18

|

Piping installation

Installer and user reference guide

81

REMA5+REYA8~20A7Y1B

VRV 5 heat recovery

4P687640-1 – 2022.07

▪

Flare connections:

Only use annealed material.

▪

Piping temper grade and thickness:

Outer diameter (Ø)

Temper grade

Thickness (t)

(a)

6.4 mm (1/4")

9.5 mm (3/8")

12.7 mm (1/2")

Annealed (O)

≥0.80 mm

t

Ø

15.9 mm (5/8")

Annealed (O)

≥0.99 mm

19.1 mm (3/4")

22.2 mm (7/8")

Half hard (1/2H)

≥0.80 mm

28.6 mm (1 1/8")

Half hard (1/2H)

≥0.99 mm

(a)

Depending on the applicable legislation and the maximum working pressure of the unit

(see "PS High" on the unit name plate), larger piping thickness might be required.

18.1.3 Refrigerant piping insulation

▪

Use polyethylene foam as insulation material:

-

with a heat transfer rate between 0.041 and 0.052 W/mK (0.035 and

0.045 kcal/mh°C)

-

with a heat resistance of at least 120°C

▪

Insulation thickness

Ambient temperature

Humidity

Minimum thickness

≤30°C

75% to 80% RH

15 mm

>30°C

≥80% RH

20 mm

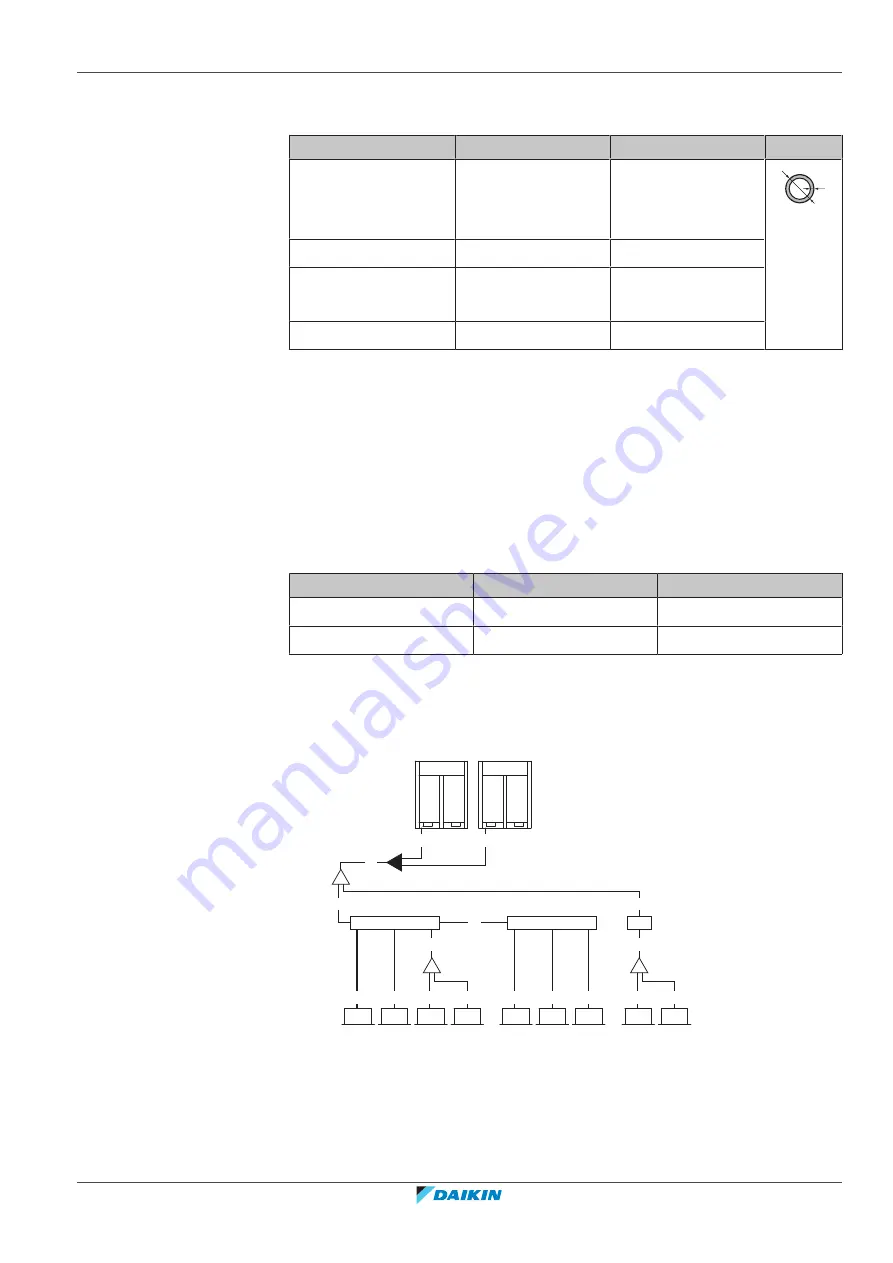

18.1.4 To select the piping size

Determine the proper size using the following tables and reference figure (only for

indication).

B

A

B

c

e

C

C

D

D

d

b

3

a

8

a

9

D

D

d

a

3

a

4

a

1

a

2

C'

D

D

C''

C

b

1

a

5

a

6

D

a

7

D

D

b

2

a1~a9

VRV DX indoor units

b1~b3

Branch selector units (BS)

c

First indoor branch kit (refnet)

d

Indoor branch kit (refnet)

e

Outdoor multi connection kit

A~D

Piping