14 Piping installation

Installation and operation manual

22

RK RKXYQ8T7Y1B

VRV IV compressor unit for indoor installation

4P499900-1A – 2020.10

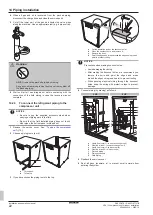

4

When all gas and oil is recovered from the pinched piping,

disconnect the charge hose and close the service ports.

5

Cut off the lower part of the gas and liquid stop valve pipes

along the black line. Use an appropriate tool (e.g. a pipe cutter).

WARNING

NEVER remove the pinched piping by brazing.

Any gas or oil remaining inside the stop valve may blow off

the pinched piping.

6

Wait until all oil has dripped out before continuing with the

connection of the field piping in case the recovery was not

complete.

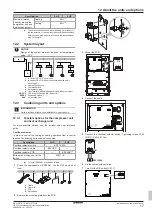

14.2.3

To connect the refrigerant piping to the

compressor unit

NOTICE

▪ Be sure to use the supplied accessory pipes when

carrying out piping work in the field.

▪ Be sure that the field installed piping does not touch

other pipes, the bottom panel or side panel.

1

Remove the service cover. See

18].

2

Choose a piping route (a or b).

b

a

a

a

To the back

b

To the top

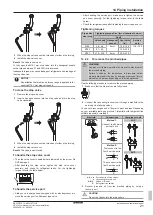

3

If you have chosen the piping route to the top:

a b c d

a

Cut the insulation (under the knockout hole).

b

Hit on the knockout hole, and remove it.

c

Remove the burrs.

d

Paint the edges and areas around the edges using repair

paint to prevent rusting.

NOTICE

Precautions when making knockout holes:

▪ Avoid damaging the casing.

▪ After making the knockout holes, we recommend you

remove the burrs and paint the edges and areas

around the edges using repair paint to prevent rusting.

▪ When passing electrical wiring through the knockout

holes, wrap the wiring with protective tape to prevent

damage.

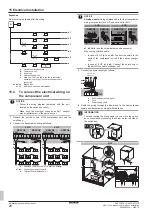

4

Connect piping (by brazing) as follows:

8 HP

5 HP

c

d

d

c

b

a

b

a

3 1

2

3

2

1

a

Liquid line (circuit 1: to heat exchanger unit)

b

Gas line (circuit 1: to heat exchanger unit)

c

Liquid line (circuit 2: to indoor units)

d

Gas line (circuit 2: to indoor units)

1

Pinched piping

2

Piping accessory

3

Field piping

5

Reattach the service cover.

6

Seal all gaps (example: a) to prevent small animals from

entering the system.