13 Unit installation

Installation and operation manual

27

SV1ASV4~8A14AJV1B

VRV 5 safety valve unit

4P709466-1 – 2023.09

13.4.3

To install the drain piping

1

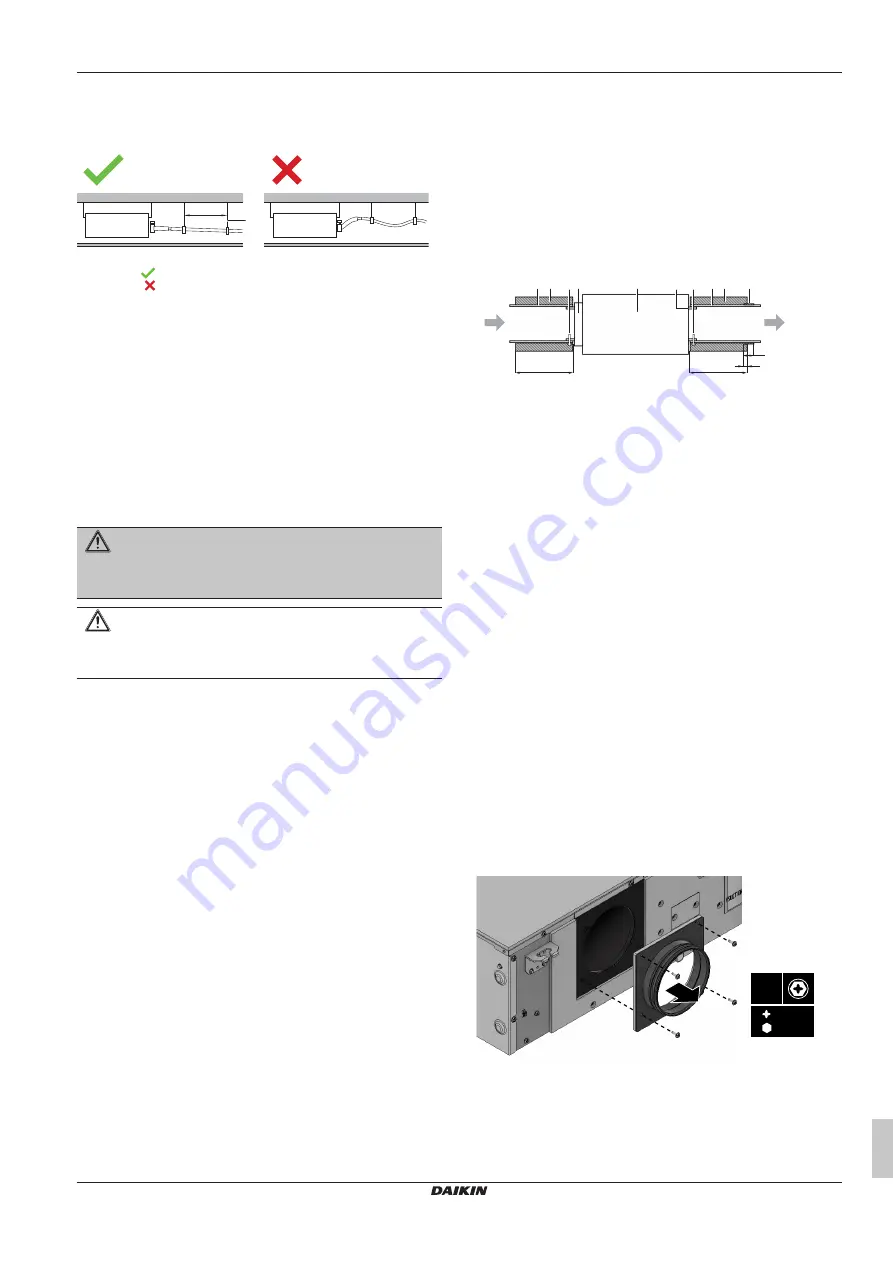

Install the drain piping with hanging bars as shown in the

illustration.

1~1.5 m

a

a

Hanging bar

Allowed

Not allowed

2

Provide a downwards slope (at least 1/100) to prevent air from

being trapped in the piping. If unable to provide an adequate

slope for the drain, use the drain up kit (K-KDU303KVE).

3

Insulate the complete drain piping in the building to prevent

condensation.

13.5

Installing the ventilation ducting

13.5.1

To install the ducting

The ducting is field supplied.

Ducting is only necessary in case the safety measures require a

ventilated enclosure. See

WARNING

Do NOT install operating ignition sources (example: open

flames, an operating gas appliance or an operating electric

heater) in the ductwork.

CAUTION

If the metal duct passes through a metal lath, wire lath or

metal plate of the wooden structure, separate the duct and

wall electrically.

1

Connect the air outlet.

▪ Position a 160 mm duct of at least 1 m over the unit duct

connection.

▪ Fix the duct to the duct connection with minimum 3 screws.

▪ Follow the instructions of the duct manufacturer for other

connections.

▪ Install the first meter of the air outlet duct after the unit in

such a way that it does not slope downward.

▪ Make sure the connections to the unit or any other

connections in the system do not leak air.

2

In case of series configuration: connect the air inlet.

▪ Install option kit EKBSDCK onto the damper. See

Possible options for the SV unit"

13].

▪ Position a 160 mm duct over the option kit.

▪ Fix the duct to the option kit with minimum 3 screws.

▪ Follow the instructions of the duct manufacturer for other

connections.

▪ Make sure the connections to the unit or any other

connections in the system do not leak air.

3

Insulate the ducting with field supply thermal insulation and with

the accessory sealing material (against condensation drops).

▪ Insulate at least the first meter of ducting against thermal

losses with glass wool or polyethylene foam (field supply)

with a minimum thickness according to the expected

ambient conditions. See

31].

▪ If both sides of the unit have ducting, insulate both sides.

▪ Install the accessory sealing material at the end of the field

supply insulation of the air outlet. Apply the accessory

sealing material under the field supply insulation. Create an

overlap of 50 mm. If the entire outlet duct is thermally

insulated from the unit to the outside wall, the accessory

sealing material is not necessary.

a

d e

d e

f

g

c

g

b

≥

1000

50

250

(mm)

≥

1000

a

SV unit

b

Duct connection (air outlet)

c

Option kit EKBSDCK (air inlet)

d

Duct (field supply)

e

Insulation (field supply)

f

Sealing material (accessory)

g

Screw (field supply)

4

Protect the ducting against reverse airflow from wind.

5

Prevent that animals, debris and dust can enter the ducting.

6

If necessary, separate the duct and wall electrically.

7

Optionally: provide service holes in the ducting to make

maintenance easier.

8

Optionally: provide sound insulation. As the ducting is only used

when a refrigerant leak has been detected, it is not necessary

to insulate the ducting against noise. However, when the SV

unit is installed in sound-sensitive areas where additional

measures are taken, it can be advised to also insulate the

ducting.

13.5.2

To install the duct closing plate

The duct closing plate is only allowed if it is not necessary to

ventilate the enclosure for the SV unit. This means:

▪ when no safety measures are required, or

▪ when natural ventilation safety measure is required, or

▪ when an external alarm is required.

See

"12.3 To determine the required safety measures"

1

Remove the duct connection. Do not not throw away the

screws.

4×

PH2

SW8

2

Install the duct closing plate (accessory) using the same 4

screws.

Summary of Contents for VRV 5

Page 47: ......