3

|

Components

Service manual

304

REYQ8~20+REMQ5U7Y1B

VRV IV+ Heat Recovery

ESIE18-15B – 2020.05

For the Y11S and Y12S valves

3

Connect the service monitoring tool to the unit and check the pressure

difference between the high and low pressure. Once the pressure difference

between the high and low pressure exceeds 0,3 MPa and the compressor is

running, Y11S and Y12S are energized.

4

Check with a contact thermometer if the flow through the oil return valve

corresponds with the flow shown in the flow diagram. (See

401]).

Is the flow correct?

Action

Yes

Oil return valve is OK. Return to the

troubleshooting of the specific error

and continue with the next procedure.

No

Replace the body of the oil return valve,

see

Problem solved?

After all checking procedures listed above have been performed:

Is the problem solved?

Action

Yes

No further actions required.

No

Return to the troubleshooting of the

specific error and continue with the

next procedure.

3.13.2 Repair procedures

To remove the oil return valve coil

Prerequisite:

Stop the unit operation via the central controller.

Prerequisite:

Turn OFF the respective circuit breaker.

Prerequisite:

Remove the required plate work, see

315].

Prerequisite:

If needed, remove any parts to create more space for the removal of

the oil return valve coil.

1

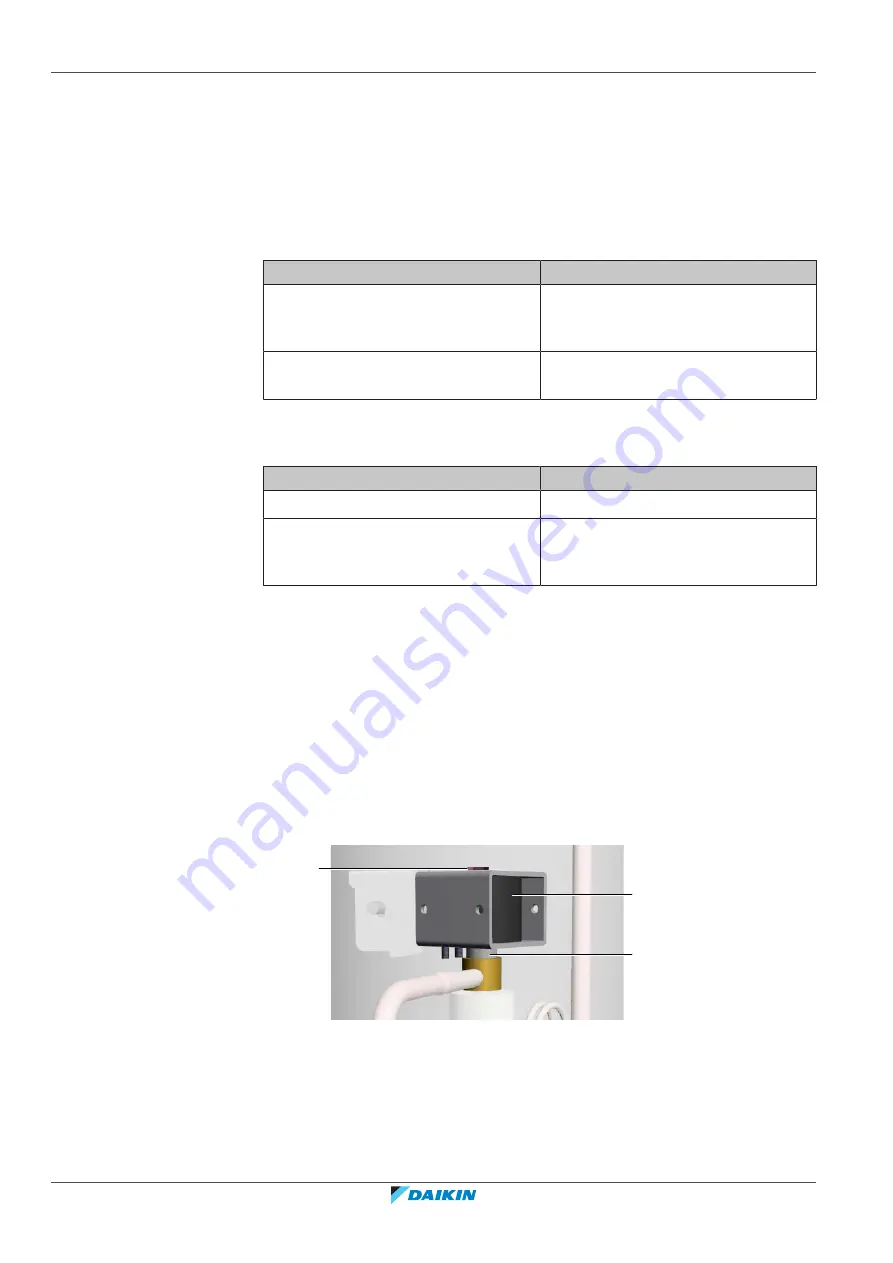

Remove the screw and remove the oil return valve coil from the oil return

valve body.

b

c

a

a

Screw

b

Valve coil

c

Valve body

2

Cut all tie straps that fix the oil return valve coil harness.

3

Disconnect the oil return valve coil connector from the appropriate PCB.

4

To install the oil return valve coil, see

Summary of Contents for VRV IV+

Page 473: ......

Page 474: ......

Page 475: ......

Page 476: ...ESIE18 15B 2020 05 Copyright 2020 Daikin Verantwortung für Energie und Umwelt ...