Installation Manual

EDMMT712101

134

VAM-HVE/HVLT Series

3P645058-1

12

English

FI

E

LD

S

E

TTING

AND

T

E

ST

RUN

7

7-1

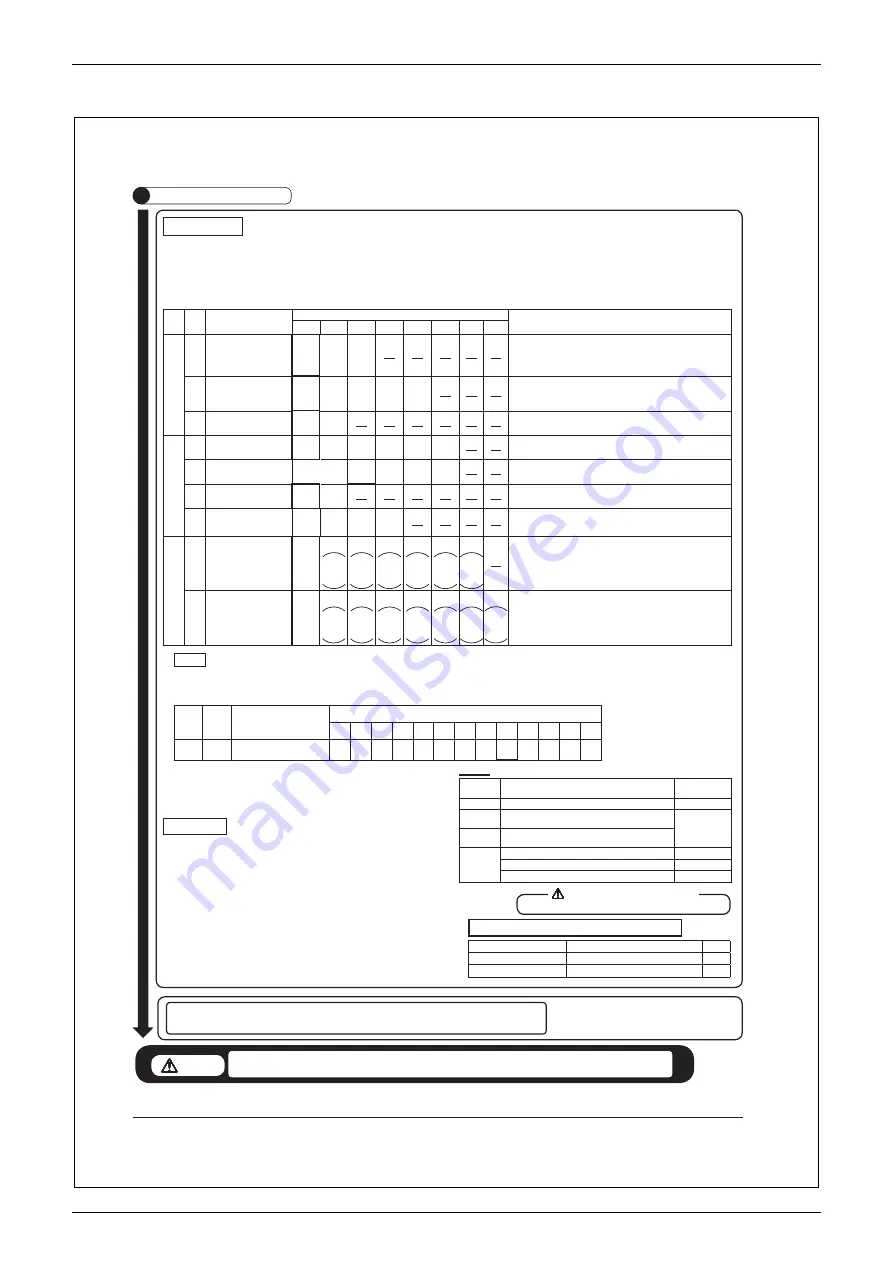

Field

Settings

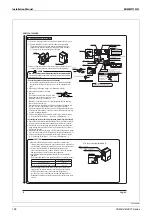

(1) Make sure the electrical component box is closed before turning on the power.

(2) Depending on the type of installation, make the field settings from the remote controller following the “Field Settings” section of the installation manual which came with the remote controller.

y

When a change is made to the settings of [Filter contamination setting], [Night time free cooling operation starting time], or [24-hour ventilation setting], provide your customer the information

described in the Remarks of the table below.

y

Setting is made by changing the three numbers: “mode number”, “setting switch number”, and “setting position number”.

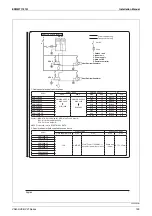

Descriptions of settings and setting numbers (For other settings, refer to the general catalog.)

Mode

No.

Setting

s

w

itch

No.

Setting

descriptions

Setting

position

No.

Remarks

01

02

03

04

05

06

07

08

17

(27)

0

Fresh-up

(Setting of more supply air/more

exhaust air)

Accumulated

2500 hours

Accumulated

1250 hours

No

accumulation

The factory setting for the fi lter sign display time is 2500 hours (equivalent to 1 year). However, if the unit is installed

in a location subjected to dust and particles, the display time can be shortened to allow the fi lter to be cleaned more

frequently.

If the setting position “03” is selected, the fi lter sign will not be displayed. However, advise the customer that the fi lter

needs to be cleaned regularly to prevent clogging.

1

Nighttime free cooling operation

starting time (after the operation stops)

OFF

ON /

2 hours later

ON /

4 hours later

ON /

6 hours later

ON /

8 hours later

The factory default setting for nighttime free cleaning operation is “OFF”. However, nighttime free cleaning operation

can be set to “ON” by selecting one of the setting position numbers “02” to “05”.

During night nighttime free cleaning operation, the operation indicator lamp on the remote control is off. If the nighttime

free cleaning setting is set to “ON”, please explain this to your customer.

4

Initial setting for ventilation fan

Normal

Ultra high

The factory default setting is the setting position number “01” (the unit operates at a “high” notch when the ventilation

rate displayed on the remote control is “high”). By selecting the setting position number “02”, the unit operates at the

“ultra-high” notch when the ventilation rate displayed on the remote control is “high”.

18

(28)

0

External input setting (J2-JC)

Last command

Priority on

external input

Priority on

operation

Forced OFF

Sync with fan

Ú

24-hour

ventilation

ON/OFF

Selecting the setting position number “04” allows forced OFF by an external input.

Selecting the setting position number “06” cancels 24-hour ventilation operation by an external input.

3

Main unit X3M

External contact output changeover

(X1-X2)

Humidifi cation operation output

Fan operation

(Damper output)

Abnormal

output

Filter sign

Output

7

Fresh-up

(Setting of more supply air/more

exhaust air)

Supply air

Exhaust air

The factory default setting is the setting position number “01”: “Supply” Fresh-Up.

Exhaust” Fresh-Up can be set by selecting the setting position number “02”.

11

Main unit X3M

External contact output changeover

(X3-X4)

Fan operation

(Damper output)

Abnormal

output

Filter sign

output

Operation

output

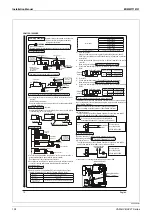

19

(29)

1

Intermittent low tap operation setting

NO

Ventilation

rate 1/15

Fan OFF for 28

minutes

Fan ON for 2

minutes

Ventilation

rate 1/10

Fan OFF for 27

minutes

Fan ON for 3

minutes

Ventilation

rate1/6

Fan OFF for 25

minutes

Fan ON for 5

minutes

Ventilation

rate 1/4

Fan OFF for 22.5

minutes

Fan ON for 7.5

minutes

Ventilation

rate 1/3

Fan OFF for 20

minutes

Fan ON for 10

minutes

Ventilation

rate 1/2

Fan OFF for 15

minutes

Fan ON for 15

minutes

The factory default setting for intermittent low tap operation setting is “OFF”.

The intermittent low tap operation setting can be changed to “ON” by selecting a setting position number.

4

24-hour ventilation setting

NO

Ventilation

rate 1/15

Fan OFF for 28

minutes

Fan ON for 2

minutes

Ventilation

rate 1/10

Fan OFF for 27

minutes

Fan ON for 3

minutes

Ventilation

rate 1/6

Fan OFF for 25

minutes

Fan ON for 5

minutes

Ventilation

rate 1/4

Fan OFF for

22.5 minutes

Fan ON for 7.5

minutes

Ventilation

rate 1/3

Fan OFF for 20

minutes

Fan ON for 10

minutes

Ventilation

rate 1/2

Fan OFF for

15 minute

Fan ON for 15

minutes

Ventilation

rate 1/1

Continuous

opera

The factory default setting for 24-hour ventilation operation setting is “OFF”. 24-hour ventilation operation can be set to

“ON” by selecting one of the setting position numbers “02” – “08”.

During 24-hour ventilation operation, the operation indicator lamp on the remote control is off.

If the 24-hour ventilation setting is set to “ON”, please explain this to your customer.

Disconnect the power supply before changing the wiring or making switch settings.

CAUTION

E

L

E

CTRIC

SHOCK

RISK

Table

1

Remote controller

display

n

e

k

at

e

b

ot

s

e

r

u

s

a

e

M

kr

o

w

g

ni

ri

w

r

o

n

oi

ta

ll

at

s

ni

n

i

m

el

b

o

r

P

61

t

Error in supply voltage “220-240V”

t

Supply voltage

U5

t

Incorrect setting of “MAIN/SUB” remote controller (two MAIN remote

controllers are connected)

t

Correct

U8

t

Incorrect setting of “MAIN/SUB” remote controller (two SUB remote controllers

are connected)

No display

t

Power supply construction work is not done for the total heat exchanger unit

t

Reset

t

Power of the total heat exchanger unit is not turned on

t

Turn on the power

t

Wrong remote controller wiring or disconnected wires

t

Correct the wiring

Items to be checked

If not properly done, what is likely to occur

Check

Have you performed a test run

The unit may not operate

Was air taken into each intake?

Ventilation rate is insuffi cient, or noise may occur

7-3

Items

to

be

checked

after

completion

of

test

run

7-2

Test

Run

y

Make sure that all electric wiring works and duct connections have been completed.

(In particular, if a closing damper is installed in the middle of the duct, make sure that it is open.)

y

Make sure the electrical component box of the unit is closed before turning on the power.

y

Perform a test run following the operation manual and make sure that the unit operates properly.

Check the airflow from each outlet and intake, and if the airflow appears weak, check if the fan is rotating.

“Measures in the event of abnormal completion”

y

Blinking operation indicator lamp on the remote controller indicates an error. Confirm the error code on the

LCD and check for errors/problems.

Error codes and error descriptions are described in the “Operation Manual” provided.

y

In particular, if the display shows any of the conditions listed in Table 1, it may be due to faulty installation

or wiring work, or the power may not be turned on.

y

The factory default setting position is displayed in the frame.

y

The settings are applied to the entire group, but if the mode number inside the parentheses is

selected, the setting can be applied to individual units.

(3) When selecting the single nighttime free cooling operation, make the field setting as follows:

Units

Setting

s

w

itch

No.

Setting

descriptions

Setting

position

No.

01

02

03

04

05

06

07

08

09

10

11

12

13

17

(27)

7

Target temperature for single

nighttime free cooling

18°C 19°C 20°C 21°C 22°C 23°C 24°C 25°C 26°C 27°C 28°C 29°C 30°C

y

The factory default setting for target temperature for single nighttime free cooling is “26°C”. Target

temperature for single nighttime free cooling can be changed by selecting one of the setting

position numbers.

y

Refer to engineering data for details on field settings.

y

Before handing over the unit to the customer after the test run, make sure that the electrical component box, heat exchange element, and air

filter are installed in their proper positions and that the maintenance cover and electrical component box are attached.

CAUTION

y

If an error code other than those in Table 1 is displayed, refer to engineering data or operation manual.

Fix the problem and perform a test run again.

Summary of Contents for VAM Series

Page 2: ......

Page 4: ...EDMMT712101 2 Table of Contents 17 6 Precautions for Design and Installation 181 ...

Page 56: ...Control System EDMMT712101 54 VAM HVE HVLT Series C 3P343420 1E ...

Page 138: ...Installation Manual EDMMT712101 136 VAM HVE HVLT Series 3P607378 3C ...

Page 139: ...EDMMT712101 Installation Manual VAM HVE HVLT Series 137 3P607378 3C ...

Page 141: ...EDMMT712101 Installation Manual VAM HVE HVLT Series 139 C EM20A032 ...

Page 142: ...Installation Manual EDMMT712101 140 VAM HVE HVLT Series C EM20A032 ...

Page 143: ...EDMMT712101 Installation Manual VAM HVE HVLT Series 141 C EM20A032 ...

Page 147: ...EDMMT712101 Details of Optional Accessories VAM HVE HVLT Series 145 3P607378 3C ...

Page 148: ...Details of Optional Accessories EDMMT712101 146 VAM HVE HVLT Series 3P607378 3C ...

Page 149: ...EDMMT712101 Details of Optional Accessories VAM HVE HVLT Series 147 3P607378 3C ...

Page 150: ...Details of Optional Accessories EDMMT712101 148 VAM HVE HVLT Series 3P607378 3C ...

Page 151: ...EDMMT712101 Details of Optional Accessories VAM HVE HVLT Series 149 3P607378 3C ...

Page 152: ...Details of Optional Accessories EDMMT712101 150 VAM HVE HVLT Series 3P607378 3C ...

Page 155: ...EDMMT712101 Details of Optional Accessories VAM HVE HVLT Series 153 4P457318 1D ...

Page 156: ...Details of Optional Accessories EDMMT712101 154 VAM HVE HVLT Series 4P457318 1D ...

Page 157: ...EDMMT712101 Details of Optional Accessories VAM HVE HVLT Series 155 4P457318 1D ...

Page 158: ...Details of Optional Accessories EDMMT712101 156 VAM HVE HVLT Series 4P457318 1D ...

Page 159: ...EDMMT712101 Details of Optional Accessories VAM HVE HVLT Series 157 4P457318 1D ...

Page 184: ......

Page 185: ......

Page 186: ......

Page 187: ......