22 Technical data

Installation and operation manual

54

REMA5+REYA8~20A7Y1B

VRV 5 heat recovery

4P684060-1 – 2022.02

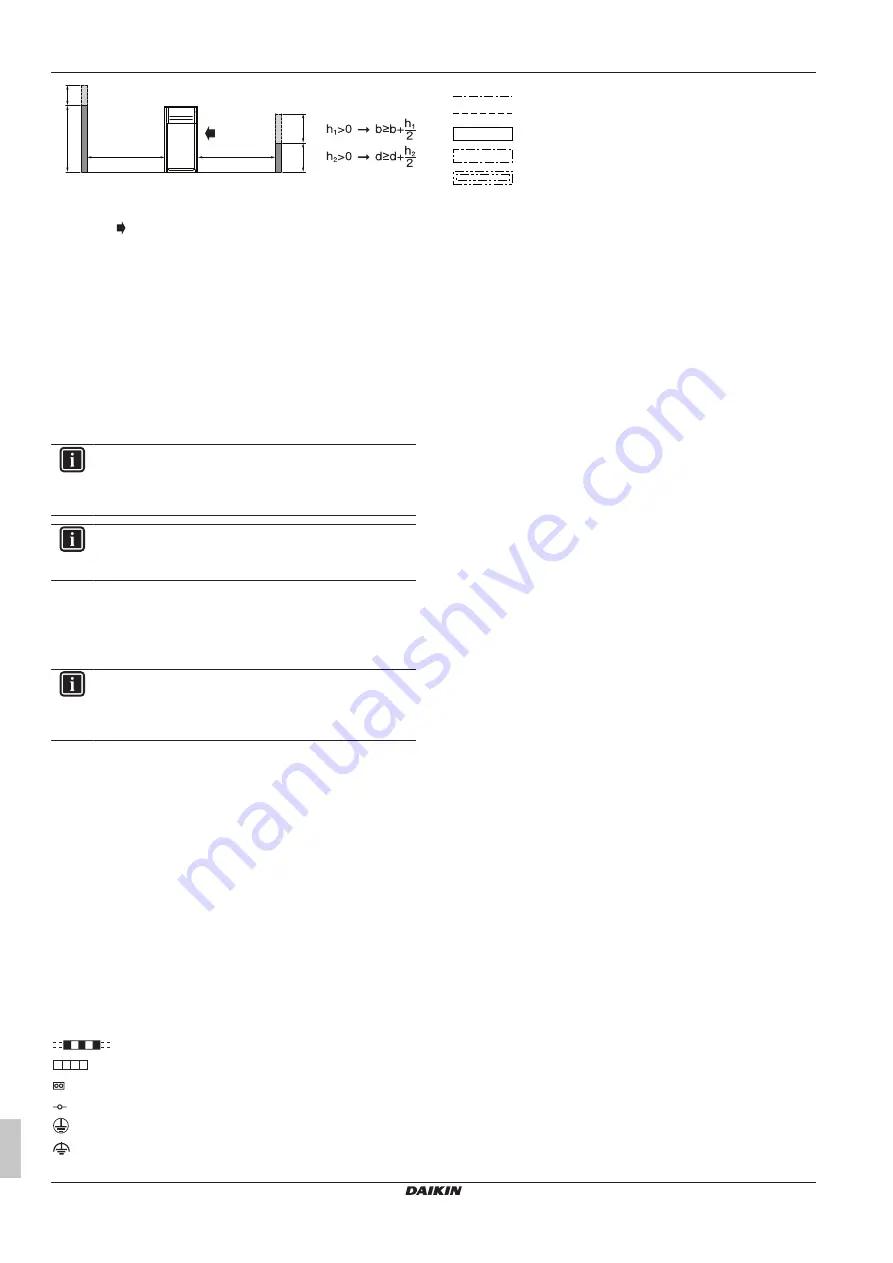

h

1

h

2

1500

500

F

(mm)

d

b

ABCD

Sides along the installation site with obstacles

F

Front side

Suction side

▪ In case of an installation site where sides A+B+C+D have

obstacles, the wall heights of sides A+C have no impact on

service space dimensions. Refer to the figure above for impact of

wall heights of sides B+D on service space dimensions.

▪ In case of an installation site where only the sides A+B have

obstacles, the wall heights have no influence on any indicated

service space dimensions.

▪ The installation space required on these drawings are for full load

heating operation without considering possible ice accumulation. If

the location of the installation is in a cold climate, then all

dimensions above should be >500 mm to avoid accumulation of

ice in between the outdoor units.

INFORMATION

The service space dimensions in above figure are based

on cooling operation at 35°C ambient temperature

(standard conditions).

INFORMATION

Further specifications can be found in the technical

engineering data.

22.2

Wiring diagram: Outdoor unit

Refer to the wiring diagram sticker on the unit. The abbreviations

used are listed below:

INFORMATION

The wiring diagram on the outdoor unit is only for the

outdoor unit. For the indoor unit or optional electrical

components, refer to the wiring diagram of the indoor unit.

1

Symbols (see below).

2

Refer to the installation or service manual on how to use

BS1~BS3 push buttons and DS1~DS2 switches.

3

Do NOT operate the unit by short-circuiting protection device

S1PH.

4

Refer to the installation manual for connection wiring to

indoor–outdoor transmission F1‑F2 and outdoor‑multi

transmission Q1‑Q2.

5

When using the central control system, connect outdoor–

outdoor transmission F1‑F2.

6

The capacity of the contact is 220~240V AC – 0.5 A (rush

current needs 3 A or less).

7

Use dry contact for micro current (10 mA or less, 15 V DC).

8

When using the optional adapter, refer to the installation

manual of the optional adapter.

Symbols:

Field wiring

Terminal block

Connector

Terminal

Protective earth

Noiseless earth

Earth wiring

Field supply

PCB

Switch box

Option

Colours:

BLK

Black

RED

Red

BLU

Blue

WHT

White

GRN

Green

Legend for wiring diagram

A1P

Printed circuit board (main)

A2P

Printed circuit board (noise filter)

A3P

Printed circuit board (inverter)

A4P

Printed circuit board (fan)

A5P (14~20 HP

only)

Printed circuit board (fan)

A6P (14~20 HP

only)

Printed circuit board (sub)

BS1~BS3 (A1P) Push button switch (MODE, SET, RETURN)

DS1, DS2

(A1P)

DIP switch

E1HC

Crankcase heater

E3H

Bottom plate heater

F1U (A1P)

Fuse (T 10 A / 250 V)

F1U (A6P)

(14~20 HP

only)

Fuse (T 3.15 A / 250 V)

F1U, F2U

Fuse (T 1 A / 250 V)

F3U

Field fuse

F101U (A4P)

Fuse

HAP (A*P)

Pilot lamp (service monitor is green)

K*R (A*P)

Relay on PCB

L1R

Reactor

M1C

Motor (compressor)

M1F

Motor (fan)

M2F (14~20 HP

only)

Motor (fan)

Q1DI

Earth leakage circuit breaker

R1T

Thermistor (air)

R3T

Thermistor (liquid, main)

R4T

Thermistor (heat exchanger, liquid pipe upper)

R5T

Thermistor (heat exchanger, liquid pipe lower)

R6T

Thermistor (subcool heat exchanger gas)

R7T

Thermistor (subcool heat exchanger liquid)

R8T

Thermistor (heat exchanger, gas upper)

R9T

Thermistor (heat exchanger, gas lower)

R10T

Thermistor (suction)

R11T

Thermistor (heat exchanger, de-icer)

R12T

Thermistor (suction compressor)

R13T

Thermistor (receiver gas)

R15T

Thermistor (M1C body)

R16T (5~12 HP

only)

Thermistor (gas injection)