12 Special requirements for R32 units

Installation and operation manual

16

SV1ASV4~8A14AJV1B

VRV 5 safety valve unit

4P709466-1 – 2023.09

12.4

Safety measures

12.4.1

No safety measure

When the room area is sufficiently large, no safety measures are

required. This also includes a SV unit installed in the lowest

underground floor.

The duct connection must be replaced with the duct closing plate

accessory (see

"13.5.2 To install the duct closing plate"

Field settings

No safety measure

Code

Description

Value

[2-0]

(a)

Cluster indication

0 (default): disable

[2-4]

(b)

Safety measures

0: disable

(a)

Set on ALL main PCBs (A1P and A2P) of the SV unit.

(b)

Set ONLY on the LEFTMOST main PCB (A1P) of the SV unit.

Note:

For more information, see

SV unit test run

Before SV unit operation, it is required to perform a test run that

simulates a refrigerant leak. See

41] for

more details.

12.4.2

External alarm

Do NOT use the external alarm safety measure in case the SV unit

is installed in an occupied space where people are restricted in their

movement.

For the external alarm safety measure, the duct connection must be

replaced with the duct closing plate accessory (see

27]).

An external alarm circuit (field supply) must be connected to the SVS

output of the SV unit, see

This alarm system must warn audibly AND visibly (e.g. a loud buzzer

AND a flashing light). The audible alarm must be 15 dBA above the

background sound level at all times.

At least one alarm must be installed in the occupied space in which

the SV unit is installed.

For the occupancy listed below, the alarm system must

additionally

warn at a supervised location with 24-hour monitoring:

▪ with sleeping facilities.

▪ where an uncontrolled number of people are present.

▪ accessible for persons not familiar with the necessary safety

precautions.

To warn at a supervised location, connect a supervisor remote

controller to the system. This supervisor remote controller can be

connected to any indoor unit of the system, and will warn at the

supervised location in case a refrigerant leak is detected in any SV

unit of the system.

Note:

An address number for the supervisor

remote controller must be assigned to the SV unit. See

37].

When the R32 sensor in the SV unit detects a refrigerant leak, the

SVS output will close and activate the alarm. An error message will

display on the remote controllers of the connected indoor units. See

44].

Field settings

External alarm

Code

Description

Value

[2-0]

(a)

Cluster indication

0 (default): disable

[2-4]

(b)

Safety measures

1 (default): enable

[2-7]

(b)

Ventilated enclosure

0: disable

(a)

Set on ALL main PCBs (A1P and A2P) of the SV unit.

(b)

Set ONLY on the LEFTMOST main PCB (A1P) of the SV unit.

Note:

SV unit test run

Before SV unit operation, it is required to perform a test run that

simulates a refrigerant leak. See

41] for

more details.

12.4.3

Natural ventilation

Natural ventilation is a safety measure where ventilation is made to a

place where sufficient air is available to dilute the leaked refrigerant

such as a large space.

The duct connection must be replaced with the duct closing plate

accessory (see

"13.5.2 To install the duct closing plate"

27]).

The natural ventilation safety measure can be applied by following

the steps below:

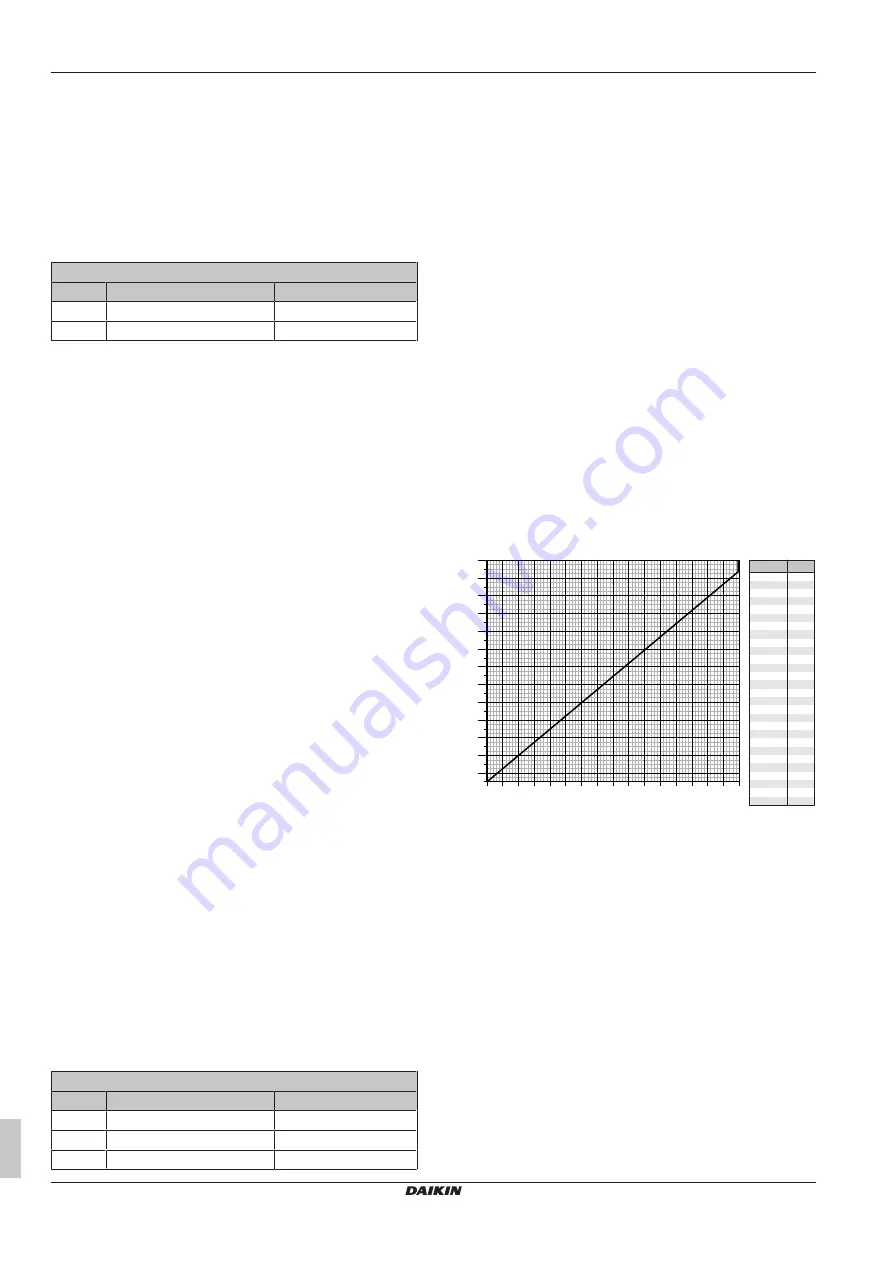

Step 1

– Determine total room area, which is the total area of the

space that has natural ventilation

and

the space in which the SV unit

is installed:

The respective room area can be determined by projecting the walls,

doors and partitions to the floor and calculating the enclosed area.

Spaces connected only through false ceilings, ductwork, or similar

connections are not considered a single space.

Step 2

– Use the graph or table below to determine the total

refrigerant charge limit in the system:

Note:

Round down the derived values.

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

5

0

25 30 35 40 45 50 55 60 65

20

15

10

70 75 80

m

[kg]

A

1

+ A

min

[m

2

]

A

1

+ A

min

[m²]

m

[kg]

20

6.7

30

10.1

40

0

0

10

3.3

13.5

50

16.8

60

20.2

70

23.6

80

27.0

90

30.3

100

33.7

110

37.1

120

40.5

130

43.9

140

47.2

150

50.6

160

54.0

170

57.4

180

60.7

190

64.1

200

67.5

210

70.9

220

74.2

230

77.6

236

79.6

237

79.8

240

79.8

250

79.8

m

Total refrigerant charge in the system [kg]

A

1

Area of the room with natural ventilation [m²]

A

min

Minimum room area of the space in which the SV unit is

installed [m²]

The graphs and table are based on an installation height of the SV

unit between 1.8 m and 2.2 m. The installation height is the height of

the bottom of the SV unit to the floor. See also

site requirements of the unit"

23].

If the installation height is more than 2.2 m, higher total refrigerant

charge limit of the system can apply. To know the total refrigerant

charge limit of the system in case the installation height is more than

2.2 m, refer to the online tool (

).

Step 3

– The total amount of refrigerant in the system MUST be less

than the refrigerant charge limit derived from the graph above. If

NOT, natural ventilation safety measure is not allowed.

Step 4

– The partition between two rooms on the same floor MUST

meet one of the following two requirements for natural ventilation.

▪ Rooms on the same floor that are connected with a permanent

opening that extends to the floor and is intended for people to

walk through.

Summary of Contents for VRV 5

Page 47: ......