Field Setting

Si39-504

124

Test Operation

3.2

Field Setting from Outdoor Unit

3.2.1

Field Setting from Outdoor Unit

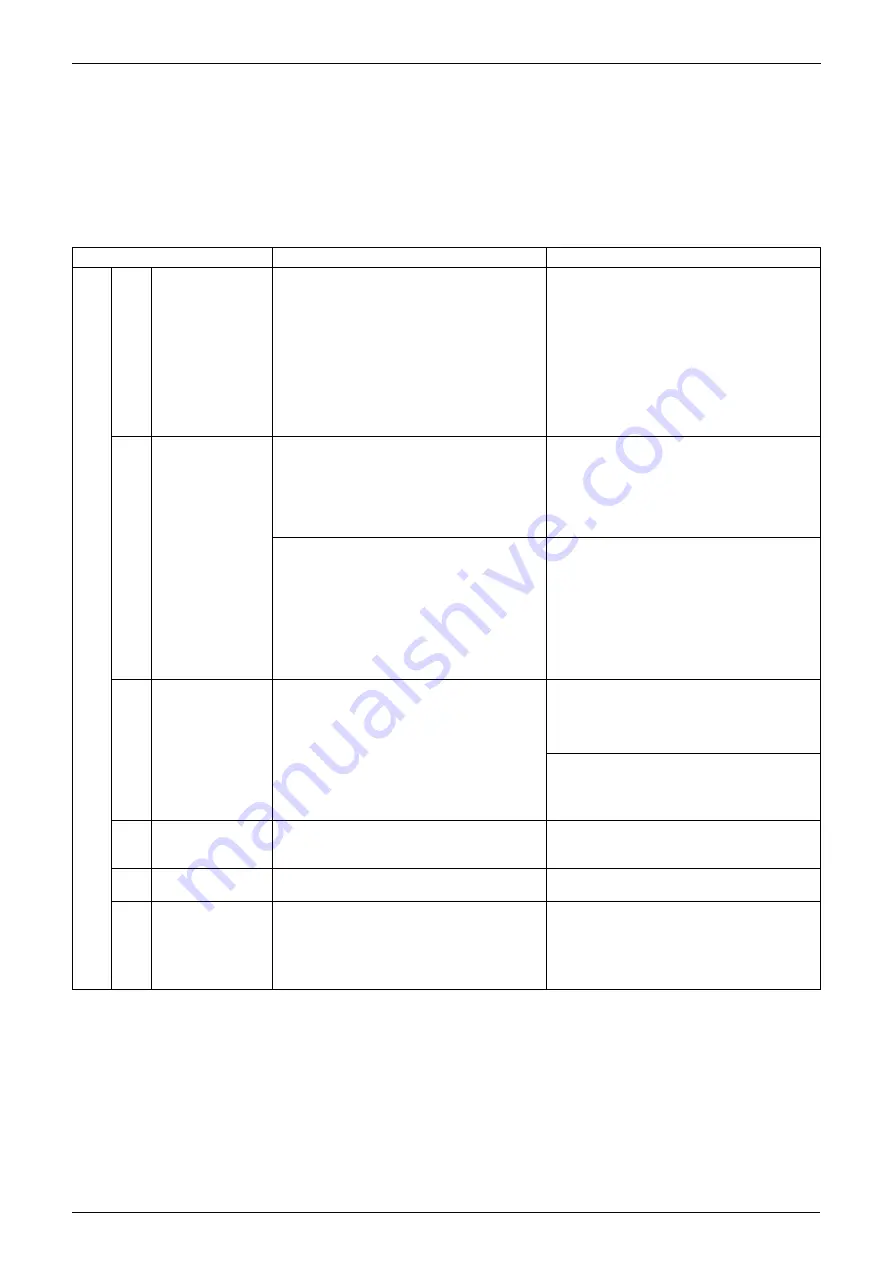

List of Field Setting Items

This following section indicates the list of field setting items. For the lists of dip switch contents,

Setting mode 1, and Setting mode 2, refer to information in tables shown on the following page

onward.

For setting items of (*1), refer to detailed information provided on page 136 onward.

Setting item

Content and objective of setting

Overview of setting procedure

Fun

c

ti

on se

ttin

g

1

Setting of COOL/

HEAT selection

(*1)

COOL/HEAT selection methods are

selectable from the following

(1) Control by each outdoor unit using the

indoor unit remote controller

(2) Control by each outdoor unit using the

COOL/HEAT selection remote

controller

(3) Batch control by outdoor unit group

using the indoor unit remote controller

(4) Batch control by outdoor unit group

using the COOL/HEAT selection

remote controller

In order to use the COOL/HEAT selection

remote controller, set the DS1-1 on the

outdoor unit PC board to OUT.

For outdoor unit group control, set the

system to "BATCH MASTER" or "SLAVE"

while in "Setting mode 1". Then, make

setting of COOL/HEAT batch address.

2

Setting of low noise

operation (*1)

A. Use external input to step down the upper

limit of the fan (factory set to Step 8),

providing low noise level.

(1) Mode 1: Step 6 or lower

(2) Mode 2: Step 5 or lower

(3) Mode 3: Step 4 or lower

Use the "External control adaptor for

outdoor unit".

Set to "External control adaptor for outdoor

unit" with No. 12 of "Setting mode 2" and

select the mode with No. 25.

If necessary, set the "Capacity priority

setting" to ON with No. 29.

B. The low noise operation aforementioned is

enabled in nighttime automatic low noise

operation mode.

Start time: Selectable in the range of 20:00

to 24:00 hours.

End time: Selectable in the range of 06:00

to 08:00 hours.

(Use the said time as a guide since the

start time and the end time are estimated

according to outdoor temperatures.)

Make this setting while in "Setting mode 2".

Select a mode with No. 22 of "Setting mode

2".

Select the start time with No. 26 and the

end time with No. 27.

If necessary, set the "Capacity priority

setting" to ON with No. 29.

3

Setting of demand

operation (*1)

Used to place limits on the compressor

operating frequency to control the upper

limit of power consumption.

(1) Mode 1 of Demand 1: 60% or less of

rating

(2) Mode 2 of Demand 1: 70% or less of

rating

(3) Mode 3 of Demand 1: 80% or less of

rating

(4) Demand 2: 40% or less of rating

For setting with the use of "external control

adapter":

Set the system to "External control adaptor

for outdoor unit" with No. 12 of Setting

mode 2" and select the mode with No. 30.

For setting only in "Setting mode 2":

Set the system to Normal demand mode

with No. 32 of "Setting mode 2" and select

the mode with No. 30.

4

Setting of AirNet

address

Used to make address setting with AirNet

connected.

Set the AirNet to an intended address

using binary numbers with No. 13 of

"Setting mode 2".

5

Setting of hot water

heater

Make this setting to conduct heating

operation using the hot water heater.

Set No. 16 of "Setting mode 2" to ON.

6

Setting of high

static pressure

Make this setting to operate a system with

diffuser duct while in high static pressure

mode. (Use this setting mode when shields

are installed on upper floors or balconies.)

* In order to mount the diffuser duct, remove

the cover from the outdoor unit fan.

Set No. 18 of "Setting mode 2" to ON.

Summary of Contents for VRV II RXYQ5MATL

Page 53: ...Specifications Si39 504 42 Specifications...

Page 115: ...Outline of Control Indoor Unit Si39 504 104 Function...

Page 161: ...Field Setting Si39 504 150 Test Operation...

Page 172: ...Si39 504 Troubleshooting by Remote Controller Troubleshooting 161...

Page 266: ...Si39 504 Piping Diagrams Appendix 255 RXYQ8MA 10MA 12MAYL E TL E 3D048033A...

Page 267: ...Piping Diagrams Si39 504 256 Appendix RXYQ14MA 16MAYL E TL E 3D048034A...

Page 271: ...Wiring Diagrams for Reference Si39 504 260 Appendix RXYQ8MA 10MA 12MAYL E 3D047088C...

Page 272: ...Si39 504 Wiring Diagrams for Reference Appendix 261 RXYQ14MA 16MAYL E 3D047089C...

Page 273: ...Wiring Diagrams for Reference Si39 504 262 Appendix 2 1 2 RXYQ MATL E RXYQ5MATL E 3D049059A...

Page 274: ...Si39 504 Wiring Diagrams for Reference Appendix 263 RXYQ8MA 10MA 12MATL E 3D049060A...

Page 275: ...Wiring Diagrams for Reference Si39 504 264 Appendix RXYQ14MA 16MATL E 3D049061A...

Page 283: ...Wiring Diagrams for Reference Si39 504 272 Appendix FXCQ40M 50M 80M 125MVE 3D039557A...

Page 285: ...Wiring Diagrams for Reference Si39 504 274 Appendix FXKQ25M 32M 40M 63MVE 3D039564B...

Page 289: ...Wiring Diagrams for Reference Si39 504 278 Appendix FXMQ40M 50M 63M 80M 100M 125MVE 3D039620B...

Page 290: ...Si39 504 Wiring Diagrams for Reference Appendix 279 FXMQ200M 250MVE 3D039621B...

Page 291: ...Wiring Diagrams for Reference Si39 504 280 Appendix FXHQ32M 63M 100MVE 3D039801D...

Page 292: ...Si39 504 Wiring Diagrams for Reference Appendix 281 FXAQ20M 25M 32MVE 40M 50M 63MVE 3D034206C...

Page 309: ...Selection of Pipe Size Joints and Header Si39 504 298 Appendix Note 1...

Page 315: ...Method of Replacing The Inverter s Power Transistors and Diode Modules Si39 504 304 Appendix...