English

10

7.

FIELD WIRING

Caution

•

All field wiring and components must be installed by a licensed

electrician and must comply with relevant local and national

regulations.

•

Be sure to use a dedicated power circuit. Never use a power sup-

ply shared by another appliance.

•

Never install a phase advancing capacitor. As this unit is equipped

with an inverter, installing a phase advancing capacitor will not only

deteriorate power factor improvement effect, but also may cause

capacitor abnormal heating accident due to high-frequency waves.

•

Only proceed with wiring work after blocking off all power.

•

Always ground wires in accordance with relevant local and

national regulations.

•

This machine includes an inverter device. Connect earth and

leave charge to eliminate the impact on other devices by reducing

noise generated from the inverter device and to prevent leaked

current from being charged in the outer hull of the product.

•

Do not connect the ground wire to gas pipes, sewage pipes, light-

ning rods, or telephone ground wires.

Gas pipes :

can explode or catch fire if there is a gas leak.

Sewage pipes :

no grounding effect is possible if hard plastic pip-

ing is used.

Telephone ground wires and lightning rods :

dangerous when

struck by lightning due to abnormal rise in electrical potential in

the grounding.

•

Be sure to install an earth leakage circuit breaker.

This unit uses an inverter, so install the earth leakage circuit

breaker that be capable of handling high harmonics in order to

prevent malfunctioning of the earth leakage circuit breaker itself.

•

Earth leakage circuit breaker which are especially for protecting

ground-faults should be used in conjunction with main switch or

fuse for use with wiring.

Note

•

Electrical wiring must be done in accordance with the wiring dia-

grams and the description herein.

•

Do not operate until refrigerant piping work is completed.

(If operated before complete the piping work, the compressor may

be broken down.)

•

Never remove thermistor, sensor or etc. when connecting power

wiring and transmission wiring.

(If operated with thermistor, sensor or etc. removed, the compres-

sor may be broken down.)

•

This product have reversed phase protection detector that only

works when the power is turned on. If there exists black out or the

power goes on and off which the product is operating, attach a

reversed phase protection circuit locally. Running the product in

reversed phase may break the compressor and other parts.

•

Attach the power wire securely. Introducing power with a missing

N-phase or with a mistaken N-phase will break the unit.

•

Never connect the power supply in reversed phase.

The unit can not operate normally in reversed phase.

If you connect in reversed phase, replace two of the three phases.

•

Make sure the electrical unbalance ratio is no greater than 2%. If

it is larger than this, the unit’s lifespan will be reduced.

If the ratio exceeds 4%, the unit will shut down and an malfunction

code will be displayed on the indoor remote controller.

•

Connect the wire securely using designated wire and fix it with

attached clamp without applying external pressure on the termi-

nal parts (terminal for power wiring, terminal for transmission wir-

ing and earth terminal).

•

If there exists the possibility of reversed phase, lose phase,

momentary blackout or the power goes on and off while the prod-

uct is operating, attach a reversed phase protection circuit locally.

Running the product in reversed phase may break the compres-

sor and other parts.

7-1 Power circuit, safety device and cable

requirements

•

A power circuit (see the following table) must be provided for con-

nection of the unit. This circuit must be protected with the required

safety devices, i.e. a main switch, a slow blow fuse on each phase

and an earth leakage circuit breaker.

•

When using residual current operated circuit breakers, be sure to

use a high-speed type (0.1 second or less) 200mA rated residual

operating current.

•

Use copper conductors only.

•

Use insulated wire for the power cord.

•

Select the power supply cable type and size in accordance with

relevant local and national regulations.

•

Specifications for local wiring are in compliance with IEC60245.

•

Use wire type H05VV when protected pipes are used.

Use wire type H07RN-F when protected pipes are not used.

7-2 Wiring Connection Example for Whole System

(Refer to figure 17)

1.

Power supply

2.

Main switch

3.

Earth leakage circuit breaker

4.

Fuse

5.

Outdoor unit

6.

COOL/HEAT selector

7.

Remote controller

8.

Indoor unit

9.

BS unit

Note

•

Make sure the weak electric wiring (i.e. for the remote controller,

between units, etc.) and the power wiring do not pass near each

other, keeping them at least 50 mm apart.

Proximity may cause electrical interference, malfunctions, and

breakage.

•

Be sure to connect the power wiring to the power wiring terminal

block and secure it as described in “

7-5 Power Wiring Connec-

tion Procedure

”.

•

Transmission wiring should be secured as described in “

7-4

Transmission Wiring Connection Procedure

”.

•

Secure wiring with clamp such as insulation lock ties to avoid con-

tact with piping.

•

Shape the wires to prevent the structure such as the EL. COMPO.

BOX lid deforming. And close the cover firmly.

•

All field wiring is to be procured on site.

7-3 Leading wire Procedure

•

The power wiring and ground wiring are passed out from the

power wiring hole on the sides, the front (knock hole) or the bot-

tom frame (knock hole) .

•

The transmission wiring is passed out from the wiring hole (knock

hole) on the front of the unit or from a piping hole.

(Refer to figure 18)

1.

Electrical wiring diagram

2.

On the back of the EL .COMPO. BOX lid.

3.

Power wiring, ground wiring (inside conduit)

4.

(When the wiring is routed out through the side panel.)

5.

Transmission wiring

6.

Pipe opening

7.

Conduit

8.

For power wiring and ground wiring

9.

Through cover

10.

Cut off the shaded zones before use.

11.

Burr

12.

Knockout hole

13.

For transmission wiring

Note

•

Open the knock holes with a hammer or the like.

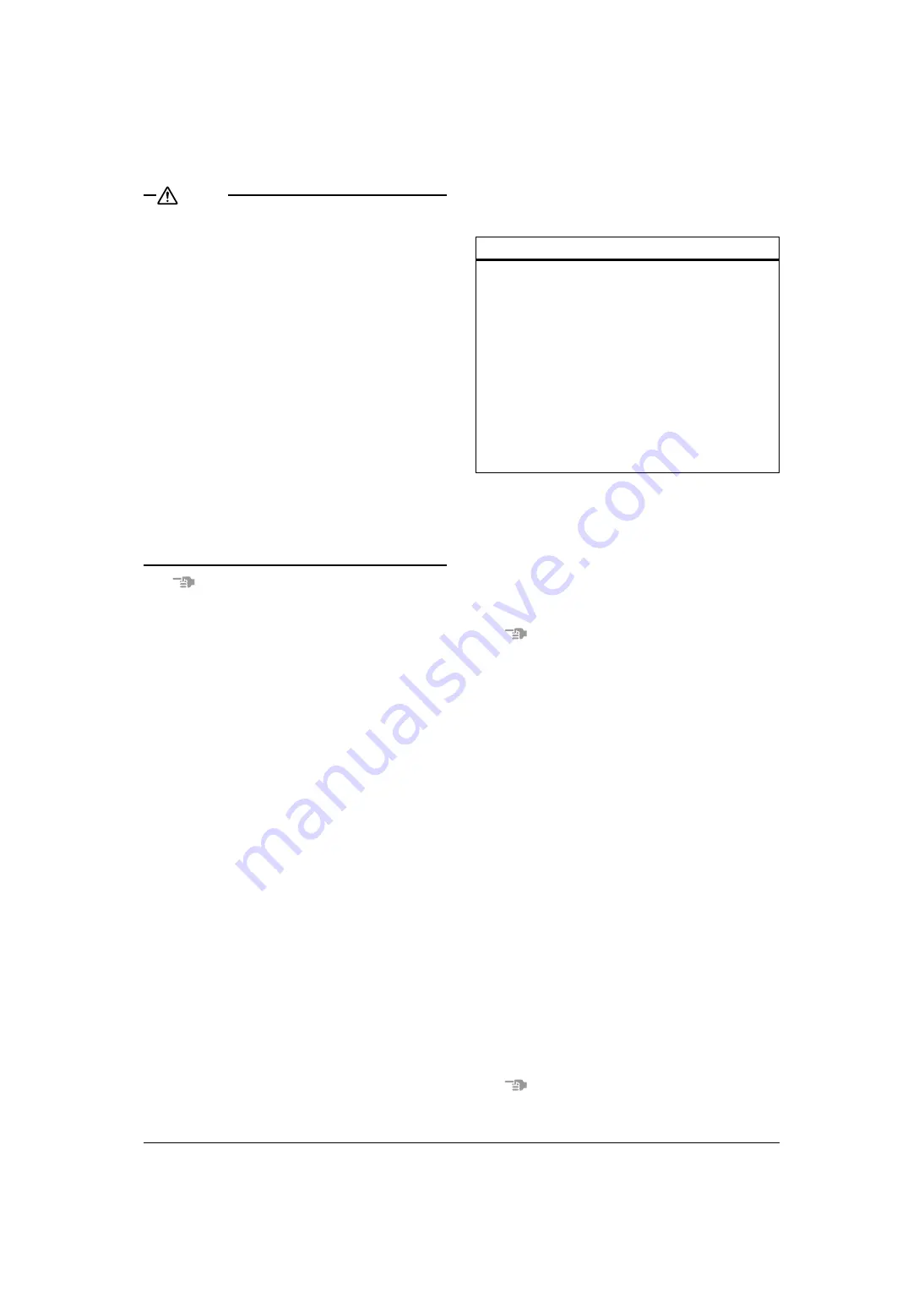

Phase and

frequency

Voltage

Minimum

circuit amp.

Recom-

mended fuses

REYQ18PY1

φ

3, 50Hz

380-415V

40.1A

45A

REYQ20PY1

φ

3, 50Hz

380-415V

41.2A

50A

REYQ22PY1

φ

3, 50Hz

380-415V

44.3A

50A

REYQ24PY1

φ

3, 50Hz

380-415V

45.4A

50A

REYQ26PY1

φ

3, 50Hz

380-415V

53.1A

60A

REYQ28PY1

φ

3, 50Hz

380-415V

54.2A

60A

REYQ30PY1

φ

3, 50Hz

380-415V

63.0A

70A

REYQ32PY1

φ

3, 50Hz

380-415V

63.0A

70A

REYQ34PY1

φ

3, 50Hz

380-415V

71.6A

80A

REYQ36PY1

φ

3, 50Hz

380-415V

72.7A

80A

REYQ38PY1

φ

3, 50Hz

380-415V

75.8A

90A

REYQ40PY1

φ

3, 50Hz

380-415V

76.9A

90A

REYQ42PY1

φ

3, 50Hz

380-415V

84.6A

100A

REYQ44PY1

φ

3, 50Hz

380-415V

85.7A

100A

REYQ46PY1

φ

3, 50Hz

380-415V

94.5A

110A

REYQ48PY1

φ

3, 50Hz

380-415V

94.5A

110A

Summary of Contents for VRV III REYQ18PY1

Page 23: ...3P201178 5 EM06A072 0702 FS ...