Product Introduction

EDMMT712101

4

VAM-HVE/HVLT Series

By positive pressure in the room, the entering of dirty

outside air, odors and moisture when opening and closing

of doorway is prevented.

By changing the airflow balance, positive pressure

or negative pressure in a room can be achieved

in order to prevent pollutants from entering or

flowing out.

By negative pressure in the room, contaminated

air and moisture from the room is prevented from

leaking into other areas.

Example: Convenience Stores

Example: Conference Room

Supply fresh up operation increases the

supply air volume to prevent pollutants

from entering into the room.

For example, it keeps outdoor pollen and dust from

entering when doors are opened or closed, or

through gaps in windows.

Exhaust fresh up operation will increase

exhaust air volume to prevent pollutants

from flowing to other area.

For example, to prevent dirty air generated indoors

from flowing out in through windows and doors, the

indoor air is kept under negative pressure and

discharged.

Dust

Doorway

SA

EA

EA

SA

hallway

Positive

pr)

Negative

pressure(-)

A i r f l o w C o n t r o l

F r e s h u p O p e r a t i o n

Class 1 Ventilation

Class 2 Ventilation

Class 3 Ventilation

Both supply air and exhaust

air are controlled by mechanical

ventilation in order to achieve

stable ventilation when required.

For common ventilation usage,

Class 1 ventilation is able to meet

the requirement.

System that uses mechanical

ventilation for supply air and

natural ventilation for exhaust air.

Class 2 ventilation is often used for

specific purpose such as positively

pressured room (Hospital Clean Room,

Factory Clean Room).

System that uses natural ventilation

for supply air and mechanical

ventilation for exhaust air.

Class 3 ventilation often being used

at area with high odor generation

such as kitchen and toilet.

“For example:

Heat Reclaim Ventilator”

“For example:

Mechanical Ventilation (Supply)”

“For example:

Mechanical Ventilation (Exhaust)”

SA

EA

For example:

Mechanical Ventilation (Supply)”

Dust

Positive

pr)

Negative

pressure(-)

k i t c h e n

Summary of Contents for VAM Series

Page 2: ......

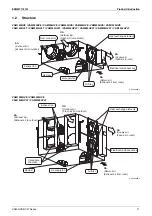

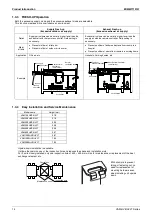

Page 4: ...EDMMT712101 2 Table of Contents 17 6 Precautions for Design and Installation 181 ...

Page 56: ...Control System EDMMT712101 54 VAM HVE HVLT Series C 3P343420 1E ...

Page 138: ...Installation Manual EDMMT712101 136 VAM HVE HVLT Series 3P607378 3C ...

Page 139: ...EDMMT712101 Installation Manual VAM HVE HVLT Series 137 3P607378 3C ...

Page 141: ...EDMMT712101 Installation Manual VAM HVE HVLT Series 139 C EM20A032 ...

Page 142: ...Installation Manual EDMMT712101 140 VAM HVE HVLT Series C EM20A032 ...

Page 143: ...EDMMT712101 Installation Manual VAM HVE HVLT Series 141 C EM20A032 ...

Page 147: ...EDMMT712101 Details of Optional Accessories VAM HVE HVLT Series 145 3P607378 3C ...

Page 148: ...Details of Optional Accessories EDMMT712101 146 VAM HVE HVLT Series 3P607378 3C ...

Page 149: ...EDMMT712101 Details of Optional Accessories VAM HVE HVLT Series 147 3P607378 3C ...

Page 150: ...Details of Optional Accessories EDMMT712101 148 VAM HVE HVLT Series 3P607378 3C ...

Page 151: ...EDMMT712101 Details of Optional Accessories VAM HVE HVLT Series 149 3P607378 3C ...

Page 152: ...Details of Optional Accessories EDMMT712101 150 VAM HVE HVLT Series 3P607378 3C ...

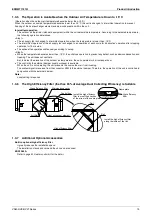

Page 155: ...EDMMT712101 Details of Optional Accessories VAM HVE HVLT Series 153 4P457318 1D ...

Page 156: ...Details of Optional Accessories EDMMT712101 154 VAM HVE HVLT Series 4P457318 1D ...

Page 157: ...EDMMT712101 Details of Optional Accessories VAM HVE HVLT Series 155 4P457318 1D ...

Page 158: ...Details of Optional Accessories EDMMT712101 156 VAM HVE HVLT Series 4P457318 1D ...

Page 159: ...EDMMT712101 Details of Optional Accessories VAM HVE HVLT Series 157 4P457318 1D ...

Page 184: ......

Page 185: ......

Page 186: ......

Page 187: ......