11

English

•

After knocking out the holes, we recommend you remove any

burrs and paint them using the repair paint to prevent rusting.

(Refer to figure 18)

•

When passing wiring through the knock holes, remove burrs

around the knock holes and protect the wiring with protective

tape.

(Refer to figure 18)

•

If small animals might enter the unit, block off any gaps (hatching

parts in figure 18) with material (field supply).

7-4 Transmission Wiring Connection Procedure

•

Referring to figure 19 connect the transmission wiring between

outdoor unit and indoor unit, outdoor unit and outdoor unit of other

system, outdoor unit and outdoor unit of same system.

(Refer to figure 19)

1.

Master unit (*)

2.

Sub unit (*)

3.

Outdoor unit A

4.

Outdoor unit B

5.

Outdoor unit C

6.

Never connect the power wire.

7.

To outdoor unit of other system

8.

Use duplex wires (No polarity)

9.

BS unit

10.

Indoor unit

11.

Indoor unit (Cooling only)

(*) : The Outdoor unit that connect the transmission wiring to BS

unit is Master unit of the multi system.

And the other units are Sub unit. (In this figure, Outdoor unit

A is the Master unit.)

Check operation in installation work, Onsite settings and so

on are done by operating the PC-bord (A1P) of Master unit.

Note

•

Do not connect the power wiring to terminals for the transmission

wiring. Doing so would destroy the entire system.

•

When connecting wires to the terminal block on the PC-board, too

much heat or tightening could damage the PC-board. Attach with care.

See the table below for the tightening torque of the transmission wiring

terminals.

•

All transmission wiring should use sheathed vinyl cord 0.75-1.25

mm

2

or cable (duplex).

•

Transmission wiring (About the symbol

~

,

see figure 19

)

should be done within the following limitations.

If they are exceeded, transmission problems may occur.

Between outdoor unit and BS (or indoor) unit

Between BS unit and indoor unit

Between outdoor unit and outdoor unit of other systems

Max. wiring length

:1,000 m

Max. total wiring length

:2,000 m

Max. no. of branches

:16

[Note]

No branch is allowed after branch (

See figure 20

)

Max. no. of outdoor units of other system

that can be connected

: 10

(Refer to figure 20)

1.

Branch

2.

Branch after branch

Between outdoor unit and outdoor unit of same system

Max. wiring length

: 30 m

•

The transmission wiring inside the EL.COMPO.BOX should be

secured using the clamp (1) as shown in figure 21.

(Refer to figure 21)

1.

In the EL.COMPO.BOX

2.

Retain to the EL.COMPO.BOX with the accessory clamp (1).

•

Outside the units, the transmission wiring must be finished simul-

taneously with the local refrigerant piping, and wound with tape

(field supply) as shown in figure 22.

(Refer to figure 22)

1.

Suction gas pipe

2.

HP/LP gas pipe

3.

Liquid pipe

4.

Insulation material

5.

Finishing tape

6.

Transmission wiring

•

Transmission wiring between outdoor units in the outdoor multi sys-

tem must be connected to terminals Q1 and Q2 (TO MULTI UNIT).

Connecting the wires to the F1, F2 (TO OUT/D UNIT) terminals

results in system malfunction.

•

Wiring to other systems should be connected to terminals F1 and

F2 (TO OUT/D UNIT) on the PC-board of the master unit. The out-

door unit that connected transmission wiring to BS (or indoor) unit

is the master unit. The others are sub unit.

7-5 Power Wiring Connection Procedure

•

Be sure to connect the power supply wiring to the power supply

terminal block and hold it in place using the included clamp as

shown in the figure 23.

•

The L1, L2, L3 and N phases of the power wiring should be

secured separately to the hook using the included clamp (1).

•

The ground wiring should be bound to the power wiring using the

included clamp (1) to prevent outside force from being applied to

the terminal area.

(Refer to figure 23)

1.

Power supply (3N~ 380-415V 50Hz)

2.

Earth leakage circuit breaker

3.

Branch switch, Overcurrent breaker

4.

Ground wire

5.

Attach insulation sleeves

6.

Power supply terminal block

7.

Ground terminal

8.

Clamp (1) (accessory)

Caution

•

Be sure to use crimp-style terminal with insulating sleeves for

connections. (See the figure below.)

•

For wiring, use the designated power wire and connect firmly,

then secure to prevent outside pressure being exerted on the ter-

minal board.

•

Use an appropriate screwdriver for tightening the terminal screws.

A screwdriver with a small head will strip the head and make

proper tightening impossible.

•

Over-tightening the terminal screws may break them.

See the following table for the tightening torque of the terminal

screws.

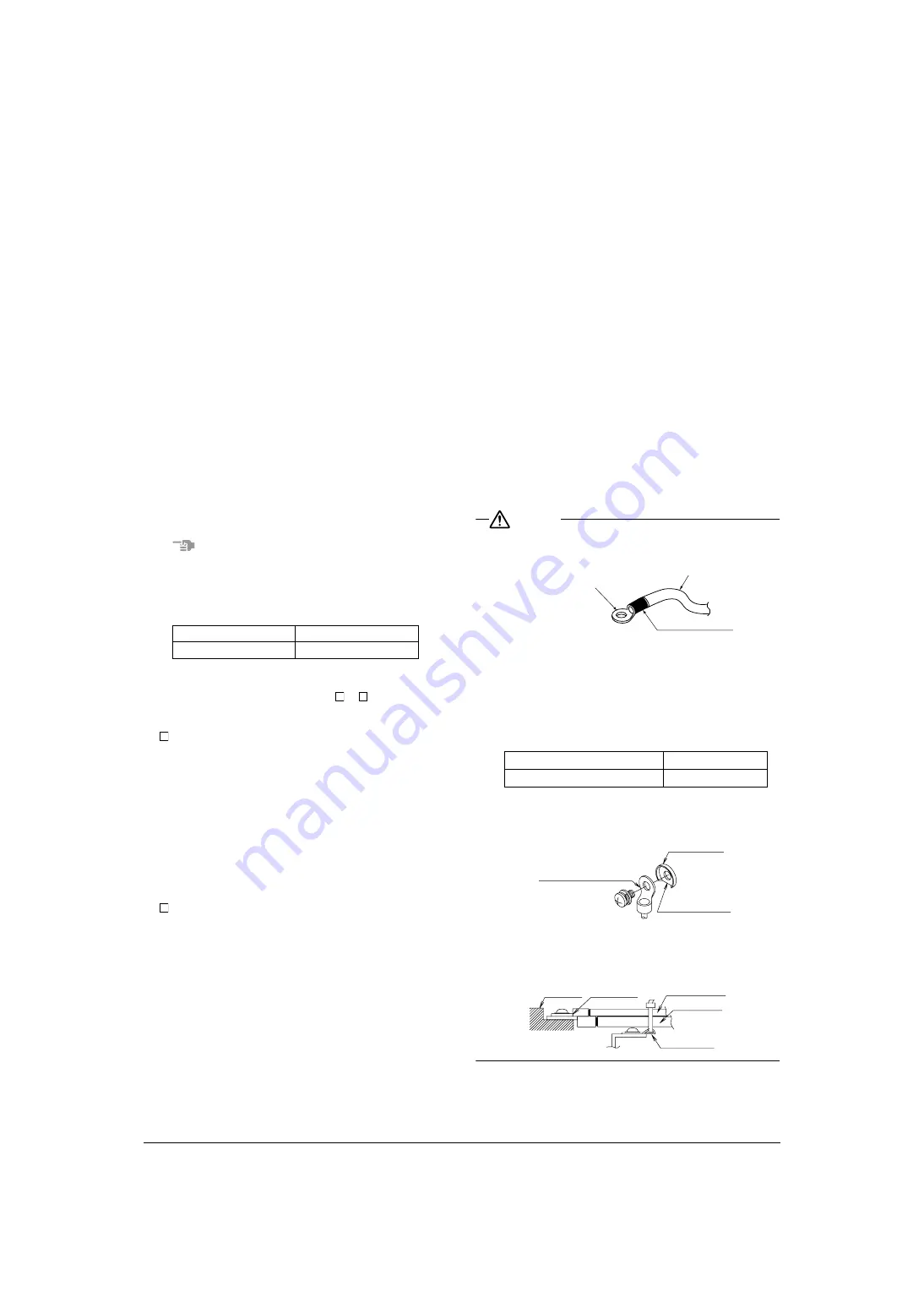

•

When pulling the ground wire out, wire it so that it comes through

the cut out section of the cup washer. (See the figure below.) An

improper ground connection may prevent a good ground from

being achieved.

•

When two wires are connected to a single terminal, connect them

so that the rear sides of the crimp contacts face each other. Also,

make sure the thinner wire is on top, securing the two wires simul-

taneously to the resin hook using the included clamp (1).

Screw size

Tightening torque (N · m)

M3.5 (A1P)

0.80 - 0.96

1

2

1

2

Screw size

Tightening torque (N·m)

M8 Power terminal, ground terminal

5.5 ~7.3

Power wire

Crimp-style terminal

Insulating sleeve

Crimp-style terminal

Cup washer

Cut out section

Terminal

block

Crip style

terminal

Wire : narrow

Wire : thick

Resin hook

Summary of Contents for VRV III REYQ18PY1

Page 23: ...3P201178 5 EM06A072 0702 FS ...