15 Piping installation

Installation and operation manual

29

REMA5+REYA8~20A7Y1B

VRV 5 heat recovery

4P684060-1 – 2022.02

15.1

Preparing refrigerant piping

15.1.1

Refrigerant piping requirements

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant. Use phosphoric acid deoxidised

seamless copper for refrigerant.

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30 mg/10 m.

15.1.2

Refrigerant piping material

▪

Piping material:

Phosphoric acid deoxidised seamless copper.

▪

Flare connections:

Only use annealed material.

▪

Piping temper grade and thickness:

Outer diameter

(Ø)

Temper grade

Thickness (t)

(a)

6.4 mm (1/4")

9.5 mm (3/8")

12.7 mm (1/2")

Annealed (O)

≥0.80 mm

t

Ø

15.9 mm (5/8")

Annealed (O)

≥0.99 mm

19.1 mm (3/4")

22.2 mm (7/8")

Half hard (1/2H)

≥0.80 mm

28.6 mm (1 1/8")

Half hard (1/2H)

≥0.99 mm

(a)

Depending on the applicable legislation and the maximum

working pressure of the unit (see "PS High" on the unit name

plate), larger piping thickness might be required.

15.1.3

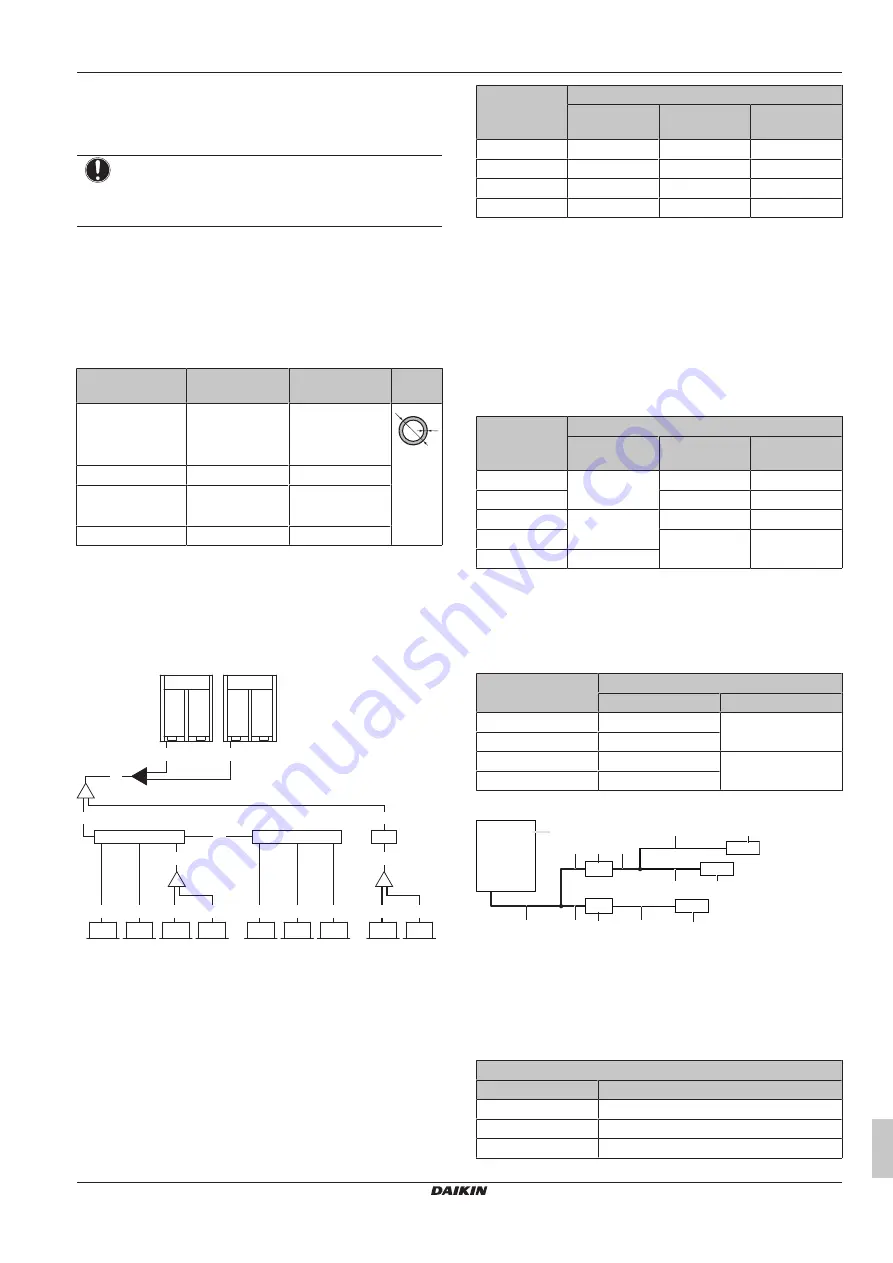

To select the piping size

Determine the proper size using the following tables and reference

figure (only for indication).

B

A

B

c

e

C

C

D

D

d

b

3

a

8

a

9

D

D

d

a

3

a

4

a

1

a

2

C'

D

D

C''

C

b

1

a

5

a

6

D

a

7

D

D

b

2

a1~a9

VRV DX indoor units

b1~b3

Branch selector units (BS)

c

First indoor branch kit (refnet)

d

Indoor branch kit (refnet)

e

Outdoor multi connection kit

A~D

Piping

A, B: Piping between outdoor unit and (first)

refrigerant branch kit

Choose from the following table in accordance with the outdoor unit

total capacity type. Pipe A is in case of multi-connection the sum of

the outdoor units connected upstream.

HP class

Piping outer diameter [mm]

Liquid pipe

Suction gas

pipe

HP/LP gas

pipe

5~10

9.5

19.1

15.9

12~18

12.7

22.2

19.1

20~24

12.7

28.6

22.2

26~28

15.9

28.6

22.2

C: Piping between refrigerant branch kits, BS

units, or refrigerant branch kits and BS units

Choose from the following table in accordance with the indoor unit

total capacity type, connected downstream. Do not let the

connection piping exceed the refrigerant piping size chosen by the

general system model name.

Example:

▪ Downstream

capacity

for

C'=[capacity

index

of

unit a1]+[unit a2]+[unit a3]+[unit a4]+[unit a5]+[unit a6]+[unit a7]

▪ Downstream capacity for C''=[capacity index of unit a3]+[unit a4]

Indoor unit

capacity index

Piping outer diameter [mm]

Liquid pipe

Suction gas

pipe

HP/LP gas

pipe

<150

9.5

15.9

12.7

150≤x<290

19.1

15.9

290≤x<450

12.7

22.2

19.1

450≤x<620

28.6

22.2

≥620

15.9

D: Piping between refrigerant branch kit or BS unit

and indoor unit

Pipe size for direct connection to indoor unit must be the same as

the connection size of the indoor unit (in case indoor unit is VRV DX

indoor).

Indoor unit capacity

index

Piping outer diameter [mm]

Gas pipe

Liquid pipe

10~32

9.5

6.4

40~80

12.7

100~140

15.9

9.5

200~250

19.1

▪ If a size-up of the piping is required, refer to the table below.

e

e

e

h

g

g

g

h

h

b

d

c

a

f

f

a

Outdoor unit

b

Main pipes (increase size)

c

First refrigerant branch kit

d

Last refrigerant branch kit

e

Indoor unit

f

BS unit

g

Piping between first and last refrigerant branch kit

(increase size)

h

Piping between last refrigerant branch kit and indoor unit

Size up

HP class

Liquid piping outer diameter [mm]

5~10

9.5

→

12.7

12~24

12.7

→

15.9

26~28

15.9

→

19.1