6 Installation

Installer reference guide

18

RZQG71~Y1 + RZQSG100~Y1

Split system air conditioners

4P385522-1A – 2016.10

NOTICE

Use this vacuum pump for R410A exclusively. Using the

same pump for other refrigerants may damage the pump

and the unit.

NOTICE

▪ Connect the vacuum pump to

both

the service port of

the gas stop valve and the service port of the liquid

stop valve to increase efficiency.

▪ Make sure that the gas stop valve and liquid stop valve

are firmly closed before performing the leak test or

vacuum drying.

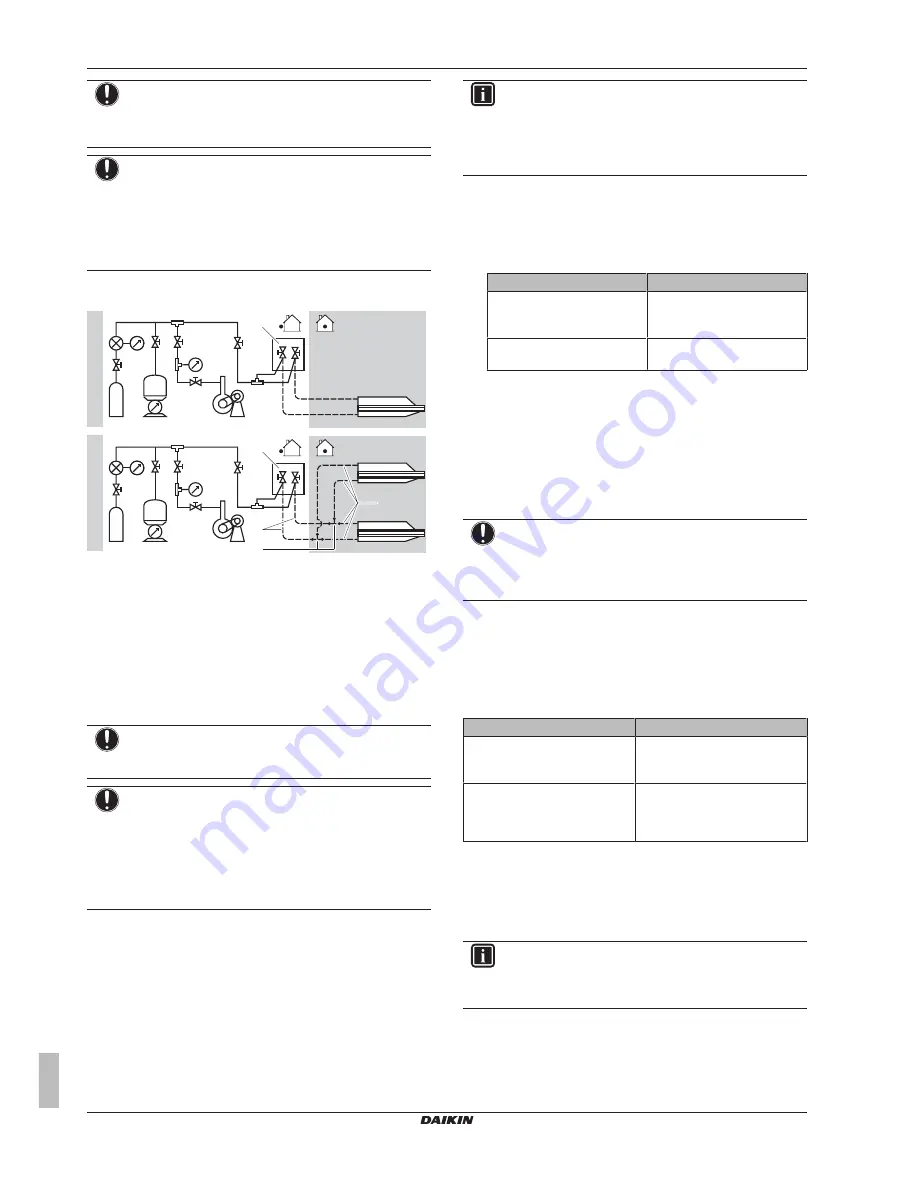

6.5.3

Checking refrigerant piping: Setup

a

c

f

c

f

b

d

e h

g

i

a

b

A

B

d

e

R410A

R410A

A

Setup in case of pair

B

Setup in case of twin

a

Pressure gauge

b

Nitrogen

c

Refrigerant

d

Weighing machine

e

Vacuum pump

f

Stop valve

g

Main piping

h

Refrigerant branch kit

i

Branch piping

6.5.4

To check for leaks

NOTICE

Do NOT exceed the unit's maximum working pressure (see

"PS High" on the unit name plate).

NOTICE

Make sure to use a recommended bubble test solution

from your wholesaler. Do not use soap water, which may

cause cracking of flare nuts (soap water may contain salt,

which absorbs moisture that will freeze when the piping

gets cold), and/or lead to corrosion of flared joints (soap

water may contain ammonia which causes a corrosive

effect between the brass flare nut and the copper flare).

1

Charge the system with nitrogen gas up to a gauge pressure of

at least 200 kPa (2 bar). It is recommended to pressurize to

3000 kPa (30 bar) in order to detect small leaks.

2

Check for leaks by applying the bubble test solution to all

connections.

3

Discharge all nitrogen gas.

INFORMATION

After opening the stop valve, it is possible that the pressure

in the refrigerant piping does NOT increase. This might be

caused by e.g. the closed state of the expansion valve in

the outdoor unit circuit, but does NOT present any problem

for correct operation of the unit.

6.5.5

To perform vacuum drying

1

Vacuum the system until the pressure on the manifold indicates

−0.1 MPa (−1 bar).

2

Leave as is for 4-5 minutes and check the pressure:

If the pressure…

Then…

Does not change

There is no moisture in the

system. This procedure is

finished.

Increases

There is moisture in the

system. Go to the next step.

3

Evacuate for at least 2 hours to a pressure on the manifold of

−0.1 MPa (−1 bar).

4

After turning OFF the pump, check the pressure for at least

1 hour.

5

If you do NOT reach the target vacuum or cannot maintain the

vacuum for 1 hour, do the following:

▪ Check for leaks again.

▪ Perform vacuum drying again.

NOTICE

Make sure to open the stop valves after installing the

refrigerant piping and performing vacuum drying. Running

the system with the stop valves closed may break the

compressor.

6.6

Charging refrigerant

6.6.1

About charging refrigerant

The outdoor unit is factory charged with refrigerant, but in some

cases the following might be necessary:

What

When

Charging additional refrigerant

When the total liquid piping

length is more than specified

(see later).

Completely recharging refrigerant

Example:

▪ When relocating the system.

▪ After a leak.

For RZQG only: When piping length is <5 m, a complete recharge of

the unit is required.

Charging additional refrigerant

Before charging additional refrigerant, make sure the outdoor unit's

external

refrigerant piping is checked (leak test, vacuum drying).

INFORMATION

Depending on the units and/or the installation conditions, it

might be necessary to connect electrical wiring before you

can charge refrigerant.

Typical workflow – Charging additional refrigerant typically consists

of the following stages:

1 Determining if and how much you have to charge additionally.

2 If necessary, charging additional refrigerant.