10

English

Cut with a tube cutter

Figure 11

2.

Connect the piping.

•

Remove the upper and lower front panels.

•

Slide the front panel (lower) along the field piping

until it is far enough away that it will not be affected

by heat from the brazing, as shown in Figure 12.

•

Braze up to the field piping fitting port while cooling

the sensor and the thermal insulation.

•

Close the upper and lower front panels once heat

from the brazed areas has dissipated.

•

When brazing the field piping, cover the pipe insulation and

the thermal sensor inside the insulation with a damp cloth to

prevent any damage to the sensor or the insulation.

Otherwise, the sensor may be damaged by heat of brazing,

which leads to a failure of normal operation.

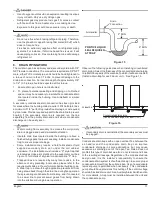

Field piping fitting port (brazed)

Field piping

Figure 12

3.

After the work is finished, make sure to check that there is

no gas leak.

4.

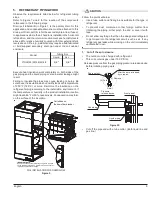

After checking for gas leaks, be sure to insulate the piping

connections referring to Fig. 13.

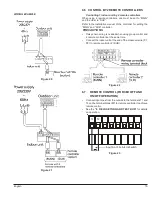

Do not leave a gap

Gas piping

Piping heat insulation

material

Liquid piping

Air

handler

Figure 13

•

Be sure to insulate any field piping all the way to the piping

connection inside the unit. Any exposed piping may cause

condensation or burns if touched.

•

When brazing the refrigerant piping, perform nitrogen

replacement first or perform the brazing while feeding

nitrogen into the refrigerant piping. (Refer to Figure 14.)

Refrigerant piping

Part to be brazed

Taping

Pressure-reducing valve

hands

valve

Nitrogen

Nitrogen

Figure 14

•

When brazing pipes while feeding nitrogen inside the piping,

make sure to set the nitrogen pressure to 2.9 PSI or less

using the pressure reducing valve.

(This pressure is such that a breeze is blown to your cheek.)

•

When brazing the refrigerant piping, perform nitrogen

replacement first or perform the brazing while feeding

nitrogen into the refrigerant piping. (Refer to Figure 14.)

•

When following the Air Tight test procedure during installation

(refer to the outdoor unit installation manual for details), only

pressurize to 450 psig (3.1MPa) when using FTQ.