9 Maintenance and service

Installer and user reference guide

44

SERHQ020~0 SEHVX20~64BAW

Split packaged air-cooled water chiller

4P508020-1B – 2018.04

WARNING

▪ Before carrying out any maintenance or repair activity,

ALWAYS switch off the circuit breaker on the supply

panel, remove the fuses or open the protection devices

of the unit.

▪ Do NOT touch live parts for 10 minutes after the power

supply is turned off because of high voltage risk.

▪ Please note that some sections of the electric

component box are hot.

▪ Make sure you do NOT touch a conductive section.

▪ Do NOT rinse the unit. This may cause electric shocks

or fire.

9.2.1

To prevent electrical hazards

When performing service to inverter equipment:

1

Do NOT open the electrical component box cover for 10

minutes after the power supply is turned off.

2

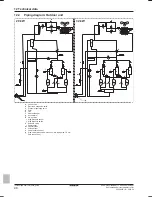

Measure the voltage between terminals on the terminal block

for power supply with a tester and confirm that the power supply

is shut off. In addition, measure points as shown in the figure,

with a tester and confirm that the voltage of the capacitor in the

main circuit is less than 50 V DC.

A1P

A3P

A2P

TP1 TP2

3

To prevent damaging the PCB, touch a non-coated metal part

to eliminate static electricity before pulling out or plugging in

connectors.

4

Pull out junction connectors X1A, X2A (X3A, X4A) for the fan

motors in the outdoor unit before starting service operation on

the inverter equipment. Be careful not to touch the live parts. (If

a fan rotates due to strong wind, it may store electricity in the

capacitor or in the main circuit and cause electric shock.)

5

After the service is finished, plug the junction connector back in.

Otherwise the malfunction code

will be displayed on the

user interface and normal operation will not be performed.

For details refer to the wiring diagram labelled on the back of the

electrical component box cover.

9.3

About service mode operation

When the vacuuming/recovery mode is used, check very carefully

what should be vacuumed/recovered before starting.

9.3.1

To use vacuum mode

1

With the unit at a standstill and setting mode 2 active, set the

required field setting (refrigerant recovery operation/vacuuming

operation) (see

"7.2.8 Mode 2: Field settings" on page 34

) to

ON (ON). Do not reset setting mode 2 until vacuuming is

finished.

Result:

The H1P LED lights up. The user interface indicates

test operation and operation is prohibited.

2

Evacuate the system with a vacuum pump.

3

Press BS1 and reset setting mode 2.

9.3.2

To recover refrigerant

This should be done by a refrigerant reclaimer. Follow the same

procedure as for vacuuming method.

1

With the unit at a standstill and setting mode 2 active, set the

required field setting (refrigerant recovery operation/vacuuming

operation) (see

"7.2.8 Mode 2: Field settings" on page 34

) to

ON (ON).

Result:

The indoor unit and the outdoor unit expansion valves

open completely and some solenoid valves are turned on. The

H1P LED lights up. The user interface indicates test operation

and operation is prohibited.

2

Cut off the power supply to the indoor units and the outdoor unit

with the circuit breaker. After the power supply of one side is cut

off, cut off the power supply of the other side within 10 minutes.

Otherwise, communication between the indoor units and the

outdoor unit may become abnormal and the expansion valves

will be completely closed again.

3

Recover the refrigerant by a refrigerant reclaimer. For details,

see the operation manual delivered with the refrigerant

reclaimer.

DANGER: RISK OF EXPLOSION

Pump down – Refrigerant leakage.

If you want to pump

down the system, and there is a leak in the refrigerant

circuit:

▪ Do NOT use the unit's automatic pump down function,

with which you can collect all refrigerant from the

system into the outdoor unit.

Possible consequence:

Self-combustion and explosion of the compressor

because of air going into the operating compressor.

▪ Use a separate recovery system so that the unit's

compressor does NOT have to operate.

NOTICE

Make sure to NOT recover any oil while recovering

refrigerant.

Example:

By using an oil separator.

9.4

Checklist for yearly maintenance

of the indoor unit

▪ Water pressure

▪ Water filter

▪ Water pressure relief valve

▪ Relief valve hose

▪ Switch box

Water pressure

Keep water pressure above 1 bar. If it is lower, add water.

Water filter

Clean the water filter.

NOTICE

Handle the water filter with care. Do NOT use excessive

force when you reinsert the water filter so as NOT to

damage the water filter mesh.

Water pressure relief valve

Turn the red knob on the valve counter-clockwise and check if it

operates correctly:

▪ If you do not hear a clacking sound, contact your local dealer.

▪ In case the water keeps running out of the unit, close both the

water inlet and outlet shut-off valves first and then contact your

local dealer.

Pressure relief valve hose

Check the condition and routing of the hose. Water must drain

appropriately from the hose.