Si37-701

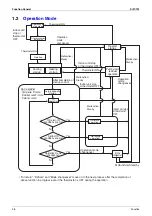

Basic Control

Function

107

(To decrease Step No.)

STEP

No.

unit 1

INV

unit 2

INV

unit 3

INV

STD

1

52Hz

2

56Hz

3

62Hz

4

68Hz

5

74Hz

6

80Hz

7

88Hz

8

96Hz

9

104Hz

10

52Hz

52Hz

11

56Hz

56Hz

12

62Hz

62Hz

13

66Hz

66Hz

14

70Hz

70Hz

15

74Hz

74Hz

16

52Hz

52Hz

52Hz

17

56Hz

56Hz

56Hz

18

62Hz

62Hz

62Hz

19

66Hz

66Hz

66Hz

20

68Hz

68Hz

68Hz

21

70Hz

70Hz

70Hz

22

74Hz

74Hz

74Hz

23

80Hz

80Hz

80Hz

24

88Hz

88Hz

88Hz

25

96Hz

96Hz

96Hz

26

52Hz

52Hz

52Hz

ON1

27

62Hz

62Hz

62Hz

ON1

28

68Hz

68Hz

68Hz

ON1

29

74Hz

74Hz

74Hz

ON1

30

80Hz

80Hz

80Hz

ON1

31

88Hz

88Hz

88Hz

ON1

32

96Hz

96Hz

96Hz

ON1

33

104Hz

104Hz

104Hz

ON1

34

52Hz

52Hz

52Hz

ON2

35

62Hz

62Hz

62Hz

ON2

36

74Hz

74Hz

74Hz

ON2

37

88Hz

88Hz

88Hz

ON2

38

96Hz

96Hz

96Hz

ON2

39

52Hz

52Hz

52Hz

ON3

40

62Hz

62Hz

62Hz

ON3

41

74Hz

74Hz

74Hz

ON3

42

92Hz

92Hz

92Hz

ON3

43

104Hz

104Hz

104Hz

ON3

44

52Hz

52Hz

52Hz

ON4

45

62Hz

62Hz

62Hz

ON4

46

74Hz

74Hz

74Hz

ON4

47

96Hz

96Hz

96Hz

ON4

48

52Hz

52Hz

52Hz

ON5

49

68Hz

68Hz

68Hz

ON5

50

80Hz

80Hz

80Hz

ON5

51

96Hz

96Hz

96Hz

ON5

52

104Hz

104Hz

104Hz

ON5

53

116Hz

116Hz

116Hz

ON5

54

124Hz

124Hz

124Hz

ON5

55

144Hz

144Hz

144Hz

ON5

56

158Hz

158Hz

158Hz

ON5

57

166Hz

166Hz

166Hz

ON5

58

176Hz

176Hz

176Hz

ON5

59

188Hz

188Hz

188Hz

ON5

60

202Hz

202Hz

202Hz

ON5

61

210Hz

210Hz

210Hz

ON5

(To decrease Step No.)

STEP

No.

unit 1

INV

unit 2

INV

unit 3

INV

STD

1

52Hz

2

56Hz

3

62Hz

4

68Hz

5

74Hz

6

80Hz

7

88Hz

8

96Hz

9

104Hz

10

52Hz

52Hz

11

56Hz

56Hz

12

62Hz

62Hz

13

66Hz

66Hz

14

70Hz

70Hz

15

74Hz

74Hz

16

52Hz

52Hz

52Hz

17

56Hz

56Hz

56Hz

18

62Hz

62Hz

62Hz

19

66Hz

66Hz

66Hz

20

68Hz

68Hz

68Hz

21

70Hz

70Hz

70Hz

22

74Hz

74Hz

74Hz

23

80Hz

80Hz

80Hz

24

88Hz

88Hz

88Hz

25

96Hz

96Hz

96Hz

26

52Hz

52Hz

52Hz

ON1

27

62Hz

62Hz

62Hz

ON1

28

68Hz

68Hz

68Hz

ON1

29

74Hz

74Hz

74Hz

ON1

30

80Hz

80Hz

80Hz

ON1

31

88Hz

88Hz

88Hz

ON1

32

96Hz

96Hz

96Hz

ON1

33

104Hz

104Hz

104Hz

ON1

34

52Hz

52Hz

52Hz

ON2

35

62Hz

62Hz

62Hz

ON2

36

74Hz

74Hz

74Hz

ON2

37

88Hz

88Hz

88Hz

ON2

38

96Hz

96Hz

96Hz

ON2

39

52Hz

52Hz

52Hz

ON3

40

62Hz

62Hz

62Hz

ON3

41

74Hz

74Hz

74Hz

ON3

42

92Hz

92Hz

92Hz

ON3

43

104Hz

104Hz

104Hz

ON3

44

52Hz

52Hz

52Hz

ON4

45

62Hz

62Hz

62Hz

ON4

46

74Hz

74Hz

74Hz

ON4

47

96Hz

96Hz

96Hz

ON4

48

104Hz

104Hz

104Hz

ON4

49

52Hz

52Hz

52Hz

ON5

50

68Hz

68Hz

68Hz

ON5

51

80Hz

80Hz

80Hz

ON5

52

96Hz

96Hz

96Hz

ON5

53

104Hz

104Hz

104Hz

ON5

54

52Hz

52Hz

52Hz

ON6

55

68Hz

68Hz

68Hz

ON6

56

80Hz

80Hz

80Hz

ON6

57

96Hz

96Hz

96Hz

ON6

58

104Hz

104Hz

104Hz

ON6

59

116Hz

116Hz

116Hz

ON6

60

124Hz

124Hz

124Hz

ON6

61

144Hz

144Hz

144Hz

ON6

62

158Hz

158Hz

158Hz

ON6

63

166Hz

166Hz

166Hz

ON6

64

176Hz

176Hz

176Hz

ON6

65

188Hz

188Hz

188Hz

ON6

66

202Hz

202Hz

202Hz

ON6

67

210Hz

210Hz

210Hz

ON6

REYQ42PY1, 44PY1 (10/12+16+16HP)

(To increase Step No.)

STEP

No.

unit 1

INV

unit 2

INV

unit 3

INV

STD

1

52Hz

52Hz

52Hz

2

56Hz

56Hz

56Hz

3

62Hz

62Hz

62Hz

4

66Hz

66Hz

66Hz

5

68Hz

68Hz

68Hz

6

70Hz

70Hz

70Hz

7

74Hz

74Hz

74Hz

8

80Hz

80Hz

80Hz

9

88Hz

88Hz

88Hz

10

96Hz

96Hz

96Hz

11

104Hz

104Hz

104Hz

12

110Hz

110Hz

110Hz

13

116Hz

116Hz

116Hz

14

124Hz

124Hz

124Hz

15

80Hz

80Hz

80Hz

ON1

16

88Hz

88Hz

88Hz

ON1

17

96Hz

96Hz

96Hz

ON1

18

104Hz

104Hz

104Hz

ON1

19

116Hz

116Hz

116Hz

ON1

20

124Hz

124Hz

124Hz

ON1

21

132Hz

132Hz

132Hz

ON1

22

88Hz

88Hz

88Hz

ON2

23

96Hz

96Hz

96Hz

ON2

24

104Hz

104Hz

104Hz

ON2

25

124Hz

124Hz

124Hz

ON2

26

144Hz

144Hz

144Hz

ON2

27

92Hz

92Hz

92Hz

ON3

28

104Hz

104Hz

104Hz

ON3

29

116Hz

116Hz

116Hz

ON3

30

124Hz

124Hz

124Hz

ON3

31

144Hz

144Hz

144Hz

ON3

32

96Hz

96Hz

96Hz

ON4

33

104Hz

104Hz

104Hz

ON4

34

116Hz

116Hz

116Hz

ON4

35

124Hz

124Hz

124Hz

ON4

36

144Hz

144Hz

144Hz

ON4

37

96Hz

96Hz

96Hz

ON5

38

104Hz

104Hz

104Hz

ON5

39

116Hz

116Hz

116Hz

ON5

40

124Hz

124Hz

124Hz

ON5

41

144Hz

144Hz

144Hz

ON5

42

158Hz

158Hz

158Hz

ON5

43

166Hz

166Hz

166Hz

ON5

44

176Hz

176Hz

176Hz

ON5

45

188Hz

188Hz

188Hz

ON5

46

202Hz

202Hz

202Hz

ON5

47

210Hz

210Hz

210Hz

ON5

Initial step

Notes:

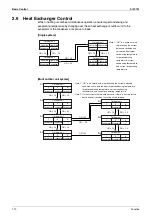

1. INV : Inverter compressor

STD : Standard compressor

Figures after ON represent the number of STD compressors in operation.

2. “Master unit”, and “slave unit” in this section are the names for control, and they will be transferred according to the

priority of rotation system.

3. Depending on the operating conditions of compressors, the compressors may run in patterns other than those

aforementioned.

REYQ46PY1, 48PY1 (14/16+16+16HP)

(To increase Step No.)

STEP

No.

unit 1

INV

unit 2

INV

unit 3

INV

STD

1

52Hz

52Hz

52Hz

2

56Hz

56Hz

56Hz

3

62Hz

62Hz

62Hz

4

66Hz

66Hz

66Hz

5

68Hz

68Hz

68Hz

6

70Hz

70Hz

70Hz

7

74Hz

74Hz

74Hz

8

80Hz

80Hz

80Hz

9

88Hz

88Hz

88Hz

10

96Hz

96Hz

96Hz

11

104Hz

104Hz

104Hz

12

110Hz

110Hz

110Hz

13

116Hz

116Hz

116Hz

14

124Hz

124Hz

124Hz

15

80Hz

80Hz

80Hz

ON1

16

88Hz

88Hz

88Hz

ON1

17

96Hz

96Hz

96Hz

ON1

18

104Hz

104Hz

104Hz

ON1

19

116Hz

116Hz

116Hz

ON1

20

124Hz

124Hz

124Hz

ON1

21

132Hz

132Hz

132Hz

ON1

22

88Hz

88Hz

88Hz

ON2

23

96Hz

96Hz

96Hz

ON2

24

104Hz

104Hz

104Hz

ON2

25

124Hz

124Hz

124Hz

ON2

26

144Hz

144Hz

144Hz

ON2

27

92Hz

92Hz

92Hz

ON3

28

104Hz

104Hz

104Hz

ON3

29

116Hz

116Hz

116Hz

ON3

30

124Hz

124Hz

124Hz

ON3

31

144Hz

144Hz

144Hz

ON3

32

96Hz

96Hz

96Hz

ON4

33

104Hz

104Hz

104Hz

ON4

34

116Hz

116Hz

116Hz

ON4

35

124Hz

124Hz

124Hz

ON4

36

144Hz

144Hz

144Hz

ON4

37

96Hz

96Hz

96Hz

ON5

38

104Hz

104Hz

104Hz

ON5

39

116Hz

116Hz

116Hz

ON5

40

124Hz

124Hz

124Hz

ON5

41

144Hz

144Hz

144Hz

ON5

42

96Hz

96Hz

96Hz

ON6

43

104Hz

104Hz

104Hz

ON6

44

116Hz

116Hz

116Hz

ON6

45

124Hz

124Hz

124Hz

ON6

46

144Hz

144Hz

144Hz

ON6

47

158Hz

158Hz

158Hz

ON6

48

166Hz

166Hz

166Hz

ON6

49

176Hz

176Hz

176Hz

ON6

50

188Hz

188Hz

188Hz

ON6

51

202Hz

202Hz

202Hz

ON6

52

210Hz

210Hz

210Hz

ON6

Initial step

Summary of Contents for VRV III REYQ10PY1

Page 1: ...REYQ8 48PY1 R 410A Heat Recovery 50Hz Si37 701 ...

Page 59: ...Specifications Si37 701 48 Specifications ...

Page 105: ...Refrigerant Flow for Each Operation Mode Si37 701 94 Refrigerant Circuit ...

Page 230: ...Si37 701 Troubleshooting by Remote Controller Troubleshooting 219 ...

Page 374: ...Si37 701 Piping Diagrams Appendix 363 REYQ14P 16PY1 3D058153A S2NPL S1NPH ...

Page 375: ...Piping Diagrams Si37 701 364 Appendix REMQ8PY1 3D057743 ...

Page 376: ...Si37 701 Piping Diagrams Appendix 365 REMQ10PY1 12PY1 3D057742 ...

Page 377: ...Piping Diagrams Si37 701 366 Appendix REMQ14PY1 16PY1 3D057741 ...

Page 382: ...Si37 701 Piping Diagrams Appendix 371 1 3 BS Unit 4D057985A ...

Page 384: ...Si37 701 Wiring Diagrams for Reference Appendix 373 REYQ14 16PY1 3D056774C ...

Page 385: ...Wiring Diagrams for Reference Si37 701 374 Appendix REMQ8PY1 3D055307E ...

Page 386: ...Si37 701 Wiring Diagrams for Reference Appendix 375 REMQ10 12PY1 3D055308E ...

Page 387: ...Wiring Diagrams for Reference Si37 701 376 Appendix REMQ14P 16PY1 3D055309E ...

Page 392: ...Si37 701 Wiring Diagrams for Reference Appendix 381 FXCQ40M 50M 80M 125MVE 3D039557A ...

Page 394: ...Si37 701 Wiring Diagrams for Reference Appendix 383 FXZQ20M 25M 32M 40M 50M8V1B 3D038359 ...

Page 395: ...Wiring Diagrams for Reference Si37 701 384 Appendix FXKQ25MA 32MA 40MA 63MAVE 3D039564C ...

Page 399: ...Wiring Diagrams for Reference Si37 701 388 Appendix FXDYQ180M 200M 250MV1 ...

Page 402: ...Si37 701 Wiring Diagrams for Reference Appendix 391 FXMQ200MA 250MAVE 3D039621B ...

Page 403: ...Wiring Diagrams for Reference Si37 701 392 Appendix FXHQ32MA 63MA 100MAVE 3D039801D ...

Page 406: ...Si37 701 Wiring Diagrams for Reference Appendix 395 2 4 BS Unit 3D055928C ...

Page 423: ...Piping Installation Point Si37 701 412 Appendix ...

Page 427: ...Example of Connection R 410A Type Si37 701 416 Appendix ...

Page 433: ...Method of Checking the Inverter s Power Transistors and Diode Modules Si37 701 422 Appendix ...

Page 447: ...Si37 701 iv Index ...