5 Preparation

Installer and user reference guide

12

SERHQ020~0 SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1B – 2018.04

In places with weak reception, keep distances of 3 m or more to

avoid electromagnetic disturbance of other equipment and use

conduit tubes for power and transmission lines.

5.2.2

Installation site requirements of the

indoor unit

INFORMATION

Also read the following requirements:

▪ General installation site requirements. See the

"General safety precautions" chapter.

▪ Service space requirements. See the "Technical data"

chapter.

▪ Refrigerant

piping

requirements

(length,

height

difference). See further in this "Preparation" chapter.

▪ Provide sufficient space around the unit for servicing and air

circulation.

▪ Make sure the installation site withstands the unit's weight and

vibration.

▪ Make sure the unit is level.

▪ Select the location of the unit in such a way that the sound

generated by the unit does not disturb anyone, and the location is

selected according the applicable legislation.

▪ Take care that in the event of a water leak, water cannot cause

any damage to the installation space and surroundings.

▪ During installation, avoid the possibility that anybody can climb on

the unit or place objects on the unit.

▪ All piping lengths and distances have been taken into

consideration (see

"5.3.3 About the piping length" on page 13

).

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

▪ In places where there is machinery that emits electromagnetic

waves. Electromagnetic waves may disturb the control system,

and cause malfunction of the equipment.

▪ In places where there is a risk of fire due to the leakage of

flammable gases (example: thinner or gasoline), carbon fibre,

ignitable dust.

▪ In places where corrosive gas (example: sulphurous acid gas) is

produced. Corrosion of copper pipes or soldered parts may cause

the refrigerant to leak.

▪ In places where a mineral oil mist, spray or vapour may be

present in the atmosphere. Plastic parts may deteriorate and fall

off or cause water leakage.

NOTICE

This is a class A product. In a domestic environment this

product may cause radio interference in which case the

user may be required to take adequate measures.

CAUTION

Appliance NOT accessible to the general public, install it in

a secured area, protected from easy access.

This unit is suitable for installation in a commercial and

light industrial environment.

5.3

Preparing refrigerant piping

5.3.1

Refrigerant piping requirements

NOTICE

The refrigerant R410A requires strict cautions for keeping

the system clean, dry and tight.

▪ Clean and dry: foreign materials (including mineral oils

or moisture) should be prevented from getting mixed

into the system.

▪ Tight: R410A does not contain any chlorine, does not

destroy the ozone layer, and does not reduce earth's

protection against harmful ultraviolet radiation. R410A

can contribute slightly to the greenhouse effect if it is

released. Therefore pay special attention to check the

tightness of the installation.

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant. Use phosphoric acid deoxidised

seamless copper for refrigerant.

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30 mg/10 m.

▪ Temper grade: use piping with temper grade in function of the

pipe diameter as listed in table below.

Pipe Ø

Temper grade of piping material

≤15.9 mm

O (annealed)

≥19.1 mm

1/2H (half hard)

▪ The pipe thickness of the refrigerant piping shall comply with the

applicable legislation. The minimal pipe thickness for R410A

piping must be in accordance with the table below.

Pipe Ø

Minimal thickness t

6.4 mm/9.5 mm/12.7 mm

0.80 mm

15.9 mm

0.99 mm

19.1 mm/22.2 mm

0.80 mm

28.6 mm

0.99 mm

34.9 mm

1.21 mm

41.3 mm

1.43 mm

5.3.2

To select the piping size

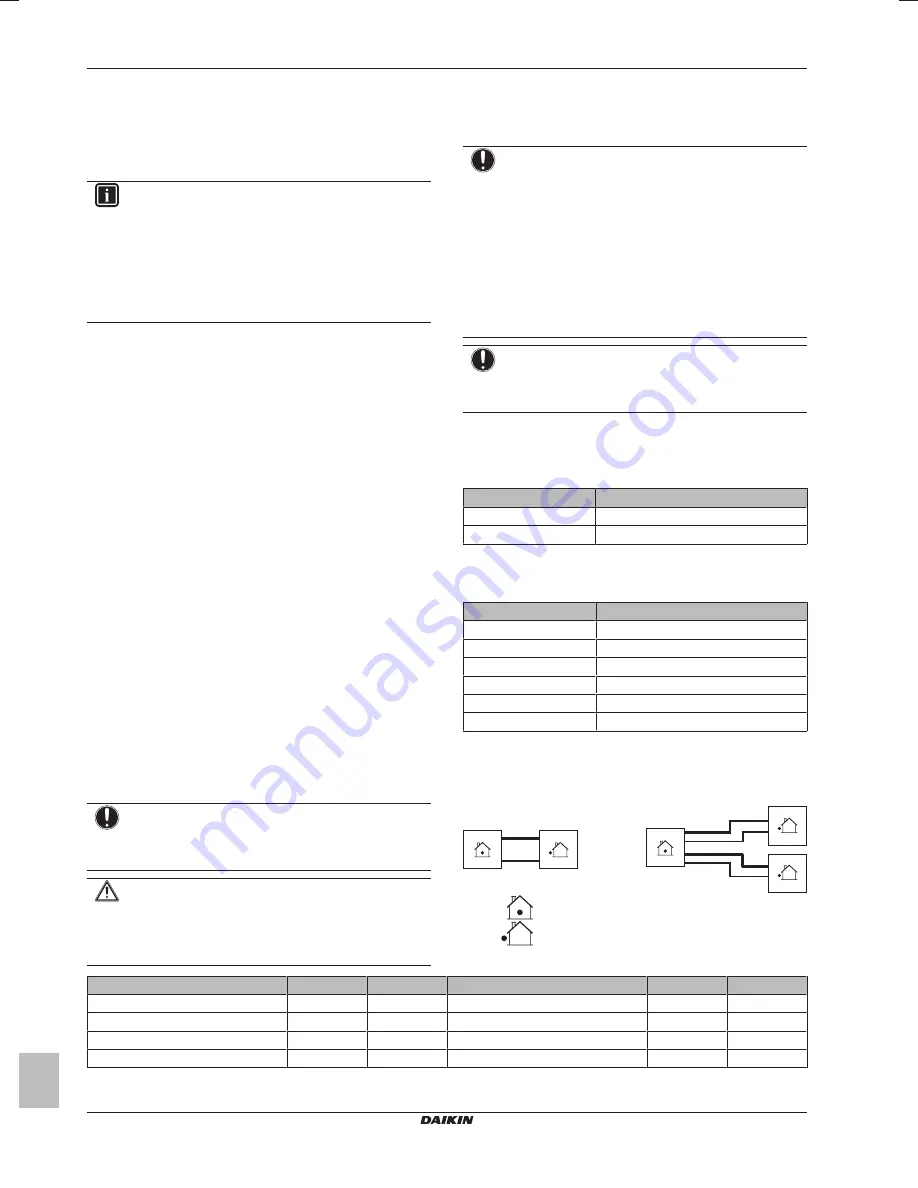

Determine the proper size using the following tables and reference

figure (only for indication).

G

L

G1

L2

G2

L1

1

2

Indoor unit

Outdoor unit

▪ Piping connection sizes

Indoor unit

Gas

Liquid

Outdoor unit

Gas

Liquid

SEHVX20BAW

Ø25.4 mm

Ø12.7 mm

1× SERHQ020BAW1

Ø22.2 mm

Ø9.52 mm

SEHVX32BAW

Ø25.4 mm

Ø12.7 mm

1× SERHQ032BAW1

Ø28.6 mm

Ø12.7 mm

SEHVX40BAW

Ø25.4 mm

Ø12.7 mm

2× SERHQ020BAW1

Ø22.2 mm

Ø9.52 mm

SEHVX64BAW

Ø25.4 mm

Ø12.7 mm

2× SERHQ032BAW1

Ø28.6 mm

Ø12.7 mm

▪ Field piping sizes