:

▪ Avoid anything but the designated refrigerant to get

mixed into the refrigerant cycle (e.g. air).

▪ Only use R410A when adding refrigerant.

▪ Only use installation tools (e.g. manifold gauge set) that

are exclusively used for R410A installations to

withstand the pressure and to prevent foreign materials

(e.g. mineral oils and moisture) from mixing into the

system.

▪ Install the piping so that the flare is NOT subjected to

mechanical stress

▪ Protect the piping as described in the following table to

prevent dirt, liquid or dust from entering the piping.

▪ Use caution when passing copper tubes through walls

(see figure below).

Unit

Installation period

Protection method

Outdoor unit

>1 month

Pinch the pipe

<1 month

Pinch or tape the pipe

Indoor unit

Regardless of the

period

INFORMATION

Do NOT open the refrigerant stop valve before checking

the refrigerant piping. When you need to charge additional

refrigerant it is recommended to open the refrigerant stop

valve after charging.