17 Commissioning

Installation and operation manual

42

SV1ASV4~8A14AJV1B

VRV 5 safety valve unit

4P709466-1 – 2023.09

▪

No safety measure:

all SV units with no safety measures.

▪

External alarm:

all SV units with an external alarm.

▪

Natural ventilation:

all SV units with natural ventilation

▪

Ventilated enclosure

–

one SV

unit to one extraction fan

configuration:

all SV units with a ventilated enclosure – one-to-

one configuration.

▪

Ventilated enclosure

–

multiple SV

units to one extraction fan,

parallel configuration:

all SV units with a ventilated enclosure –

parallel configuration.

▪

Ventilated enclosure

–

multiple SV

units to one extraction fan,

series configuration:

only one SV unit with a ventilated

enclosure – series configuration. Tip: choose the SV unit which is

most upstream, where the air inlet (damper) is free and you can

measure the airflow rate.

Example

In the example below: change the setting [2-3] to start the test run

for the following SV units: a, b, d, e, f, g and h.

l

k

k

a

b

c

d

e

g

f

j

h

k

i

a

SV unit in one-to-one configuration

b

SV unit in series configuration

c

SV unit in series configuration

d

SV unit in parallel configuration

e

SV unit in parallel configuration

f

SV unit without safety measures

g

SV unit with external alarm

h

SV unit with natural ventilation

i

Natural ventilation

j

External alarm

k

Extraction fan

l

Outdoor unit

Interconnection wiring

In case the safety measures demand a ventilated enclosure, the SV

unit test run has to include a measurement of the actual extraction

airflow rate to confirm that it meets the legal requirements.

NOTICE

It is very important that all refrigerant piping work is done

before the units (outdoor, SV or indoor) are powered.

When the units are powered, the expansion valves

initialise. This means that the valves close.

If any part of the system had already been powered before,

FIRST activate setting [2-21] on the outdoor unit to open

the expansion valves again THEN power off the unit to

conduct the SV unit test run.

17.2.2

About airflow requirements

When a ventilated enclosure is required, the following requirements

apply:

▪ pressure inside the SV unit has to be more than 20 Pa below the

ambient pressure,

▪ minimum airflow rate:

Model

Minimum airflow rate [m³/h]

SV1A

82

SV4A

82

SV6~8A

84

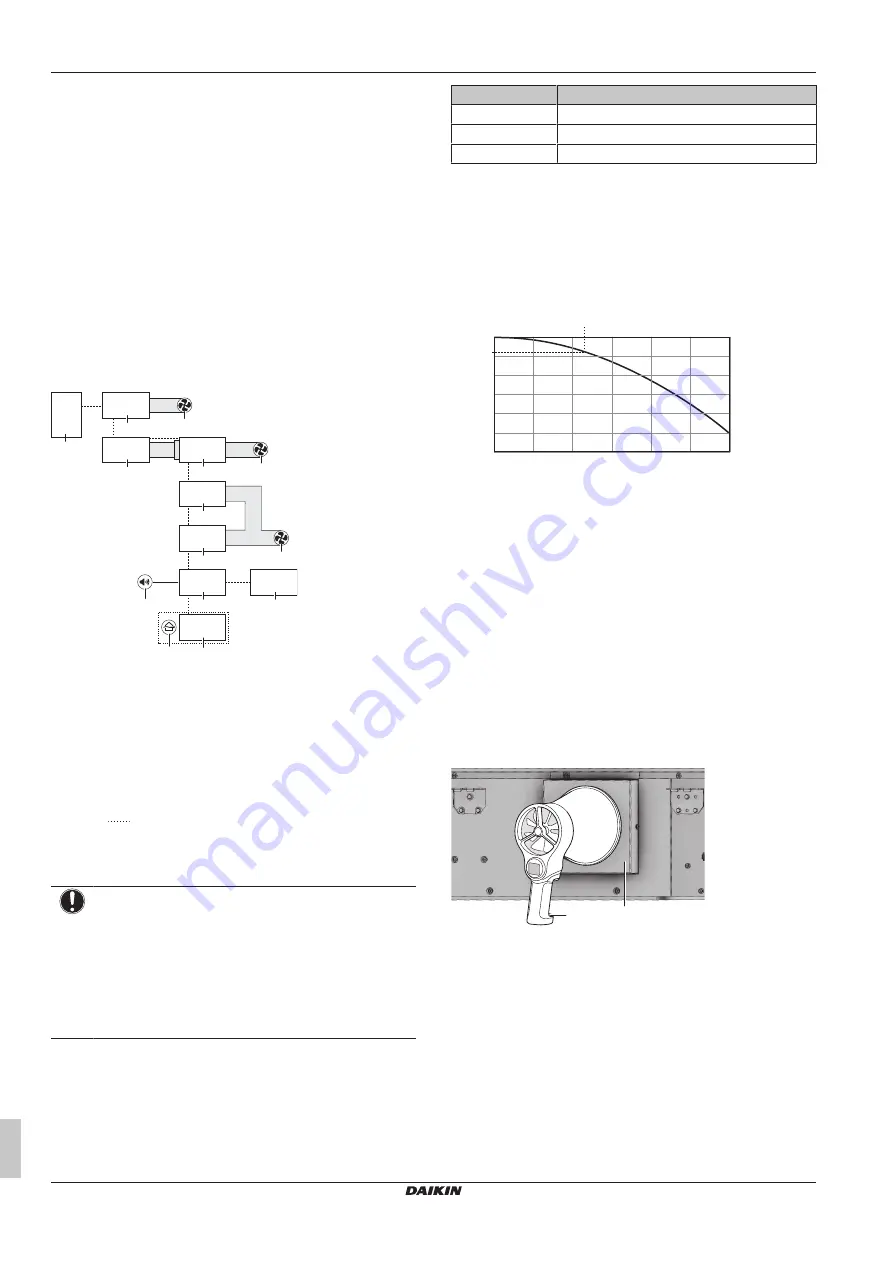

Example

A SV8A unit with an airflow rate during the test run of 115 m³/h. The

pressure drop graph shows that this results in an internal pressure

which is 38 Pa below the ambient pressure. Both requirements are

met:

▪ The pressure inside the SV unit is more than 20 Pa below the

ambient pressure (38 Pa).

▪ The airflow rate is higher than 84 m³/h (115 m³/h).

- 38.01

115

P

INTERNAL

[Pa]

-300

-250

-200

-150

-100

0

0

50

100

150

200

250

300

-50

AFR

OUT

[m³/h]

AFR

OUT

Airflow rate [m³/h]

P

internal

Internal pressure below ambient pressure [Pa]

See the latest version of the technical engineering data for the SV

unit's pressure drop curves.

17.2.3

About measuring the airflow rate

It is up to the installer to measure the airflow rate and provide correct

data. We advise two ways in the sections below, but the installer is

entirely free on how to perform the measurement.

About measuring with a vane anemometer

▪ Where: Measure the airflow rate at the air inlet (damper) of the SV

unit.

▪ Tip: Use the duct connection kit (EKBSDCK) and an anemometer

with a funnel to conduct the entire airflow through the

anemometer.

▪ Postrequisite: Remove the kit once the measurement is finished.

b

a

a

Vane anemometer

b

Duct connection kit (EKBSDCK)

About measuring with a hot wire probe anemometer

▪ Attention: In case you need to drill holes in the ducting, choose a

location without thermal insulation.

▪ Where: Measure the airflow rate in the duct connected to the air

outlet of the SV unit.

▪ Postrequisite: Close the holes properly once the measurement is

finished.

Summary of Contents for VRV 5

Page 47: ......