14 Piping installation

Installation and operation manual

25

RK RKXYQ8T7Y1B

VRV IV compressor unit for indoor installation

4P499900-1A – 2020.10

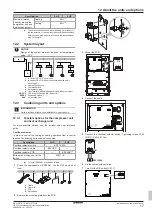

a

b

a

Insulation material

b

Caulking etc.

14.4

Charging refrigerant

14.4.1

Precautions when charging refrigerant

WARNING

▪ ONLY use R410A as refrigerant. Other substances

may cause explosions and accidents.

▪ R410A contains fluorinated greenhouse gases. Its

global warming potential (GWP) value is 2087.5. Do

NOT vent these gases into the atmosphere.

▪ When charging refrigerant, ALWAYS use protective

gloves and safety glasses.

NOTICE

If the power of some units is turned off, the charging

procedure cannot be finished properly.

NOTICE

Be sure to turn ON the power 6 hours before operation in

order to have power running to the crankcase heater and

to protect the compressor.

NOTICE

If operation is performed within 12 minutes after the

compressor unit, heat exchanger unit and indoor units are

turned on, the compressor will not operate before the

communication is established in a correct way between the

compressor unit, heat exchanger unit and indoor units.

NOTICE

Before starting charging procedures:

▪ In case of 5 HP: Check if the 7‑LEDs display is as

normal (see

30]), and there

is no malfunction code on the user interface of the

indoor unit. If a malfunction code is present, see

"19.1 Solving problems based on error codes"

38].

▪ In case of 8 HP: Check if the 7‑segment display

indication of the compressor unit A1P PCB is as normal

(see

30]). If a malfunction

code is present, see

"19.1 Solving problems based on

38].

NOTICE

Make sure all connected units (heat exchanger unit +

indoor units) are recognised (setting [1‑5]).

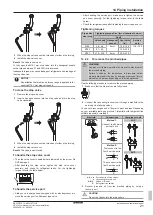

14.4.2

To determine the additional refrigerant

amount

Formula:

R=[(X

1

×

Ø12.7

)×0.12+(X

2

×

Ø9.5

)×0.059+(X

3

×

Ø6.4

)×0.022]×A+B

R

Additional refrigerant to be charged [in kg and rounded off

to 1 decimal place]

X

1...3

Total length [m] of liquid piping size at

Øa

A+B

Parameters A and B

Parameters A and B

:

Model

A

B

RKXYQ5

0.8 kg

3.1 kg

RKXYQ8

1.0 kg

2.6 kg

Metric piping.

When using metric piping, replace the weight factors

in the formula by the ones from the following table:

Inch piping

Metric piping

Piping

Weight factor

Piping

Weight factor

Ø6.4 mm

0.022

Ø6 mm

0.018

Ø9.5 mm

0.059

Ø10 mm

0.065

Ø12.7 mm

0.12

Ø12 mm

0.097

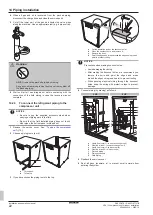

14.4.3

To charge refrigerant

Charging refrigerant consists of 2 stages:

Stage

Description

Stage 1: Pre-charging Recommended in case of larger systems.

Can be skipped, but charging will take longer

then.

Stage 2: Manual

charging

Only necessary if the determined additional

refrigerant amount is

not reached

yet by

pre-charging.

Stage 1: Pre-charging

Summary – Pre-charging

:

Refrigerant bottle

Connected to the service ports of the stop

valves. Which stop valves to use depends

on the circuits you choose to pre-charge to:

▪ Circuits 1 and 2 together (manifold with

refrigerant line splitters required).

▪ First circuit 1, then circuit 2 (or vice versa).

▪ Only circuit 1

▪ Only circuit 2

Stop valves

Closed

Compressor

Does NOT operate

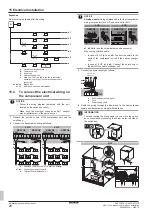

1

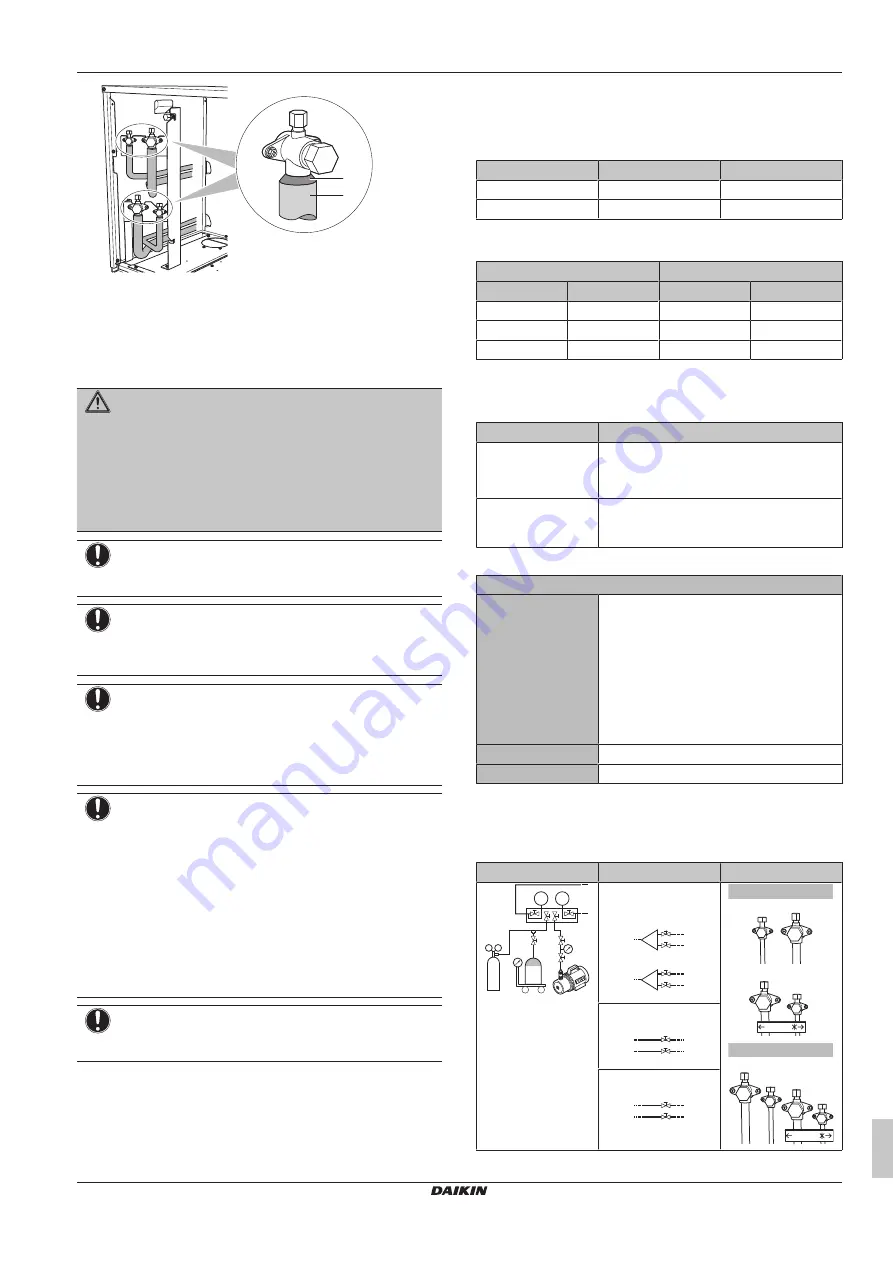

Connect as shown (choose one of the possible connections).

Make sure that all compressor unit stop valves, as well as valve

A are closed.

Possible connections:

Manifold

Connections

Compressor unit

p< p>

R410A

N2

b

c

e

a

d

B

A

Circuit 1 and 2

together

C

g

h

A

f

i

B

C

C

C

D

D

RDXYQ

RDXYQ

h

h

i

i

g

g

f

f

5 HP

8 HP

Only circuit 1

i

B

h

A

C

C

Only circuit 2

C

C

f

B

g

A

a

Pressure reducing valve