Supplementary Explanation

Si-93

56

Supplementary Explanation

Unit No.

reallocation (Mode

No.45)

Unit No. before reallocation

Unit No. after reallocation

3

4

1, 6

5

4

2

(HL042)

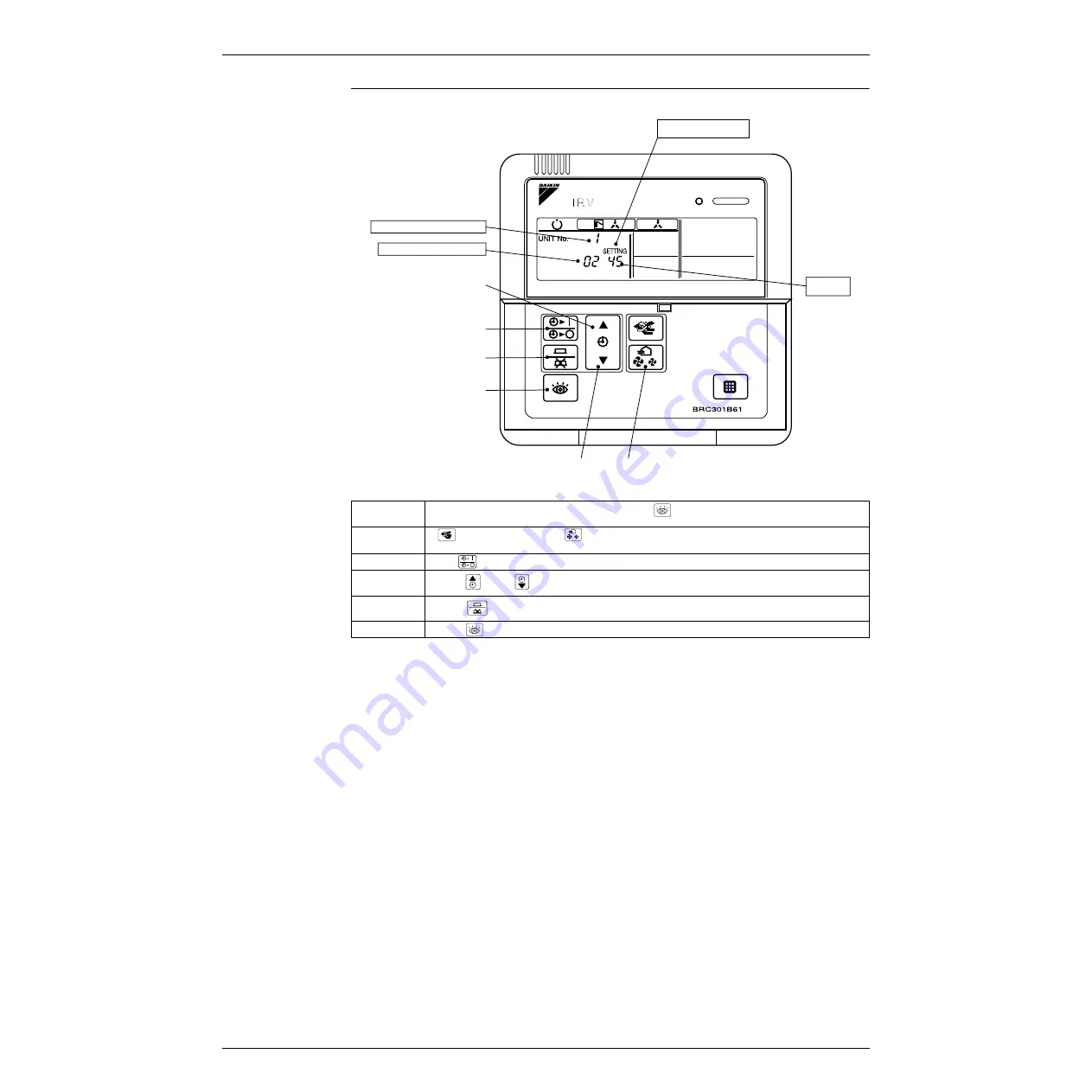

Field setting mode

Mode No.

Step 1

With equipment in field setting mode, press the

button for more than 4 seconds to enter

service mode.

Step 2

Mode No.: UP

↔

Mode No.: DOWN

Use [MODE] and [AIR VOLUME] to select mode No.45.

Step 3

Use

to select setting Unit No.

Step 4

Press

or

button to select Unit No. after reallocation.

Step 5

Press

button once to enter settings.

Step 6

Press

button to return to normal mode.

Summary of Contents for VAM 500EJ

Page 5: ...Si 93 iv Table of Contents...

Page 7: ...Introduction Si 93 vi 1 1 1 Cautions in Repair Warning...

Page 8: ...Si 93 Introduction vii...

Page 11: ...Si 93 2 General Constructions...

Page 15: ...Si 93 6 Operation...

Page 21: ...Si 93 12 Maintenance...

Page 27: ...Si 93 18 Control Functions...

Page 35: ...Si 93 26 Circuit Operations...

Page 39: ...Si 93 30 Troubleshooting...

Page 59: ...Troubleshooting Si 93 50 Troubleshooting...

Page 61: ...Si 93 52 Supplementary Explanation...

Page 72: ...Si 93 Appendix 63 Part 8 Appendix 1 Appendix 65 1 1 Wiring Diagram 65...

Page 73: ...Si 93 64 Appendix...

Page 74: ...Si 93 Appendix Appendix 65 1 Appendix 1 1 Wiring Diagram VAM500EJVE VAM800EJVE VAM1000EJVE...

Page 75: ...Appendix Si 93 66 Appendix VAM2000EJVE...

Page 79: ...Si 93 iv Index...