17 Commissioning

Installation and operation manual

37

RK RKXYQ8T7Y1B

VRV IV compressor unit for indoor installation

4P499900-1B – 2021.12

Drainage

Make sure drainage flows smoothly.

Possible consequence:

Condensate water might drip.

External static pressure

Make sure the external static pressure is set.

Possible consequence:

Insufficient cooling or heating.

17.3

Checklist during commissioning

To perform a

test run

.

17.3.1

About the test run

NOTICE

Make sure to carry out the test run after the first

installation. Otherwise, the malfunction code

will be

displayed on the user interface and normal operation or

individual indoor unit test run cannot be carried out.

The procedure below describes the test operation of the complete

system. This operation checks and judges following items:

▪ Check of wrong wiring (communication check with indoor units

and heat exchanger unit).

▪ Check of the stop valves opening.

▪ Check of wrong piping.

Example:

Gas or liquid pipes switched.

▪ Judgement of piping length.

Abnormalities on indoor units cannot be checked for each unit

separately. After the test operation is finished, check the indoor units

one by one by performing a normal operation using the user

interface. Refer to the indoor unit installation manual for more details

concerning the individual test run.

INFORMATION

▪ It may take 10 minutes to achieve a uniform refrigerant

state before the compressor starts.

▪ During the test operation, the refrigerant running sound

or the magnetic sound of a solenoid valve may become

loud and the display indication may change. These are

not malfunctions.

17.3.2

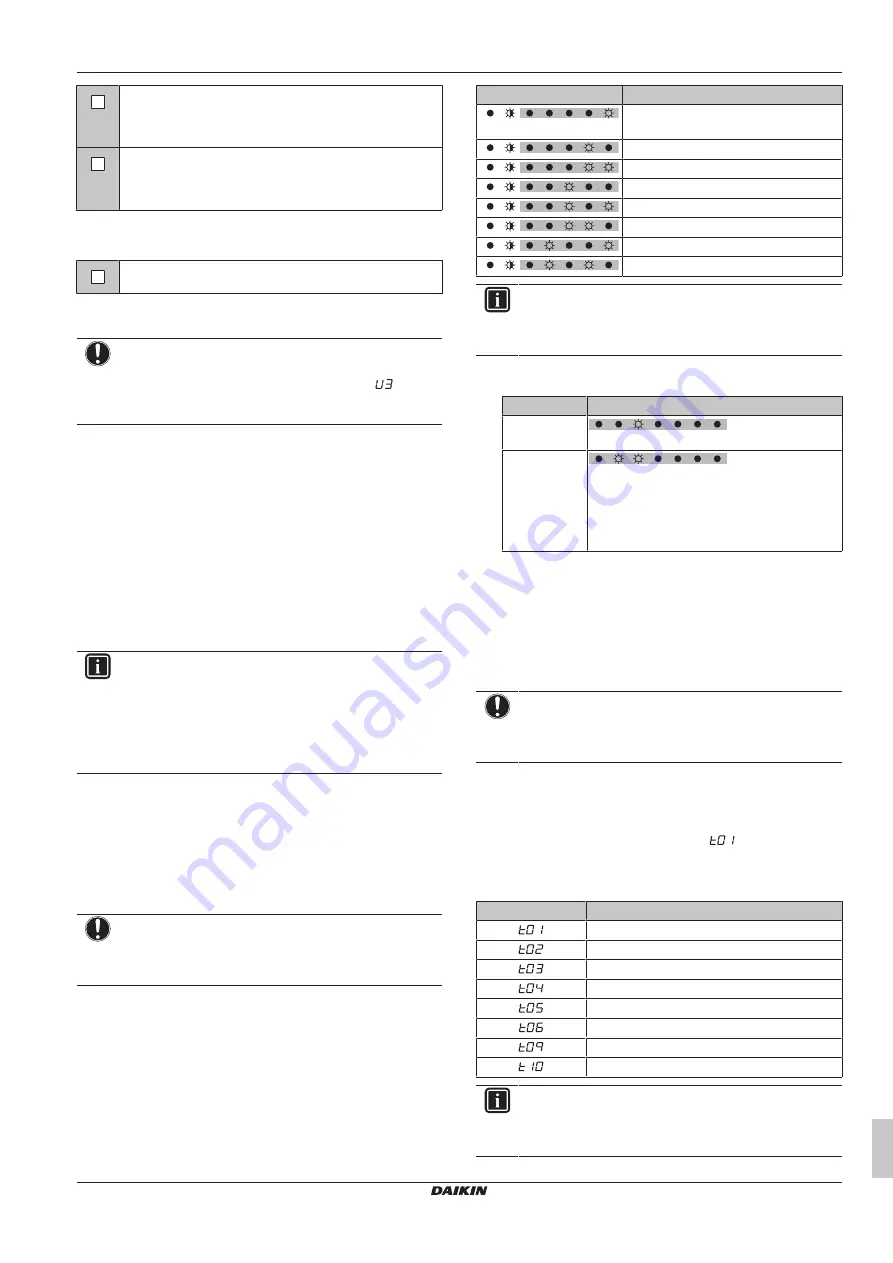

To perform a test run (7-LEDs display)

(in case of 5 HP)

1

Make sure all field settings you want are set; see

29].

2

Turn ON the power to the compressor unit, heat exchanger unit,

and the connected indoor units.

NOTICE

Be sure to turn ON the power 6 hours before operation in

order to have power running to the crankcase heater and

to protect the compressor.

3

Make sure the default (idle) situation is existing (H1P is OFF);

see

"16.1.4 To access mode 1 or 2"

30]. Push BS4 for 5

seconds or more. The unit will start test operation.

Result:

The test operation is automatically carried out, the

compressor unit H2P flashes and the indication "Test operation"

and "Under centralised control" will display on the user interface

of indoor units.

Steps during the automatic system test run procedure:

Step

Description

Control before start up (pressure

equalisation)

Cooling start up control

Cooling stable condition

Communication check

Stop valve check

Pipe length check

Pump down operation

Unit stop

INFORMATION

During the test operation, it is not possible to stop the unit

operation from a user interface. To abort the operation,

press BS3. The unit will stop after ±30 seconds.

4

Check the test operation results on the compressor unit 7‑LEDs

display.

Completion

Description

Normal

completion

Abnormal

completion

"17.3.4 Correcting after abnormal

38] to take

actions for correcting the abnormality. When

the test operation is fully completed, normal

operation will be possible after 5 minutes.

17.3.3

To perform a test run (7-segment display)

(in case of 8 HP)

1

Make sure all field settings you want are set; see

2

Turn ON the power to the compressor unit, heat exchanger unit,

and the connected indoor units.

NOTICE

Be sure to turn ON the power 6 hours before operation in

order to have power running to the crankcase heater and

to protect the compressor.

3

Make sure the default (idle) situation is existing; see

30]. Push BS2 for 5 seconds or more.

The unit will start test operation.

Result:

The test operation is automatically carried out, the

compressor unit display will indicate "

" and the indication

"Test operation" and "Under centralised control" will display on

the user interface of indoor units.

Steps during the automatic system test run procedure:

Step

Description

Control before start up (pressure equalisation)

Cooling start up control

Cooling stable condition

Communication check

Stop valve check

Pipe length check

Pump down operation

Unit stop

INFORMATION

During the test operation, it is not possible to stop the unit

operation from a user interface. To abort the operation,

press BS3. The unit will stop after ±30 seconds.