7 Configuration

Installer and user reference guide

36

SERHQ020~0 SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1B – 2018.04

After entering the field setting, the selected permission level must be

enabled by simultaneously pressing

and

, immediately

followed by simultaneously pressing

and

. Keep all 4 buttons

pressed for at least 5 seconds. Note that no indication on the user

interface is given. After the procedure the blocked buttons will not be

available anymore.

Deactivating the selected permission level is done in the same way.

[0‑01] Room temperature compensation value

If necessary, it is possible to adjust some thermistor value of the unit

by a correction value. This can be used as countermeasure for

thermistor tolerances or capacity shortage.

The compensated temperature (= measured temperature plus

compensation value) is then used to control the system and will be

displayed in the temperature read-out mode. See also field

setting [9] in this chapter for compensation values for leaving water

temperature.

[0-02]

This setting is not applicable.

[0‑03] Status

Defines whether the ON/OFF instruction can be used in the

schedule timer for space heating.

[0‑03]

Description

0

Space heating schedule timer based on ON/

OFF instruction.

1 (default)

Space heating schedule timer based on

temperature setpoint.

Space heating based on ON/OFF instruction

During operation

When the schedule timer switches space

heating OFF, the controller will be switched off

(operation LED will stop working).

Press

The schedule timer for space heating will stop

(when active at that moment) and will start

again at the next scheduled ON function.

The "last" programmed command overrules the

"preceding" programmed command and will

remain active until the "next" programmed

command occurs.

Example: imagine the actual time is 17:30 and

actions are programmed at 13:00, 16:00 and

19:00. The "last" programmed command

(16:00) overruled the "previous" programmed

command (13:00) and will remain active until

the "next" programmed command (19:00)

occurs.

So in order to know the actual setting, you

should consult the last programmed command

(this may date from the day before).

The controller is switched off (operation LED

off), but the schedule timer icon remains on.

Press

The schedule timer for space heating and the

quiet mode stops and will not start again.

The schedule timer icon is not displayed any

more.

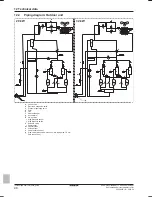

▪ Operation example: Schedule timer based on ON/OFF instruction.

When the setback function (see field setting [2]) is enabled, the

setback operation will have priority over the scheduled action in

the schedule timer if ON instruction is active. If OFF instruction is

active this will have priority over the setback function. At any time

the OFF instruction will have the highest priority.

t

18°C

40°C

40°C

18°C

A

5:00

23:00

5:00

23:00

2

B

t

9:00

16:00

19°C

19°C

22°C

21°C

42°C

42°C

45°C

44°C

19°C

19°C

22°C

21°C

42°C

42°C

45°C

44°C

1

OFF

ON

ON

6:30

0:30

B

t

6:30

9:00

16:00

23:00

19°C

19°C

22°C

21°C

42°C

42°C

45°C

44°C

19°C

19°C

22°C

21°C

42°C

42°C

45°C

44°C

3

OFF

ON

ON

18°C

40°C

40°C

18°C

1

Schedule timer

2

Setback function

3

Both setback function and schedule timer are enabled

A

Setback function

B

ON/OFF instruction

t

Time

T

Temperature setpoint

Room temperature

Leaving water temperature

Space heating based on temperature setpoint

(a)

During operation

During schedule timer operation the operation

LED is lit continuously.

Press

The schedule timer for space heating stops

and will not start again.

The controller is switched off (operation LED

off).

Press

The schedule timer for space heating and the

quiet mode stops and will not start again.

The schedule timer icon is not displayed any

more.

(a)

For leaving water temperature and/or room temperature

▪ Operation example: Schedule timer based on temperature

setpoint

When the setback function (see field setting [2]) is enabled, the

setback operation will have priority over the scheduled action in the

schedule timer.