18 Hand-over to the user

Installation and operation manual

38

RK RKXYQ8T7Y1B

VRV IV compressor unit for indoor installation

4P499900-1A – 2020.10

NOTICE

Be sure to turn ON the power 6 hours before operation in

order to have power running to the crankcase heater and

to protect the compressor.

3

Make sure the default (idle) situation is existing; see

30]. Push BS2 for 5 seconds or more. The unit

will start test operation.

Result:

The test operation is automatically carried out, the

compressor unit display will indicate "

" and the indication

"Test operation" and "Under centralised control" will display on

the user interface of indoor units.

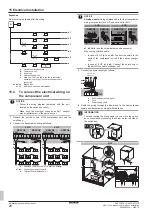

Steps during the automatic system test run procedure:

Step

Description

Control before start up (pressure equalisation)

Cooling start up control

Cooling stable condition

Communication check

Stop valve check

Pipe length check

Pump down operation

Unit stop

INFORMATION

During the test operation, it is not possible to stop the unit

operation from a user interface. To abort the operation,

press BS3. The unit will stop after ±30 seconds.

4

Check the test operation results on the compressor unit

7‑segment display.

Completion

Description

Normal

completion

No indication on the 7‑segment display (idle).

Abnormal

completion

Indication of malfunction code on the

7‑segment display.

Refer to

"Correcting after abnormal completion

correcting the abnormality. When the test

operation is fully completed, normal operation

will be possible after 5 minutes.

17.3.4

Correcting after abnormal completion of

the test run

The test operation is only completed if there is no malfunction code

displayed. In case of a displayed malfunction code, perform

correcting actions as explained in the malfunction code table. Carry

out the test operation again and confirm that the abnormality is

properly corrected.

INFORMATION

If a malfunction occurs:

▪ In case of 5 HP: The error code is displayed on the

user interface of the indoor unit.

▪ In case of 8 HP: The error code is displayed on the

compressor unit's 7‑segments display and on the user

interface of the indoor unit.

INFORMATION

Refer to the installation manual of the indoor unit for

detailed malfunction codes related to indoor units.

17.3.5

Operating the unit

Once the units are installed and test operation of compressor unit,

heat exchanger unit and indoor units is finished, the operation of the

system can start.

For operating the indoor unit, the user interface of the indoor unit

should be switched ON. Refer to the indoor unit operation manual for

more details.

18

Hand-over to the user

Once the test run is finished and the unit operates properly, please

make sure the following is clear for the user:

▪ Make sure that the user has the printed documentation and ask

him/her to keep it for future reference. Inform the user that he can

find the complete documentation at the URL mentioned earlier in

this manual.

▪ Explain the user how to properly operate the system and what to

do in case of problems.

▪ Show the user what to do for the maintenance of the unit.

19

Troubleshooting

19.1

Solving problems based on error

codes

In case of a displayed malfunction code, perform correcting actions

as explained in the malfunction code table.

After correcting the abnormality, press BS3 to reset the malfunction

code and retry operation.

INFORMATION

If a malfunction occurs:

▪ In case of 5 HP: The error code is displayed on the

user interface of the indoor unit.

▪ In case of 8 HP: The error code is displayed on the

compressor unit's 7‑segments display and on the user

interface of the indoor unit.

INFORMATION

If a malfunction occurs, the error code is displayed on the

outdoor unit's 7‑segments display and on the user interface

of the indoor unit.

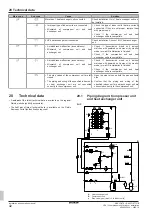

In case of 8 HP: The error code on the compressor unit will indicate

a main malfunction code and a sub code. The sub code indicates

more detailed information about the malfunction code. The main

code and sub code will be displayed intermittent (with an interval of

1 second).

Example:

▪ Main code:

▪ Sub code: