13 Unit installation

Installation and operation manual

23

SV1ASV4~8A14AJV1B

VRV 5 safety valve unit

4P709466-1 – 2023.09

13

Unit installation

WARNING

The installation MUST comply with the requirements that

apply to this R32 equipment. For more information, see

"12 Special requirements for R32 units"

13.1

Preparing the installation site

Avoid installation in an environment with a lot of organic solvents

such as ink and siloxane.

Do NOT install the unit in places often used as work place. In case

of construction works (e.g. grinding works) where a lot of dust is

created, the unit MUST be covered.

Choose an installation location with sufficient space to carry the unit

in and out of the site.

WARNING

The appliance shall be stored as follows:

▪ in such a way as to prevent mechanical damage.

▪ in a well-ventilated room without continuously operating

ignition sources (example: open flames, an operating

gas appliance or an operating electric heater).

▪ in a room with dimensions as specified in

13].

13.1.1

Installation site requirements of the unit

CAUTION

Appliance NOT accessible to the general public. Install it in

a secured area, protected from easy access.

This unit is suitable for installation in a commercial,

industrial, household and residential environment.

INFORMATION

The sound pressure level is less than 70 dBA.

INFORMATION

Also read the following requirements:

▪ Service space requirements. See below in this topic.

▪ Refrigerant piping requirements. See

30].

Safety measures differ depending on the total amount of refrigerant

in the system and on the floor area. See

14].

The SV unit is designed for indoor installation only. Always respect

the following conditions.

Ambient condition

Value

Indoor temperature

5~32°C DB

Indoor humidity

≤80%

Do NOT install the unit in the following places:

▪ In places where a mineral oil mist, spray or vapour may be

present in the atmosphere. Plastic parts may deteriorate and fall

off or cause water leakage.

▪ Where acidic or alkaline vapour is present.

▪ In vehicles or vessels.

It is NOT recommended to install the unit in the following places

because it may shorten the life of the unit:

▪ In places where voltage fluctuates a lot.

▪

Water leakage.

Take care that in the event of a water leak, water

CANNOT cause any damage to the installation space and its

surroundings.

▪

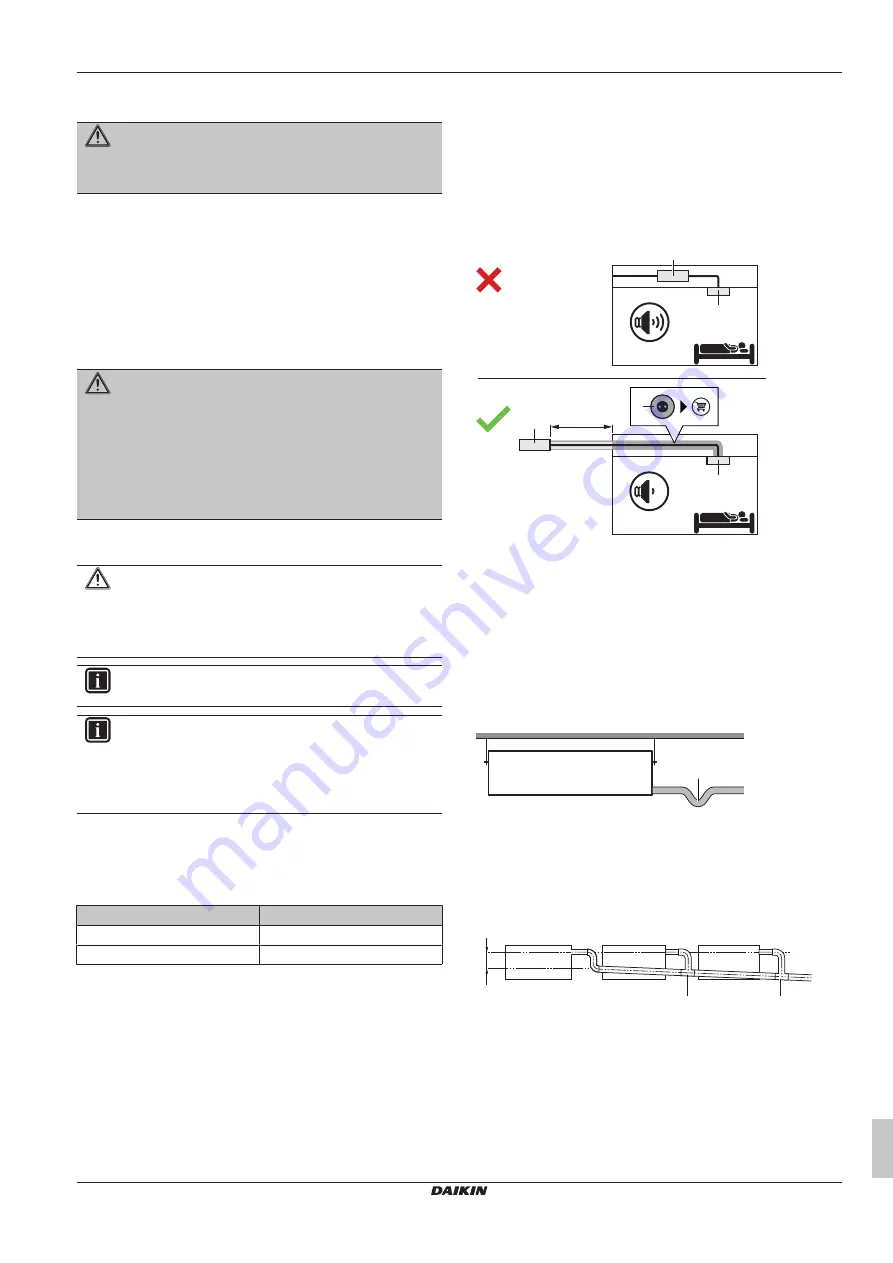

Noise.

Choose a location where the operation noise of the unit

does not disturb the room occupants. To avoid that the refrigerant

noise disturbs the people in the room, keep at least 5 m of piping

between the occupied room and the SV unit. If there is no false

ceiling in the room, it is advised to add sound insulation around

the piping between the SV unit and the indoor unit, or to keep

more length between the SV unit and the indoor unit.

>5 m

c

a

b

b

a

a

SV unit

b

Indoor unit

c

Sound insulation (field supply)

▪

Drainage.

Make sure condensation water can be evacuated

properly.

▪

Drain pipe length.

Keep drain piping as short as possible.

▪

Drain pipe size.

Keep the pipe size equal to or greater than that

of the connecting pipe (vinyl pipe of 20 mm nominal diameter and

26 mm outer diameter).

▪

Bad odours.

To prevent bad odours and air going into the unit

through the drain piping, install a trap.

a

a

Trap

▪

Ammonia.

Do not connect the drain piping directly to sewage

pipes that smell of ammonia. The ammonia in the sewage pipe

might enter the unit through the drain piping and cause corrosion.

▪

Combining drain pipes.

It is possible to combine drain pipes.

Use drain pipes and T-joints with the correct gauge for the

operating capacity of the units.

≥100

a

a

a

T-joint

▪

Spacing.

Respect the following requirements:

Summary of Contents for VRV 5

Page 47: ......