5 Preparation

Installer reference guide

9

RZQG71~Y1 + RZQSG100~Y1

Split system air conditioners

4P385522-1A – 2016.10

Reuse not allowed

You may not reuse existing piping in the following cases:

▪ When the compressor in the old installation had problems

(example: breakdown).

Possible consequence:

oxidised coolant

oil, scale residue and other adverse effects.

▪ When the indoor and outdoor units were disconnected from the

piping for a long time.

Possible consequence:

water and dirt in

the piping.

▪ When the copper piping is corroded.

Reuse allowed

In other cases than above, you may reuse existing piping but keep

the following in mind:

Item

Description

Piping diameter

Must comply with requirements. See

"5.3.2 Refrigerant piping requirements" on

page 9

.

Piping material

Piping length and

height difference

Piping insulation

If deteriorated, must be replaced.

Must comply with requirements. See

"5.3.3 Refrigerant piping insulation" on

page 12

.

Flare connections

May not be reused. Make new ones to

prevent leaks. See

"6.4.3 Guidelines when

connecting the refrigerant piping" on

page 15

and

"6.4.5 To flare the pipe

end" on page 15

.

Welded connections

Must be checked for gas leaks.

Cleaning pipes

If the following conditions are met, you do

not have to clean the pipes. Otherwise, you

must clean the pipes, or install new ones.

Conditions:

▪ The total one‑way piping length is <50 m.

This means:

▪ Pair: L1<50 m

▪ Twin and triple: L1+L2<50 m

▪ Double twin: L1+L2+L4<50 m

▪ You pumped down the old system

correctly. This means:

▪ Operated the unit continuously for

30 minutes in cooling mode.

▪ Pumped down the system.

▪ Removed the old units.

▪ Piping is not contaminated (see below).

To check if piping is contaminated

You must check if existing piping is contaminated because using

piping with deteriorated oil will cause compressor breakdown.

Prerequisite:

You need an oil checking reference card. This is

available from your dealer.

1

Put some residual oil from the piping on a piece of white paper.

2

Compare the colours:

If the oil colour is…

Then…

Identical to or darker than the

circled colour on the reference

card

You must clean the existing

piping, or install new piping.

Lighter than the circled colour

on the reference card

You can reuse the piping

without cleaning.

5.3.2

Refrigerant piping requirements

INFORMATION

Also read the precautions and requirements in the

"General safety precautions" chapter.

When connecting multiple indoor units to the outdoor unit, mind the

following:

Refrigerant branch kit One or more refrigerant branch kits are

required. See

"4.3.1 Possible options for the

outdoor unit" on page 7

.

Upward and

downward piping

Perform upward and downward piping only

on the main piping line (L1).

Branch pipes

▪ Install the branch pipes horizontally (with a

maximum inclination of 15°) or vertically.

▪ Make the length of the branch pipes to the

indoor units as short as possible.

▪ Try to keep length of the branch pipes to

the indoor units equal.

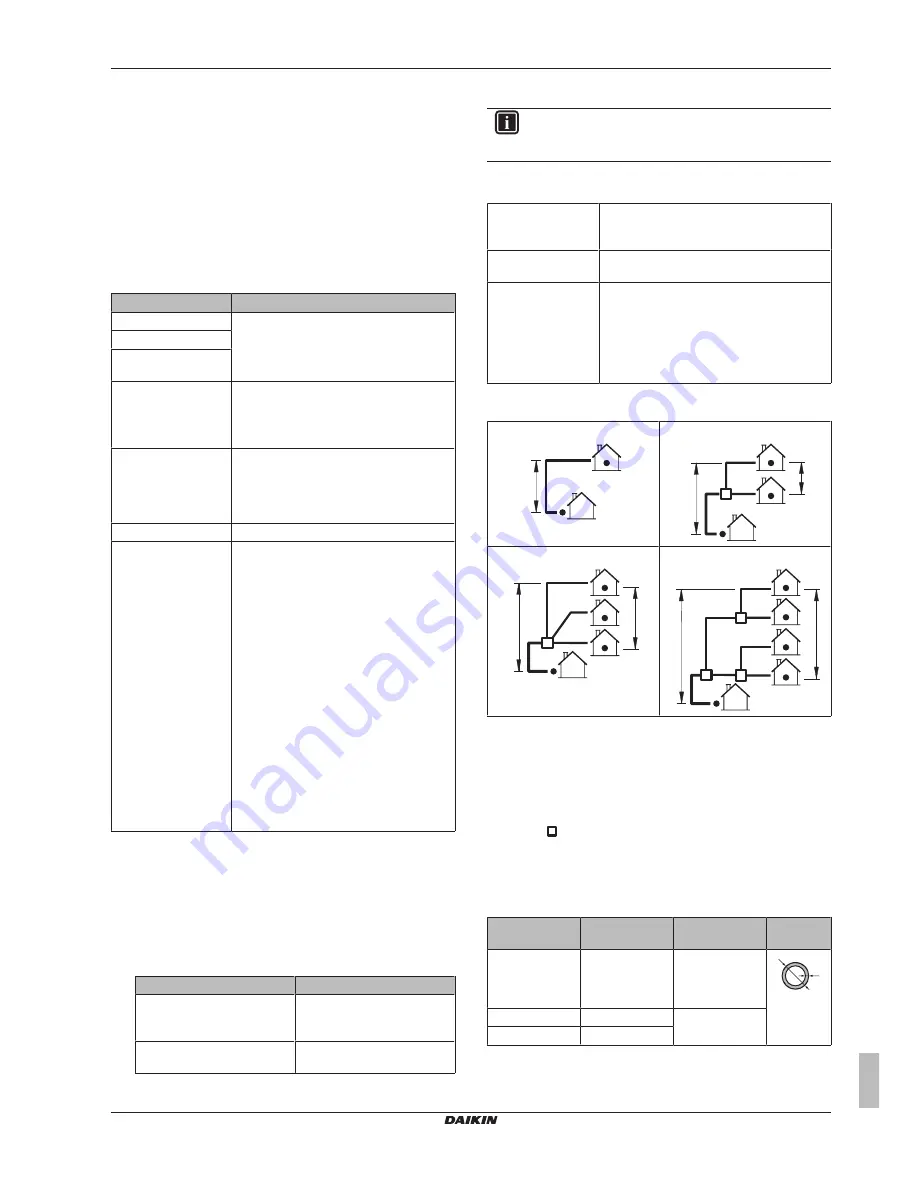

Definitions: L1~L7, H1, H2

Pair

(a)

H1

L1

Twin

(a)

H1

H2

L1

L2

L3

Triple

(a)

L2

L3

L4

H1

H2

L1

Double twin

(a)

H1

H2

L1

L2

L3

L4

L5

L6

L7

(a)

Assume that the longest line in the illustration corresponds

with the actual longest pipe, and the highest unit in the

illustration corresponds with the actual highest unit.

L1

Main piping

L2~L7

Branch piping

H1

Height difference between the highest indoor unit and the

outdoor unit

H2

Height difference between the highest and the lowest

indoor unit

Refrigerant branch kit

Refrigerant piping material

▪

Piping material:

Phosphoric acid deoxidised seamless copper.

▪

Piping temper grade and thickness:

Outer diameter

(Ø)

Temper grade

Thickness (t)

(a)

6.4 mm (1/4")

9.5 mm (3/8")

12.7 mm (1/2")

Annealed (O)

≥0.8 mm

t

Ø

15.9 mm (5/8")

Annealed (O)

≥1.0 mm

19.1 mm (3/4")

Half hard (1/2H)

(a)

Depending on the applicable legislation and the unit's

maximum working pressure (see "PS High" on the unit

name plate), larger piping thickness might be required.