Troubleshooting (OP: Unified ON/OFF Controller)

SiBE37-701

370

Troubleshooting

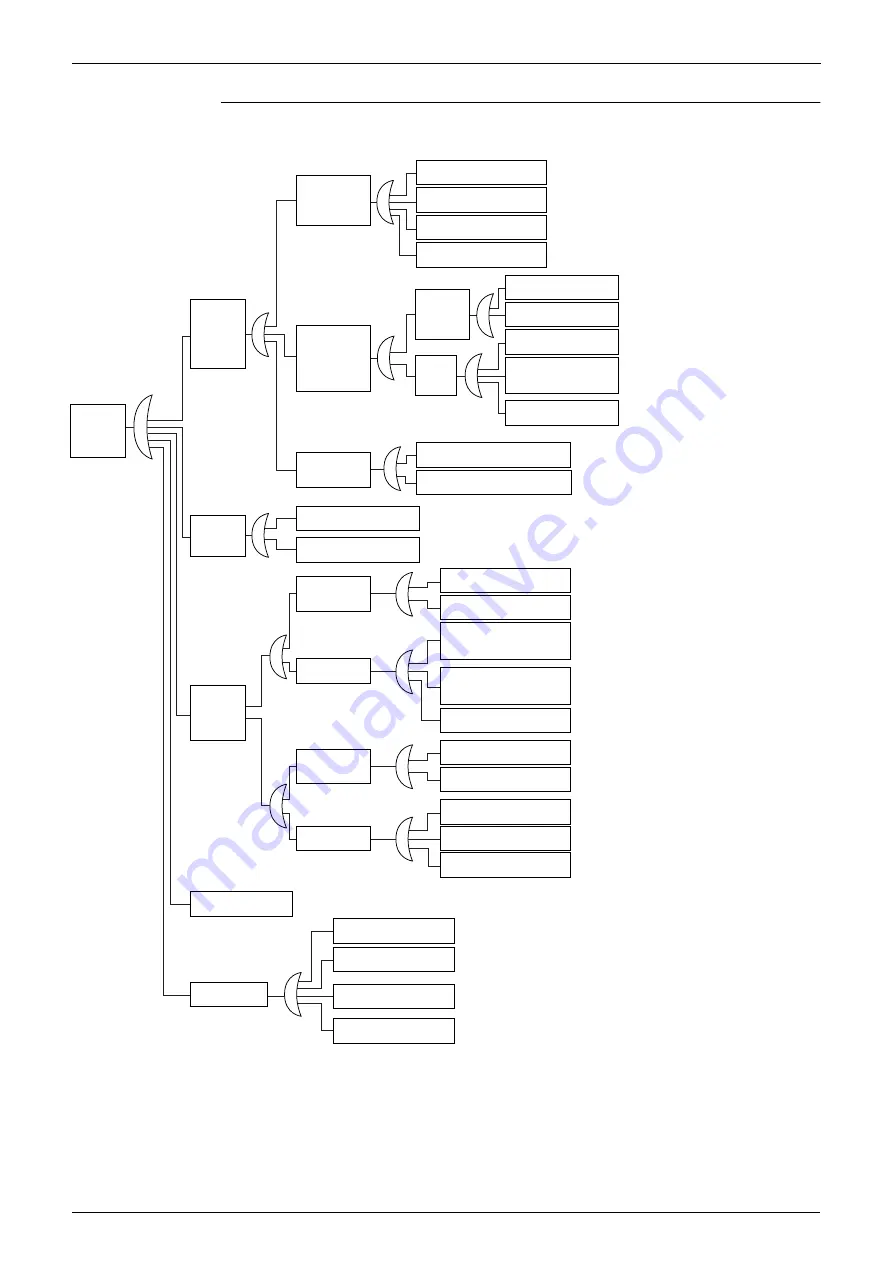

[CHECK 3] Check the Factors of Overheat Operation

Identify the defective points referring to the failure factor analysis (FTA) as follows.

Irregular piping length

Bend/collapse

(Including moisture choke)

Stop valve is closed.

4 way switch valve is in the

middle position.

Leak from hot gas bypass

valve

Subcooling

motor

operated

valve failure

Control

failure

Defective valve coil

Defective control PC board

Defective valve body

Defective valve coil

Defective valve body

Defective low pressure

sensor

Defective thermister for

suction pipe

Defective control PC board

Defective thermister for

indoor unit gas pipe

Defective thermister for

indoor unit liquid pipe

∗

1: Refer to “Low pressure protection control” (P132) for hot gas bypass control.

∗

2: Refer to P114 for subcooling electronic expansion valve control.

∗

∗

4: Superheating temperature control in heating mode is conducted by outdoor unit electronic expansion valve (EVM).

∗

5: Judgment criteria of superheat operation:

Suction gas superheating temperature: 10 degrees and over.

Discharge gas superheating temperature: 45 degrees

and over, except for immediately after starting and drooping control, etc..

(Use the above stated values as a guide. Depending on the other conditions, the unit may be normal despite the values

within the above scope.)

←

Check if coil resistance and insulation

are normal.

←

Check if coil resistance and

insulation are normal.

←

Check if the voltage property is

normal.

←

Check if the connector is connected properly.

Check if the thermister resistance property

is normal.

←

Check if the piping temperature connected

to the 4 way switch valve is normal.

←

Check if the pressure value given by the

service checker corresponding to actual

measurement value by the sensor.

←

Check if coil resistance and insulation are

normal.

←

Check if the connector is connected properly.

Check if the thermister resistance property is

normal.

←

Check if the connector is connected properly.

Check if the thermister resistance property is

normal.

←

Check if the connector is connected properly.

Check if the thermister resistance property is normal.

←

Check if coil resistance and insulation are

normal.

←

Check if the voltage property is normal.

←

Refer to [Check 7]

←

Check if the pressure value given by the

service checker corresponding to actual

measurement value by the sensor.

←

Does the piping length fall in the permissible range?

←

Corduet visual checks.

←

Remove the moisture by vacuum break. (Refer to [Check 8])

←

Check if the stop valve is open.

Faulty

discharge

pipe

temperature

control

Faulty hot

gas bypass

control

Hot gas circuit clogging

Defective solenoid

valve coil

Defective solenoid

valve body

Defective control PC board

Defective control

PC board

Defective valve coil

Defective low

pressure sensor

Defective subcool

heat exchange

outlet thermister

Defective valve

body

Faulty

subcooling

motorized

valve control

(EV2)

Superheat due to

shaft damage

Superheat due to

defective compressor

Indoor unit

motorized

valve failure

Faulty control

Faulty control

Outdoor unit

motorized

valve failure

Faulty of 4 way

switch valve

operation

[In cooling mode only]

(

∗

1)

(

∗

2)

Compressor

overheat

Refrigerant gas

shortage

Large resistance

of piping

Faulty

superheated

degree

control.

[In cooling mode]

When indoor unit

electronic

expansion valve

becomes too

narrow (

∗

3)

[In heading

mode]When

outdoor unit

electronic

expansion valve

becomes too

narrow (

∗

4)

Temperature

increase of

discharge

pipe

Summary of Contents for VRV III REYQ10PY1B

Page 1: ...REYQ8 48PY1B R 410A Heat Recovery 50Hz SiBE37 701 ...

Page 111: ...Refrigerant Flow for Each Operation Mode SiBE37 701 100 Refrigerant Circuit ...

Page 252: ...SiBE37 701 Troubleshooting by Remote Controller Troubleshooting 241 ...

Page 396: ...SiBE37 701 Piping Diagrams Appendix 385 REYQ14P 16P 3D058153B S2NPL S1NPH ...

Page 397: ...Piping Diagrams SiBE37 701 386 Appendix REMQ8P 3D057743 ...

Page 398: ...SiBE37 701 Piping Diagrams Appendix 387 REMQ10P 12P 3D057742 ...

Page 399: ...Piping Diagrams SiBE37 701 388 Appendix REMQ14P 16P 3D057741 ...

Page 400: ...SiBE37 701 Piping Diagrams Appendix 389 1 2 Indoor Unit FXFQ P ...

Page 405: ...Piping Diagrams SiBE37 701 394 Appendix 1 3 BS Unit 4D057985A ...

Page 415: ...Wiring Diagrams for Reference SiBE37 701 404 Appendix FXZQ20M 25M 32M 40M 50MV1 ...

Page 416: ...SiBE37 701 Wiring Diagrams for Reference Appendix 405 FXCQ20M 25M 32M 63MV3 ...

Page 417: ...Wiring Diagrams for Reference SiBE37 701 406 Appendix FXCQ40M 50M 80M 125MV3 ...

Page 420: ...SiBE37 701 Wiring Diagrams for Reference Appendix 409 FXDQ20M 25MV3 ...

Page 421: ...Wiring Diagrams for Reference SiBE37 701 410 Appendix FXSQ20M 25M 32M 40M 50M 63MV3 ...

Page 422: ...SiBE37 701 Wiring Diagrams for Reference Appendix 411 FXSQ80M 100M 125MV3 ...

Page 447: ...Example of connection SiBE37 701 436 Appendix ...

Page 453: ...Method of Checking the Inverter s Power Transistors and Diode Modules SiBE37 701 442 Appendix ...

Page 467: ...SiBE37 701 iv Index ...