12 Special requirements for R32 units

Installation and operation manual

13

SV1ASV4~8A14AJV1B

VRV 5 safety valve unit

4P709466-1 – 2023.09

e

Remote controller in

normal mode

f

Remote controller in

alarm only mode

g

Remote controller in

supervisor mode

(mandatory in

some situations)

h

Centralised controller (optional)

i

Option PCB (optional)

j

Cool/heat changeover remote control switch (optional)

Refrigerant piping

Interconnection and user interface wiring

Direct connection of indoor units to the outdoor unit

11.4

Combining units and options

INFORMATION

Certain options may NOT be available in your country.

11.4.1

Possible options for the SV unit

INFORMATION

All possible options are mentioned in the option list below.

For more information about an option, see the installation

and operation manual of the option.

Duct connection kit (EKBSDCK)

This kit is required when you install ducting on the air inlet side. See

the examples in

"13.2 Possible configurations"

24] and

This kit can also be used when measuring the airflow. See

"17.2.3 About measuring the airflow rate"

Joint kit (EKBSJK)(only for SV4~8A)

This kit is required when you make a connection with e.g.

FXMA200A and FXMA250A. When using the joint kit, change the

DIP switch settings. See

"15.5 To set the DIP switches"

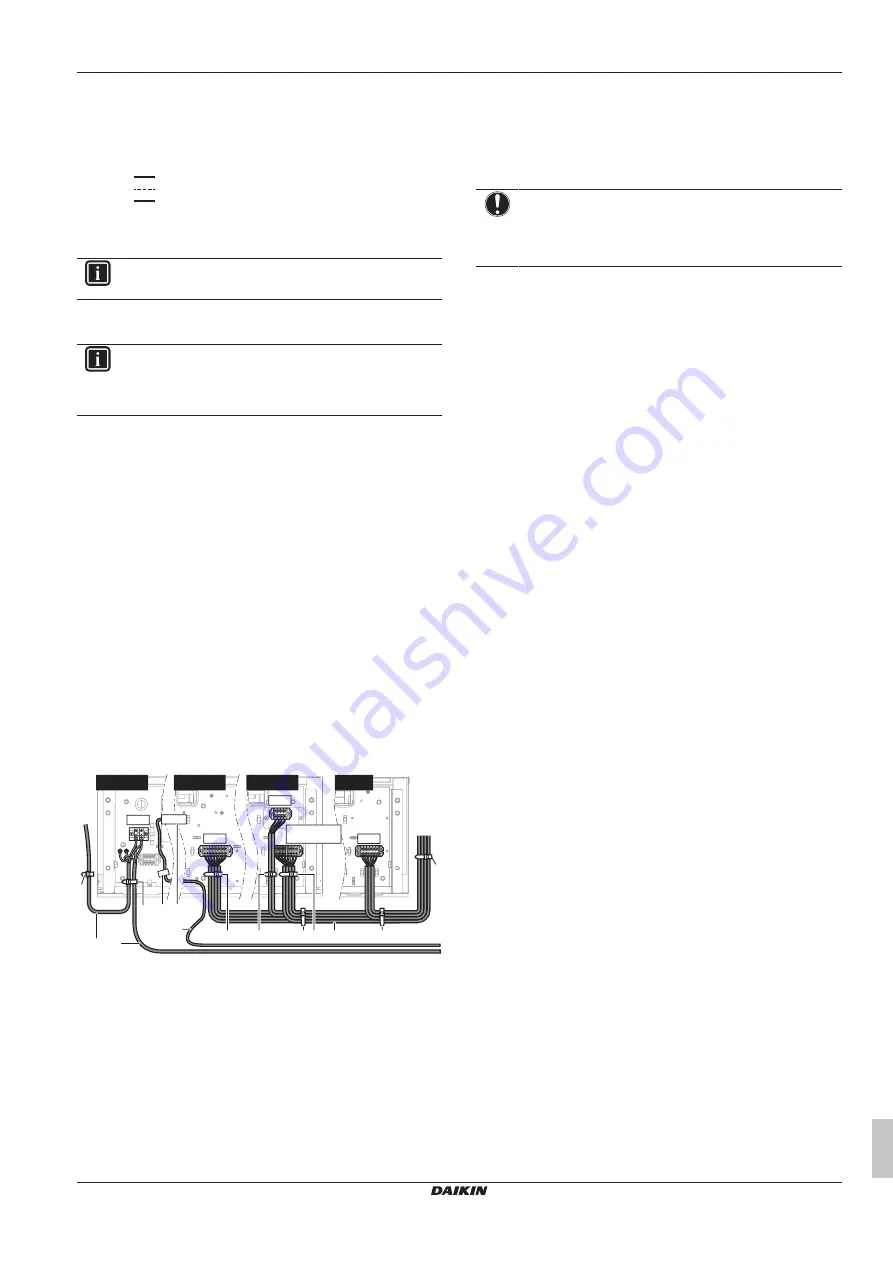

Drain up kit (K-KDU303KVE)

▪ Only this optional drain up kit can be used on the SV unit. Do NOT

use another drain pump kit.

▪ Do NOT route the interconnection wiring of the SV unit together

with the power supply wire of the drain up kit.

▪ Route the power supply wire and relay harness of the drain up kit

inside the SV unit as shown in the figure below.

▪ Position the ferrite core on the relay harness of the drain up kit

inside the switch box of the SV unit.

c

SV1~8A

X1M

X3M

X2M

SV6~8A

SV4~8A

c

SV1A

SV6~8=X4M

SV4A=X3M

X3M

e

X15A

f

g

c

c

c c b

c

d

c

a

a

Power supply for the SV unit

b

Interconnection wiring

c

Cable tie

d

Power supply of the drain up kit

e

Relay harness of the drain up kit

f

Relay connector of the drain up kit

g

Ferrite core

12

Special requirements for R32

units

12.1

Installation space requirements

NOTICE

▪ The pipework shall be securely mounted and guarded

protected from physical damage.

▪ Keep the pipework installation to a minimum.

12.2

System layout requirements

The VRV 5 heat pump uses R32 refrigerant, which is rated as A2L

and is mildly flammable.

To comply with the requirements of enhanced tightness refrigerating

systems of the IEC 60335-2-40, this system is equipped with shut-off

valves in the SV unit and an alarm in the remote controller.

The safety measures that are needed for the SV unit are explained

in more detail below. If they are followed, no additional safety

measures for the SV unit are required. Carefully follow the

installation requirements for the SV unit as explained in this manual.

Follow the installation requirements described in the outdoor unit

and indoor unit installation and operation manuals to ensure that the

complete system is compliant with legislation.

Outdoor unit installation

For installation of the outdoor unit, see the installation and operation

manual delivered with the outdoor unit.

Indoor unit installation

Room area limitations apply for the indoor units. Details are

explained in the installation and operation manual delivered with the

outdoor unit. For installation of the indoor unit, see the installation

and operation manual delivered with the indoor unit. For

compatibility of indoor units, see the latest version of the technical

data book of the outdoor unit.

Remote controller requirements

To install the remote controller, see the installation and operation

manual delivered with the remote controller. For requirements on

where and how to use a remote controller and which type to use,

see the installation and operation manual delivered with the outdoor

unit.

SV unit installation

Depending on the room size in which the SV unit is installed and the

total amount of refrigerant in the system, other safety measures are

necessary. See

"12.3 To determine the required safety

14]. For the total amount of refrigerant in the system,

see the installation and operation manual delivered with the outdoor

unit.

A terminal for external output is available in the SV unit. This SVS

output can be used when additional countermeasures are needed,

or when the SV unit is installed in a room size where an external

alarm is a sufficient safety measure. The SVS output is a potential-

free contact on terminal X6M that closes in case a refrigerant leak is

detected or if the R32 sensor of the SV unit fails or is disconnected.

For more information about the SVS output, see

36].

Summary of Contents for VRV 5

Page 47: ......