2 Specific installer safety instructions

Installation and operation manual

6

SV1ASV4~8A14AJV1B

VRV 5 safety valve unit

4P709466-1 – 2023.09

CAUTION

Do NOT insert fingers, rods or other objects into the air

inlet (damper).

WARNING

Safety shut-off valves shall only be replaced with valves

specified by the appliance manufacturer.

DANGER: RISK OF ELECTROCUTION

DANGER: RISK OF ELECTROCUTION

Do NOT leave the unit unattended when the service cover

is removed.

DANGER: RISK OF BURNING/SCALDING

WARNING

Prevent hazards due to inadvertent resetting of the thermal

cut-out: power to this appliance MUST NOT be supplied

through an external switching device, such as a timer, or

connected to a circuit that is regularly turned ON and OFF

by the utility.

WARNING

▪ When carrying out an inspection on the switch box of

the unit, ALWAYS make sure that the unit is

disconnected from the mains. Turn off the respective

circuit breaker.

▪ When a safety device was activated, stop the unit and

find out why the safety device was activated before

resetting it. NEVER shunt safety devices or change

their values to a value other than the factory default

setting. If you are unable to find the cause of the

problem, call your dealer.

2.1

Instructions for equipment using

R32 refrigerant

WARNING: MILDLY FLAMMABLE MATERIAL

The refrigerant inside this unit is mildly flammable.

WARNING

▪ Do NOT pierce or burn refrigerant cycle parts.

▪ Do NOT use cleaning materials or means to accelerate

the defrosting process other than those recommended

by the manufacturer.

▪ Be aware that the refrigerant inside the system is

odourless.

WARNING

The appliance shall be stored as follows:

▪ in such a way as to prevent mechanical damage.

▪ in a well-ventilated room without continuously operating

ignition sources (example: open flames, an operating

gas appliance or an operating electric heater).

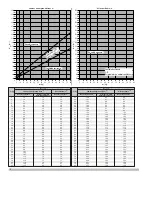

▪ in a room with dimensions as specified in

WARNING

Make sure installation, servicing, maintenance and repair

comply with instructions from Daikin and with applicable

legislation (for example national gas regulation) and are

executed ONLY by authorised persons.

WARNING

Refrigerant sensors of the refrigerant detection system

shall only be replaced with refrigerant sensors specified by

the appliance manufacturer.

WARNING

Safety shut-off valves shall not be reset until the room has

been ventilated. Resetting may result in additional

flammable refrigerant to be released into the room.

WARNING

▪ Take precautions to avoid excessive vibration or

pulsation to refrigeration piping.

▪ Protect the protection devices, piping and fittings as

much as possible against adverse environmental

effects.

▪ Provide space for expansion and contraction of long

runs of piping.

▪ Design and install piping in refrigerating systems such

as to minimise the likelihood of hydraulic shock

damaging the system.

▪ Mount the indoor equipment and pipes securely and

protect them to avoid accidental rupture of equipment

or pipes in case of events such as moving furniture or

reconstruction activities.

CAUTION

Do NOT use potential sources of ignition in searching for

or detection of refrigerant leaks.

NOTICE

▪ Do NOT re-use joints and copper gaskets which have

been used already.

▪ Joints made in the installation between parts of the

refrigerant system shall be accessible for maintenance

purposes.

See

"12.3 To determine the required safety measures"

14] to

check if your system meets the R32 safety requirements.

Summary of Contents for VRV 5

Page 47: ......